High-Precision Checkweigher for Hardware Packaging | Samegram Solutions

- Share

- Issue Time

- Jul 26,2025

Summary

Discover how Samegram's advanced checkweigher ensures accurate hardware packaging with high-speed weighing and automatic rejection. Boost efficiency, reduce waste, and meet compliance standards with our innovative solutions. Contact us today!

In the fast-paced world of hardware manufacturing, ensuring each package contains the correct number of components is critical for maintaining product quality, regulatory compliance, and customer satisfaction. Samegram, a leading innovator in industrial automation solutions, provides a state-of-the-art Checkweigher system designed to enhance production efficiency and quality control on hardware packaging lines. This case study explores how Samegram's high-precision belt weighing machine, equipped with an advanced air-blowing rejection system, transforms hardware packaging processes by ensuring accuracy, reducing waste, and boosting operational efficiency.

The Challenge: Ensuring Precision in Hardware Packaging

Hardware products, such as screws, bolts, and small components, are often packaged in large volumes, where even minor errors in quantity can lead to significant customer dissatisfaction or costly recalls. Manual inspection is labor-intensive, prone to human error, and inefficient for high-speed production lines. Additionally, regulatory standards in industries like electronics, automotive, and construction demand strict adherence to weight specifications to ensure compliance. To address these challenges, manufacturers require a reliable, automated solution that guarantees precision, minimizes waste, and maintains high throughput.

Samegram's in-motion checkweigher solution, developed by Guangdong SameGram Intelligent Equipment Co., Ltd., is engineered to meet these demands. With a commitment to innovation and quality, Samegram leverages advanced weighing technology to deliver unparalleled accuracy and efficiency for hardware packaging lines.

