What is a Checkweigher? A Comprehensive Guide to Precision Weighing in Production Lines

- Share

- Issue Time

- Jul 11,2025

Summary

Discover how checkweighers can enhance your production line’s quality control, ensure compliance, and boost efficiency. Learn about their benefits, types, and how to choose the right one for your industry.

In today's fast-paced manufacturing environments, ensuring product quality and consistency is paramount. One essential tool that helps achieve this is the checkweigher. But what exactly is a checkweigher, and why is it so crucial for industries ranging from food processing to pharmaceuticals? In this guide, we'll explore the ins and outs of checkweighers, their benefits, and how they can enhance your production line. We'll also introduce you to our company, a leader in precision weighing solutions, and how our expertise can help you achieve your production goals.

Introduction to Checkweighers

A checkweigher is a specialized weighing machine used to verify the weight of packaged products during the manufacturing process. Unlike standard scales that simply display weight, a checkweigher system compares the measured weight to a pre-set target weight or weight range. They provide visual or audible feedback to operators when a product is within the target range. It ensures that each product meets the specified weight requirements, helping manufacturers maintain quality control, comply with regulations, and reduce waste. Checkweigher machines are commonly used in industries such as food and beverage, pharmaceuticals, cosmetics, and logistics, where precision and consistency are critical.

A dynamic checkweigher can be either static or dynamic (in-motion). Static checkweighers require manual placement of products on the scale, while dynamic checkweighers automatically weigh products as they move along a conveyor belt. The latter is particularly valuable for high-speed production lines, offering efficiency and accuracy without slowing down operations.

How Does a Checkweigher Scale Work?

Checkweighers use a combination of hardware and software to perform their functions. The scale's load cell detects the weight of the item and sends the measurement to the internal computer or controller. Inline checkweighers have a predetermined target weight or weight range stored in their memory. The controller compares the measured weight of the item to this target weight. Based on the comparison, the scale's software determines if the item is within the acceptable range. If the measured weight falls within the acceptable range, the item is considered correct. If it deviates from the target weight, the item is flagged as either underweight or overweight.

Depending on the industry and application, the scale may trigger various actions. In a food production line, an underweight package might be rejected or diverted for reweighing or corrective action. In logistics, overweight items might be redirected for further inspection.

