Precision Checkweigher for the Printing Industry | Samegram

- Share

- Issue Time

- Jul 21,2025

Summary

Discover how Samegram's checkweigher boosts printing quality and streamlines production. Explore its precision design, seamless integration, and tailored features for the printing industry.

Introduction to Checkweighing in the Printing Industry

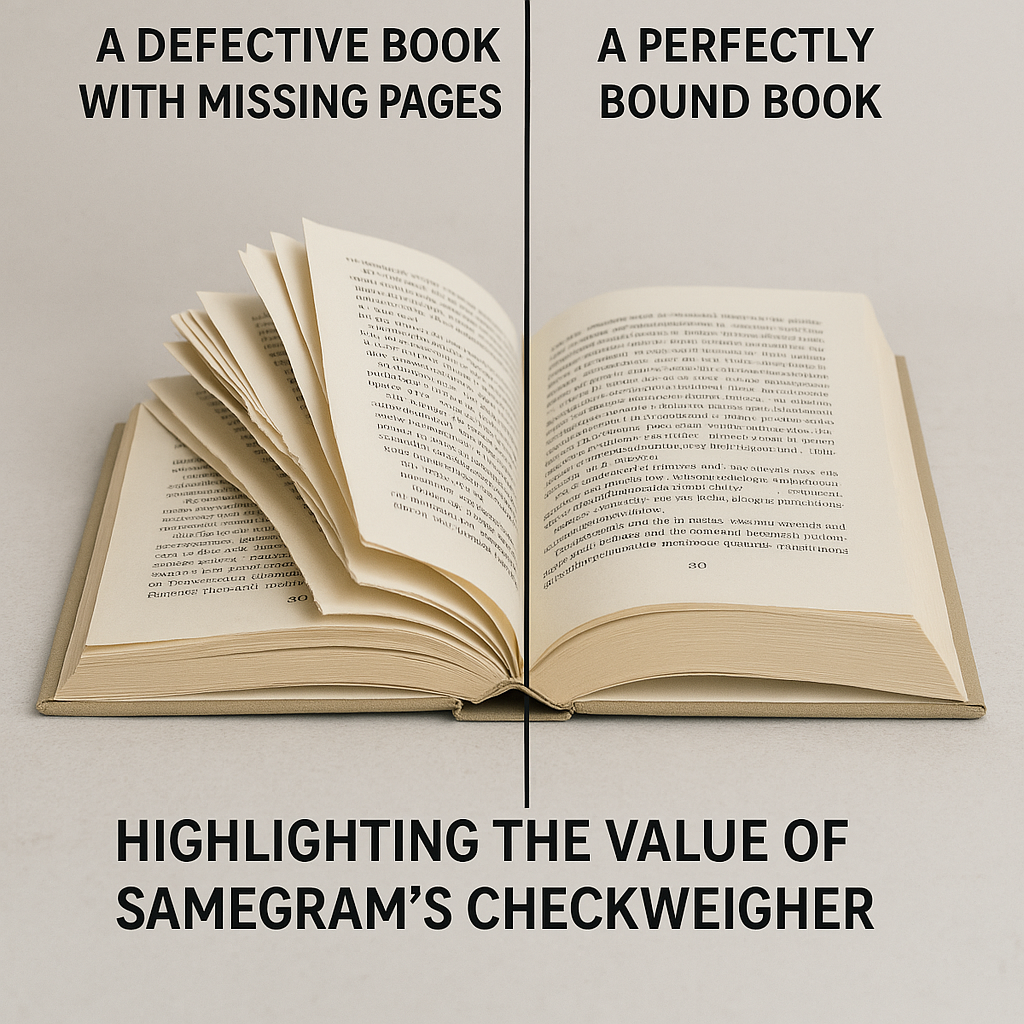

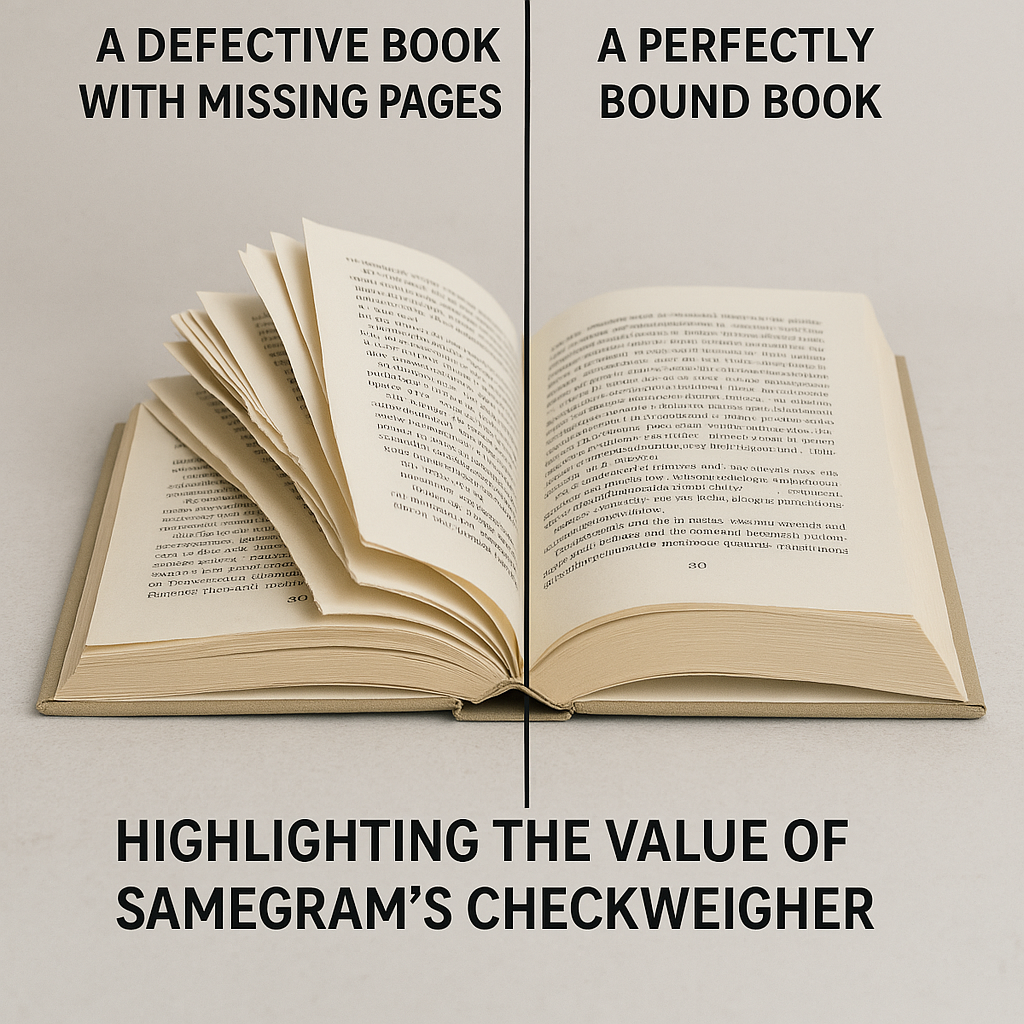

In the printing industry, precision is everything—especially when producing books made from thin, delicate paper. A single missing or extra page can lead to costly reprints, wasted materials, and dissatisfied customers. That’s where a checkweigher comes in. Samegram, a trusted leader in checkweighing technology, offers an advanced checkweigher system designed specifically for the printing industry. Our solution ensures every book meets your exact quality standards, enhancing efficiency and protecting your reputation.

Why Choose Samegram's Checkweigher?

Unmatched Precision with Cutting-Edge Technology

Samegram’s checkweigher leverages high-precision sensors and advanced data processing to deliver fast, accurate weight detection. Whether a book has too many or too few pages, our system identifies discrepancies instantly, allowing for timely corrections. Built to handle the unique challenges of thin paper, this checkweigher ensures reliability without compromising product integrity.

Seamless Production Line Integration

Our dynamic checkweigher fits effortlessly into your printing production line. Books are placed on the scale plate, and real-time weighing begins immediately. The system transmits weight data to the control unit, compares it to preset standards, and flags any deviations. Non-conforming books are automatically removed via a sliding or conveying device, maintaining uninterrupted production flow.

Real-Time Feedback for Total Control

With Samegram’s checkweigher, you’re always in the know. Every detection and removal is logged, and operators receive real-time feedback through an intuitive display or alarm system. This allows for quick responses to any issues, reducing downtime and ensuring consistent quality.

How Samegram’s Checkweigher Works

1. Weighing Initiation: Books are placed on the scale plate, triggering immediate real-time weighing.

2. Data Processing: Weight data is sent to the control system and compared against preset standards.

3. Deviation Detection: Any weight variation flags the book as non-conforming.

4. Automated Removal: Non-compliant books are smoothly removed from the line, preserving production continuity.