Samegram’s High-Precision Checkweigher Solution

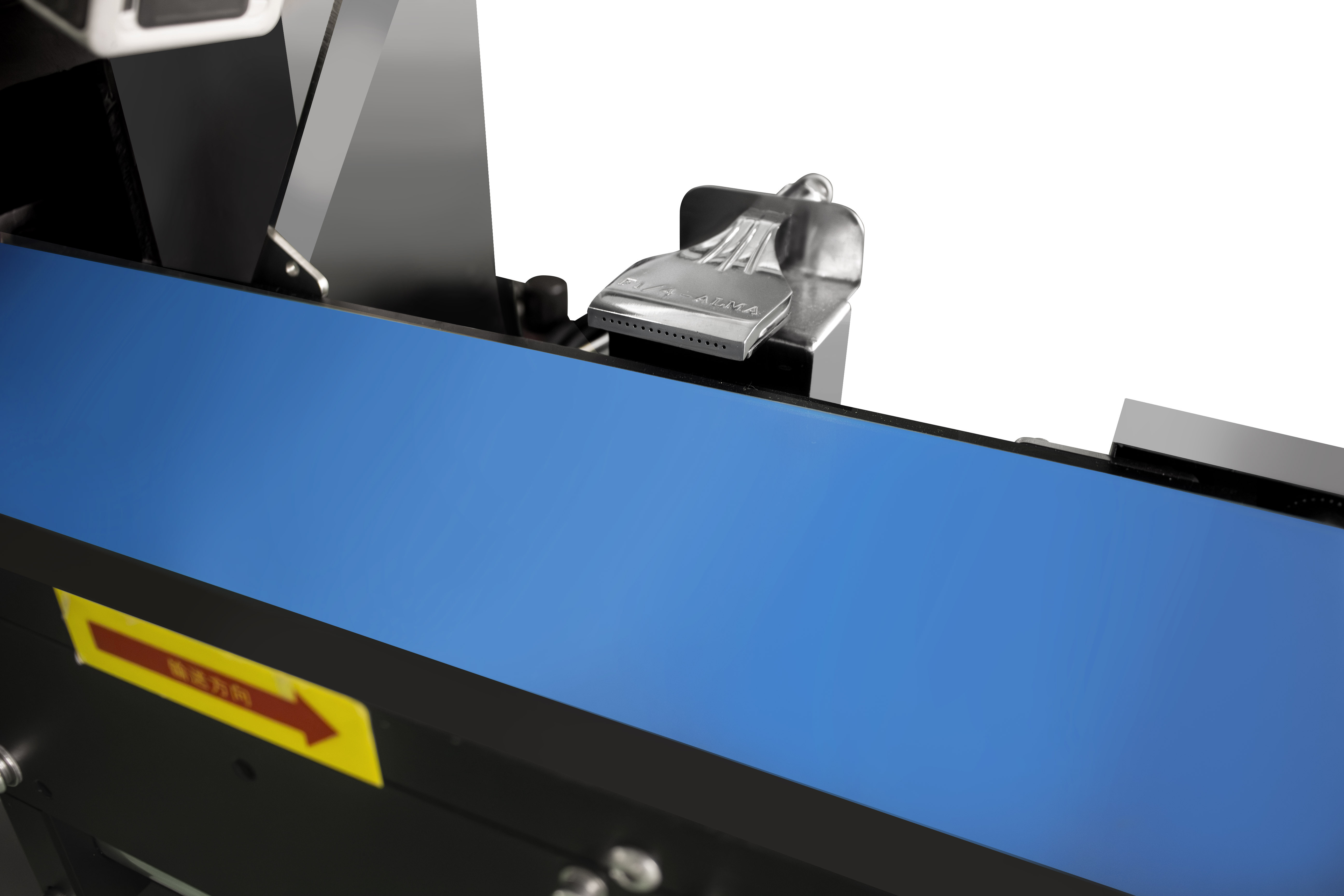

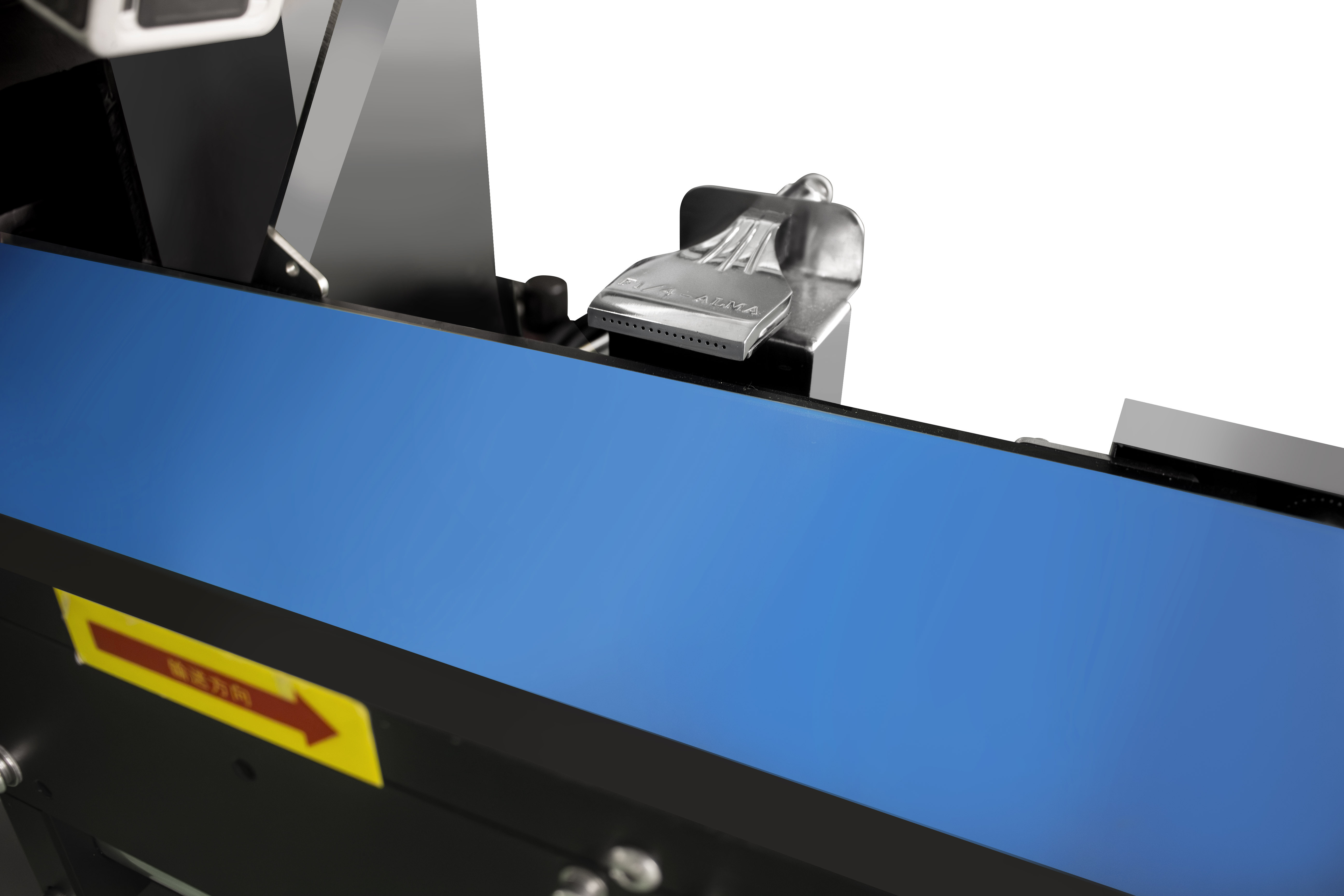

Samegram's motion checkweigher is a cutting-edge, dynamic weighing system designed to integrate seamlessly into high-speed hardware packaging lines. Featuring a robust stainless steel construction and precision load cells, this system ensures accurate weight measurements even at conveyor speeds exceeding 300 feet per minute. The automatic checkweigher machine is equipped with an advanced pneumatic Reject System, which automatically removes underfilled or overweight packages, ensuring only compliant products proceed to the next stage of production.

How It Works

1. Weighing Process: Hardware packages enter the weighing area via a high-speed conveyor belt. The checkweigher equipment uses load cells to measure the weight of each package with an accuracy of ±0.1g, ensuring precise detection of underfilled or overfilled packages.

2. Data Analysis: The system's intelligent control unit compares the measured weight against preset target weight ranges. If the package weight falls within the acceptable range, it is deemed compliant and proceeds along the production line.

3. Automatic Rejection: If a package is underweight (indicating missing components) or overweight, the control system triggers the airblast rejection mechanism. High-pressure air jets swiftly divert non-compliant packages to a designated collection area, preventing defective products from reaching consumers.

4. Data Traceability: Samegram's checkweigher machines feature advanced data logging capabilities, storing up to 30,000 weight records and supporting integration with factory ERP and MES systems for real-time production insights. This ensures traceability and facilitates compliance with quality control standards.

Benefits of Samegram's Checkweigher Machines for Hardware Packaging

Enhanced Production Efficiency