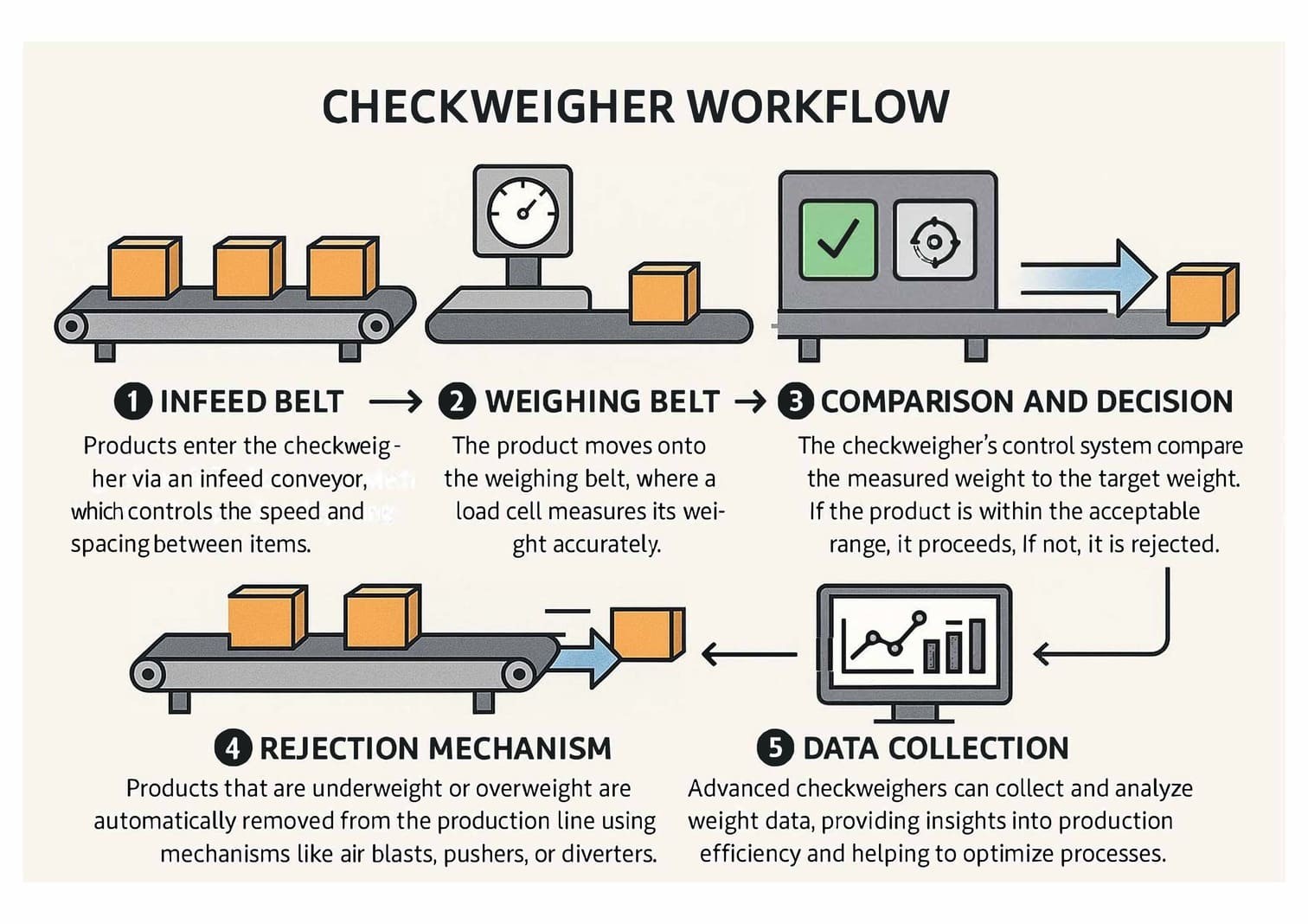

Here's a step-by-step breakdown of how a typical dynamic checkweigher functions:

1. Infeed Belt

Products enter the checkweigher combination system via an infeed conveyor, which controls the speed and spacing between items.2. Weighing Belt

The product moves onto the weighing belt, where a load cell measures its weight accurately.3. Comparison and Decision

The checkweigher scales' control system compares the measured weight to the target weight. If the product is within the acceptable range, it proceeds; if not, it is rejected.4. Rejection Mechanism

Products that are underweight or overweight are automatically removed from the production line using mechanisms like air blasts, pushers, or diverters.5. Data Collection

Advanced checkweighers can collect and analyze weight data, providing insights into production efficiency and helping to optimize processes.

Types of Checkweighers

Checkweighers come in various types to suit different production needs:

● Static Checkweighers: Ideal for lower-volume production or spot-checking, these require manual operation.

● Dynamic Checkweighers: Designed for high-speed, automated production lines, these are the most common in industrial settings.

● Combination Checkweighers: These integrate additional inspection technologies, such as metal detection or X-ray, for comprehensive quality control.

Choosing the right type depends on your production speed, product type, and specific industry requirements. For example, food processors might opt for a combination system to ensure both weight accuracy and contaminant detection.

Benefits of Using a Checkweigher Combination System

Integrating a checkweigher system into your production line offers numerous advantages:

● Quality Control

Ensures every product meets weight specifications, reducing the risk of underfilled or overfilled packages. In industries like pharmaceuticals and food production, maintaining consistent product weights is vital to ensure the quality, safety, and efficacy of products. Checkweighers help identify variations that could result from factors such as ingredient inconsistencies or production errors. Checkweighers with labeling systems make the process of portioning and package labeling quicker and more efficient.● Regulatory Compliance

Helps meet industry standards and legal requirements. Dynamic checkweighers assist businesses in adhering to these regulations and avoiding potential legal issues, such as the FDA's guidelines for food packaging or pharmaceutical dosing.● Cost Savings and Consumer Satisfaction

Minimizes product giveaway (overfilling) and reduces waste by catching underweight products before they reach consumers. In sectors like retail, accurate product weights contribute to customer satisfaction. Consumers expect to receive the exact quantity of product they paid for, and checkweighing solutions help businesses meet this expectation.● Efficiency

Automates the weighing process, increasing production speed and reducing the need for manual checks. Meanwhile, a high-speed checkweigher identifies underweight or overweight items quickly, which helps prevent defective products from entering the market, reducing waste and production costs. Manufacturers rely on these devices to ensure timely and accurate production cycles.● Data Insights

Industrial checkweighers provide real-time data that manufacturers can analyze to identify patterns and trends in their production processes. This data can help streamline operations, improve overall efficiency, and allow businesses to identify and correct quality issues quickly.● Inventory Management

Logistics and warehousing benefit from accurate measurements for proper inventory management. Checkweighers help prevent overstocking or understocking by ensuring that products are correctly measured and accounted for.Applications of Industrial Checkweigher

Checkweighers are versatile and can be used across various industries:

● Food and Beverage Checkweighers

Ensures packaged goods like snacks, canned foods, and beverages meet weight requirements and labeling standards.