5. Monitoring and Alerts: All operations are recorded, with real-time feedback provided via display or alarms.

This efficient process minimizes errors and maximizes productivity, making Samegram’s checkweigher a must-have for modern printing operations.

Key Features of Samegram's Checkweigher

High-Precision Detection

Calibrated for the smallest weight differences, our checkweigher excels at detecting issues in thin-paper books, ensuring every product meets your specifications.

Flexible Expansion Options

Equipped with RS232/485 and Ethernet ports, Samegram’s checkweigher integrates seamlessly with ERP and MES systems, providing valuable data for production optimization.

Tailored Customization

Every printing operation is unique. Samegram offers customizable checkweigher solutions to match your specific production and management needs.

The Critical Role of Checkweighers in Printing

Producing books with thin paper presents challenges like misfeeds or double feeds during binding, resulting in incorrect page counts. Manual inspections are time-consuming and prone to error. Samegram’s checkweigher automates quality control, catching mistakes early to reduce waste and improve efficiency.

Why Samegram Leads in Checkweighing Solutions

Samegram is a trusted name in precision checkweighing, delivering innovative and reliable solutions to the printing industry worldwide. Our expertise ensures:

● Superior Quality: Every book meets rigorous standards.

● Increased Efficiency: Automated checks speed up production.

● Cost Savings: Early error detection reduces waste.

● Actionable Insights: Real-time data optimizes your processes.

Elevate Your Printing Operations with Samegram

Ready to enhance your production line with a top-tier checkweigher? Samegram’s experts are here to provide a tailored solution that meets your needs.

Contact Us Today to explore how our checkweigher can revolutionize your quality control.

Related Hot-sale Checkweigher

The SC1-C-3523L1 is the most suitable checkweigher for small packages. It has positive and negative weight selection functions and is compact and economical.

SC1-5040L5 is an economy and hi speed dynamic checkweigher ideal for in line weight checking with precision and reliability.

SC-C is a checkweigher designed for cans ,jars and bottles,which is a reliable online checkweigher machine for production line.

SCL-10060L50 is an automatic weigh price labeler with scanning, weighing scale label printing, and template customization.

SCL-8050L30 is an advanced automatic price weigh label machine with dynamic weighing, label editing, and MES/ERP integration.