What Is a Checkweigher? Enhance Food Safety with Washdown Checkweigher

- Share

- Issue Time

- Jul 29,2025

Summary

Discover what a checkweigher is and how washdown models boost food safety, ensure regulatory compliance like HACCP and FSMA, and improve efficiency in food manufacturing. Explore SameGram's durable, precision checkweighers for reliable solutions and reduced recalls today.

In the demanding world of food manufacturing, ensuring product safety, accurate weights, and regulatory compliance is essential. If you're wondering, "What is a checkweigher?" or "How can a washdown checkweigher improve my operations?"—you're in the right place. A checkweigher is a precision weighing system that verifies product weights on production lines, preventing under- or over-filling while maintaining hygiene standards.

Washdown checkweighers, in particular, are built for harsh, wet environments, making them ideal for food processing. They help comply with regulations like HACCP and FSMA, reduce recalls, and boost efficiency. In this guide, we'll explore their benefits, features, and why SameGram leads the market. Discover our full range of checkweighers on our product page.

Understanding Washdown Checkweighers: Key Features and Functions

Checkweighers are automated scales integrated into conveyor systems, weighing products in motion. Washdown models add water-resistant designs for easy cleaning, crucial in food safety.

Why Choose a Washdown Checkweigher?

Standard checkweighers work well in dry settings, but food production demands more. Washdown checkweighers withstand high-pressure cleaning, preventing contamination and supporting GMP.

Hygienic Design for Superior Food Safety

Built with food-grade stainless steel (304 or 316L), these checkweighers feature smooth surfaces, no crevices, and sloped designs for drainage. This minimizes bacterial growth and allergen risks, aligning with HACCP principles.

Durability in Harsh Environments: IP Ratings Explained

With IP65, IP67, or IP69K ratings, washdown checkweighers resist dust, water, and high-temperature jets—perfect for dairy, meat, or poultry processing.

SameGram’s Durable Checkweigher Solutions

At SameGram, our checkweighers offer top IP ratings and long-lasting performance. Explore our rugged options here.

How Checkweighers Ensure Regulatory Compliance and Weight Accuracy

Accurate weights are non-negotiable for compliance. Checkweighers monitor every item, ensuring labels match contents within tolerances.

Avoiding Fines and Waste: The Compliance Advantage

Under-filling leads to penalties; over-filling wastes profits. Real-time feedback from checkweighers adjusts filling processes, keeping you compliant and efficient.

Integration with HACCP: Checkweighers as Critical Control Points

HACCP demands proactive hazard prevention, and washdown checkweighers shine as Critical Control Points (CCPs) for weight accuracy. They monitor weights in real time, triggering instant corrections if limits are breached. This reduces the risk of unsafe products reaching consumers.

Real-World Demonstration: Checkweigher Sorting Fresh Foods

Watch our video to see a SameGram checkweigher in action, precisely weighing and sorting fresh produce.

Preventing Recalls and Boosting Brand Protection

Weight errors or contamination trigger recalls, costing millions. Washdown checkweighers mitigate this by ensuring accuracy and hygiene.

Visit our profile page to see how SameGram helps safeguard brands.