● Pharmaceuticals

Verifies the weight of tablets, capsules, and packaged medicines to ensure dosage accuracy, such as a capsule checkweigher, a hygienic checkweigher.

● Cosmetics and Personal Care

Checks the weight of products like creams, lotions, and makeup to maintain consistency.● Logistics and Warehousing

Weighs parcels and shipments to ensure accurate billing and compliance with shipping regulations.In each of these sectors, checkweighers play a critical role in maintaining product integrity and customer satisfaction.

How to Choose the Right Checkweigher

When selecting a checkweigher, consider the following factors:

● Application Requirements

Determine the specific application requirements, such as the type of products to be weighed, production volume, desired weighing accuracy, and available space.● Checkweigher Types

Choose between in-motion checkweighers for high-speed production lines and static checkweighers for smaller volume processes or individual product inspection.● Key Specifications

Consider specifications such as weighing range, accuracy class, conveyor speed, weight resolution, and rejection mechanism type.● Reliability and Durability

Select a checkweigher with proven reliability and durability to ensure consistent performance and minimize downtime.● Brand and Supplier Reputation

Choose a reputable brand and supplier that can provide quality products, reliable customer support, and timely after-sales service.● Cost Analysis and Budget Planning

Conduct a cost analysis, considering not only the initial purchase price but also factors like installation, maintenance, calibration, and potential future upgrades.Why Choose SameGram for All Your Fill Checkweigher Needs?

When it comes to precision weighing solutions, we stand out as a trusted leader in the industry. With years of experience and a commitment to innovation, we offer a range of checkweighers designed to meet the unique needs of your production line. Learn more about our journey and expertise on our About Us page or explore our company profile.

● Expertise: Our team of engineers and technicians has extensive knowledge in designing and implementing checkweighing systems for various industries.

● Customization: We understand that every production line is different. That's why we offer tailored solutions to fit your specific requirements.

● Reliability: Our automatic checkweigher machines are built to last, with robust construction and advanced technology that ensures consistent performance.

● Customer Support: From installation to maintenance, our dedicated support team is here to ensure your checkweigher operates at peak efficiency.

How to Integrate an Automatic Checkweigher Machine into Your Production Line?

Adding a checkweigher to your production line is a strategic investment that can yield significant returns. Here are some key considerations for seamless integration:

● Line Speed: Ensure the checkweigher can handle your production speed without causing bottlenecks.

● Product Type: Choose a model that accommodates your product's size, shape, and packaging.

● Space Constraints: Consider the physical footprint of the checkweigher and how it fits into your existing layout.

● Data Integration: Opt for a system that can integrate with your existing ERP or production management software for real-time data analysis.

We offer consultation services to help you select and integrate the perfect checkweigher for your needs. Our experts will work with you to ensure a smooth installation and optimal performance.

Conclusion

A checkweigher is more than just a weighing machine; it's a vital component of any quality-driven production line. By ensuring that every product meets weight specifications, checkweighers help manufacturers maintain quality, comply with regulations, and optimize efficiency. Whether you're in food processing, pharmaceuticals, or logistics, investing in a reliable checkweigher can make all the difference.

Explore our range of products and discover how we can help elevate your production line to new heights. Contact us today for a consultation or to request a quote.

Related Hot-sale Checkweigher

SC3-10070L80 is a heavy duty checkweigher ideal for large items up to 80 kg. This machine is also known as roller checkweigher.

SC3-L-12080S60 is one of the best parcel weighing scales for large-items up to 60kg.,which can be integrated into DWS system.

The SC2-L-6055S5 is a logistics scale for parcel weighing under 5kg . Designed for fast, accurate weighing out logistics,

WSS-5012L2 is a compact weight sorter machine designed to ensure stable output and quality control. ideal for fish and meat.

SCL-8050L30 is an advanced automatic price weigh label machine with dynamic weighing, label editing, and MES/ERP integration.