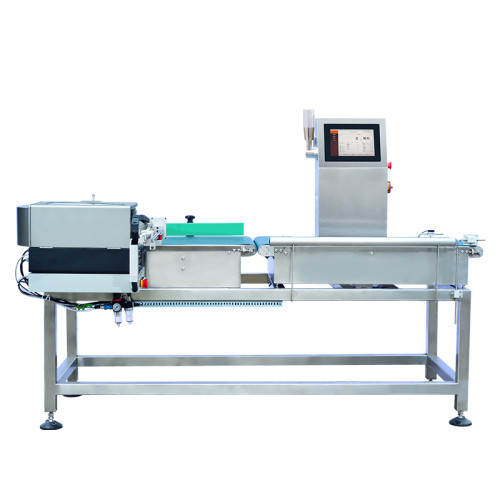

Automated Weighing and Labeling Machine for Carton Side Labeling SCL-8050L30

- Model

- SCL-8050L30

Item specifics

- Weighting range

- 10-30kg

- Weighting accuracy

- ±0.5-2g

- Labeling speed

- 15pcs/min

- Weighting section size

- L 800mm*W 300mm

- Applicable product size

- L≤500mm; W≤500mm

- Labeling acurracy

- ±5-10mm

Review

Description

Detail Information

Automated Weighing and Labeling Machine for Carton Side Labeling SCL-8050L30

Introduction

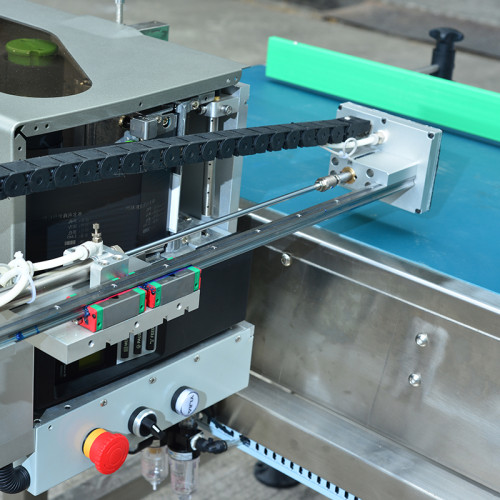

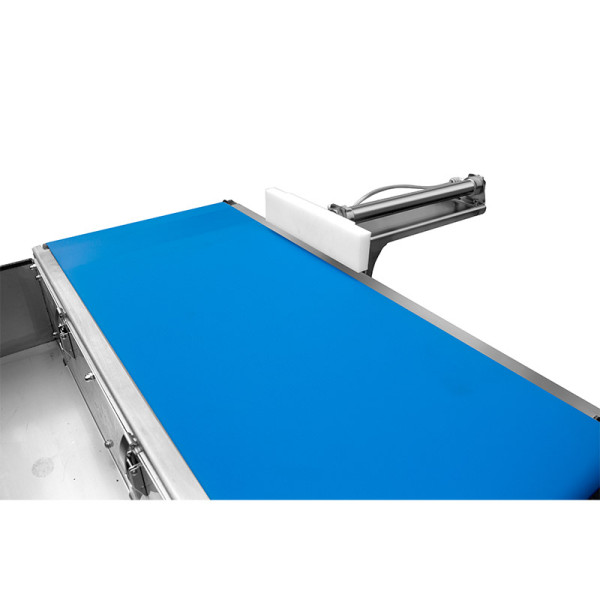

The SCL-8050L30 is an automated weighing and labelling machine for precise carton side labeling in food, retail, and consumer goods. This weighing and labeling automation system combines accurate weighing, real-time label printing, and barcode application for products up to 30 kg. It supports fully customizable labels, adjustable labeling direction, and multiple modes, making it ideal for various flat-surfaced cartons. With integrated weighing and labelling software and a reliable weighing and labeling machine setup, it ensures fast, accurate, and flexible carton processing on production lines. The system also functions as a complete carton weighing and labeling solution for modern manufacturing.

Automated Weighing and Labeling Machine for Carton Side Labeling SCL-8050L30

Features

Automated Weighing and Labeling Machine for Carton Side Labeling SCL-8050L30 Technical Parameters

| Product model | SCL-8050L30 | |

| Weighting range | 10-30kg | |

Weighting section size | L 800mm*W 300mm | |

| Case material | 304 stainless steel | |

Display division | 1g | |

| Weighting accuracy | ±0.5-2g | |

| Applicable product size | L≤500mm; W≤500mm | |

Storage formula | 100 types | |

| Power supply | AC220V±10% | |

Labeling speed | 15pcs/min | |

Labeling acurracy | ±5-10mm | |

Data transmission | USB data export | |

| Optional function | Real-time printing, barcode reading and sorting, online inkjet printing, online barcode reading, online labeling | |

Available Rejection Systems for Weighing and Labeling Machine SCL-8050L30

The heavy-duty pusher rejector pair with checkweigher systems to deliver accurate, mid-speed removal of heavy, boxed items.

Fast swing arm works with checkweigher or metal detector systems to remove defective boxes and bags up to 1 kg.

Up and Out Rejector for checkweigher and metal detector systems — stable, gentle, and precise for soft or thick products.

Samegram’s Belt Drop rejector is a high speed rejector using pneumatic lift rods to gently remove thin bags and flat products.

* The maximum checkweighing speed and accuracy may vary depending on the actual product being tested and the installation environment.

* When selecting the model, pay attention to the direction of product movement on the conveyor belt. For transparent or semi-transparent products, please contact our company.

* When selecting the model, pay attention to the direction of product movement on the conveyor belt. For transparent or semi-transparent products, please contact our company.

File Downloads

For more product related parameter files, please contact us.