Enhancing Efficiency: Automation and Traceability

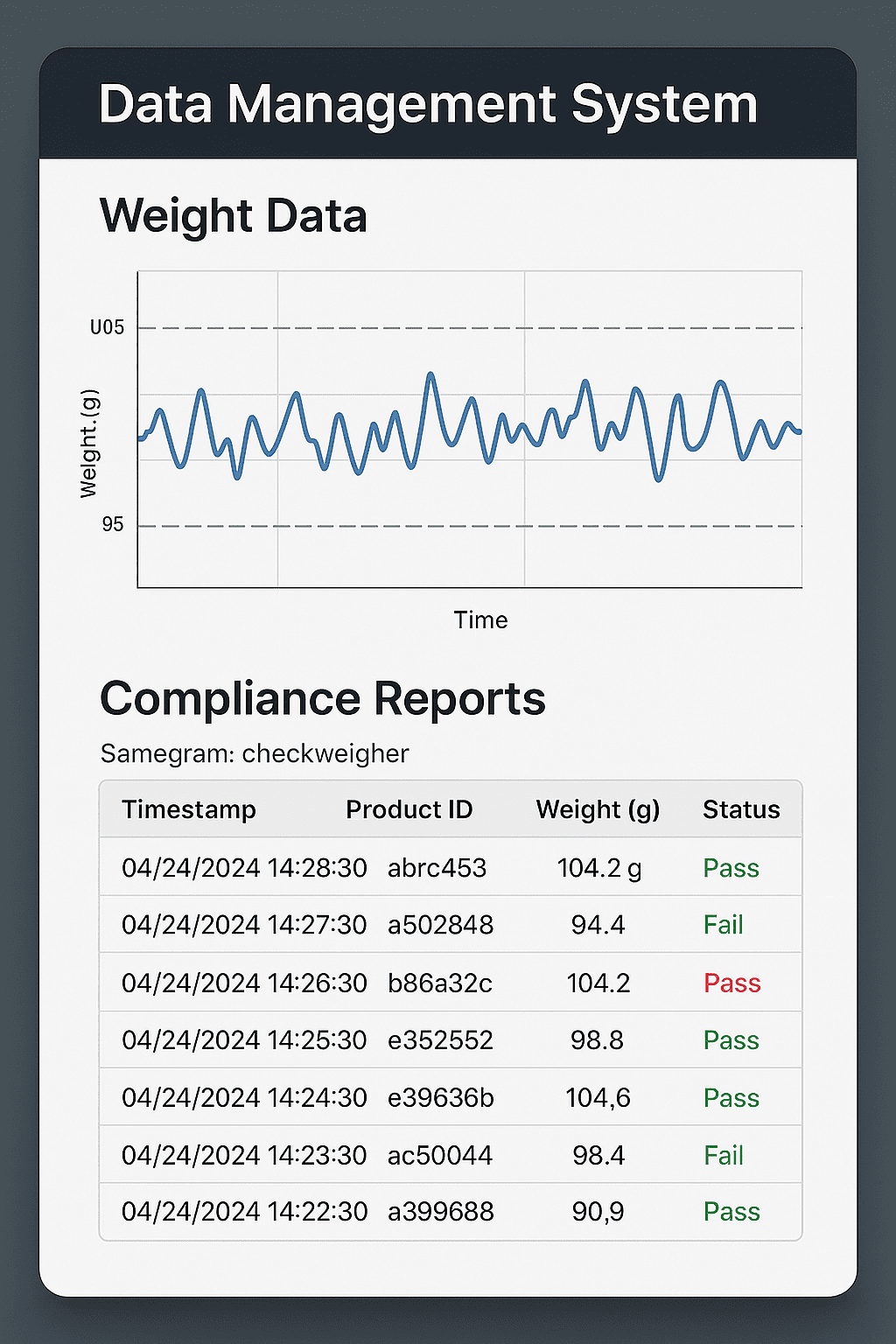

Checkweighers don’t just ensure compliance—they enhance efficiency. Automation eliminates manual errors, speeds up production, and cuts labor costs. SameGram’s systems include feedback loops to adjust filling equipment in real time, reducing waste and optimizing throughput.

Smart Tech for the Future

SameGram leads with smart checkweighers featuring IoT for predictive maintenance, advanced sensors, and AI analytics—tools that elevate both compliance and performance.

Future-Proofing with Smart Technology

SameGram’s IoT-enabled checkweighers offer predictive maintenance and AI analytics for proactive operations.

Traceability and Data: Compliance Made Simple

Traceability is a regulatory must. Washdown checkweighers integrate with data systems, logging weight details for audits, quality checks, and recall readiness. Digital records beat manual methods every time, as noted by the FDA’s FSMA guidelines.

Checkweigher Benefits at a Glance

| Feature | Food Safety & Compliance Benefit | Operational Benefit | ||

Hygienic Design | Prevents contamination | Cuts cleaning time | ||

Weight Accuracy | Ensures compliance, avoids fines | Reduces giveaway | ||

| Washdown Capability | Meets HACCP/GMP standards | Lowers recall risk | ||

Real-time Data | Enables fast CCP corrections | Optimizes filling | ||

| Robust Construction | Reliable in harsh settings | Minimizes downtime | ||

| Integration | Enhances traceability | Streamlines data management | ||

Frequently Asked Questions About Checkweighers

What is a checkweigher used for?

A checkweigher verifies product weights to ensure compliance and prevent waste.

How does a washdown checkweigher differ from a standard one?

Washdown models are water-resistant for easy sanitation in food environments.

Why is IP rating important in checkweighers?

It indicates protection against water and dust, ensuring durability during cleaning.

Conclusion: Elevate Your Operations with SameGram Checkweighers

Washdown checkweighers are vital for food safety, compliance, and efficiency. SameGram provides reliable, innovative solutions tailored to your needs. Contact us or browse our products today!

Related Hot-sale Checkweighers

SCP6 is a dynamic checkweighing system for small packages. it supports multi-lane control, fast data export and GMP compliance.

WSS-5012L2 is a compact weight sorter machine designed to ensure stable output and quality control. ideal for fish and meat.

SWSR-750TC6 is a stainless steel weight sorting machine designed for food use,very suitable for fish ,seafood and poulty

SBW-2512B12 is a multi head combination weigher ideal for fast, precise dosing,also known as linear combination scale.

SC1-H-3512L1 is a high accuracy checkweigher designed for production line with high precision requirements like pharmaceuticals