Inline Checkweigher for Cans and Bottles SC-C

- Model

- SC-C-4530L3

Item specifics

- Weighting section size

- Non-standard customization

- Belt speed

- 5-90m/min

- Applicable product size

- Non-standard customization

- Rejection mode

- Customized

- Storage formula

- 100 types

Review

Description

Detail Information

Inline Checkweigher for Cans and Bottles SC-C-4530L3

Introduction

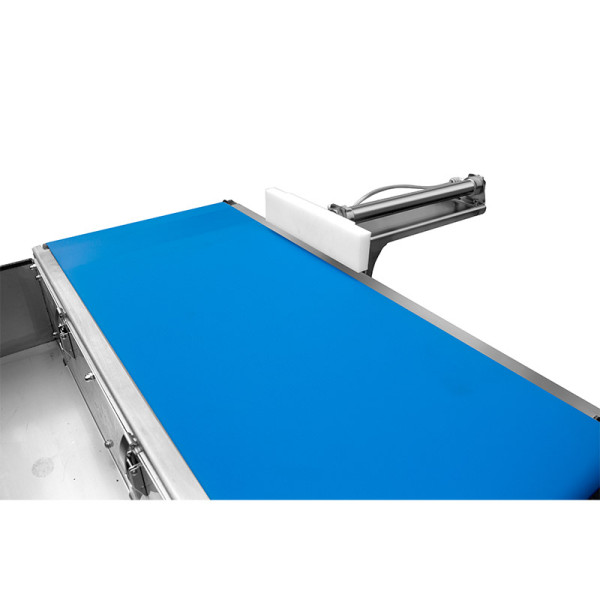

The SC-C-4530L3 is a high-precision inline checkweigher designed for high-speed production lines handling cans, bottles, and jars. Equipped with adjustable bottle clamps, it ensures stable product transport, preventing tipping or damage during conveyance.

The system automatically spaces products for real-time weight inspection, accurately identifying underfilled or overweight items. With fully integrated reject mechanisms, this automatic checkweigher helps maintain consistent quality and compliance.

Compact and robust, the SC-C functions as both a can checkweigher and bottle checkweigher, easily integrating into existing lines to improve efficiency while supporting reliable checkweighing system operations for fast-moving containers.

Inline Checkweigher for Cans and Bottles SC-C-4530L3 Features

Inline Checkweigher for Cans and Bottles SC-C-4530L3 Technical Parameters

| Product model | SC-C-4530L3 | |

| Weighting range | 1-3000g | |

Weighting section size | L 450mm*W 300mm | |

Belt speed | 5-90m/min | |

Air pressure interface | Φ8mm | |

| Case material | 304 stainless steel | |

Conveying direction | Facing the machine, left in and right out | |

Display division | 0.1g | |

| Weighting accuracy | ±0.5-±2g | |

| Applicable product size | L≤350mm; W≤280mm | |

Storage formula | 100 types | |

| Power supply | AC220V±10% | |

| Air source | 0.5-0.8MPa | |

Data transmission | USB data export | |

Alarm mode | Sound and light alarm and automatic rejection | |

Rejection mode | Air blowing, push rod, swing arm, drop, up and down flip, etc. (customizable) | |

| Optional function | Real-time printing, code reading and sorting, online code spraying, online code reading, online labeling | |

Operation screen | 10-inch Weiluntong color touch screen | |

Control system | Samegram online weighing control system V1.0.5 | |

| Other configurations | Meanwell power supply, Jingyan motor, Swiss PU food conveyor belt, NSK bearing, Mettler Toledo sensor | |

* The maximum checkweighing speed and accuracy may vary depending on the actual product being tested and the installation environment.

* When selecting the model, pay attention to the direction of product movement on the conveyor belt. For transparent or semi-transparent products, please contact our company.

* When selecting the model, pay attention to the direction of product movement on the conveyor belt. For transparent or semi-transparent products, please contact our company.

Title

Fast swing arm works with checkweigher or metal detector systems to remove defective boxes and bags up to 1 kg.

The heavy-duty pusher rejector pair with checkweigher systems to deliver accurate, mid-speed removal of heavy, boxed items.

File Downloads

For more product related parameter files, please contact us.