Samegram's online checkweigher machine supports high-throughput environments, inspecting up to 330 products per minute. Its compact, multi-column design saves valuable production floor space while integrating seamlessly with existing packaging equipment, such as sealing machines and palletizers. By automating weight checks, manufacturers can reduce labor costs and eliminate manual errors, boosting overall productivity.

Superior Quality Control

The high-precision load cells ensure accurate weight measurements, detecting even minor deviations that could indicate missing or extra components. This is critical for hardware manufacturers, where consistency is paramount to meeting customer expectations and regulatory requirements. The system's ability to reject non-compliant packages in real-time minimizes the risk of defective products reaching the market, protecting brand reputation and avoiding costly recalls.

Regulatory Compliance

In industries like electronics and automotive, adherence to strict weight and packaging regulations is non-negotiable. Samegram’s checkweigher machine ensures compliance with global standards, such as Weights & Measures requirements, by providing precise weight verification and comprehensive data reporting. This helps manufacturers avoid fines and maintain consumer trust.

Reduced Waste and Cost Savings

By identifying and rejecting underfilled or overweight packages early in the production process, Samegram’s Checkweigher minimizes product giveaway and reduces material waste. This not only lowers production costs but also supports sustainable manufacturing practices by optimizing resource use.

Seamless Integration and User-Friendly Design

Designed for versatility, Samegram's Checkweigher can handle a wide range of package sizes, from small hardware components to large 50kg packages. Its user-friendly LCD touchscreen interface supports multi-language options (defaulting to Chinese and English) and stores up to 100 product presets for quick changeovers. The system's modular design allows for easy maintenance and integration with other quality control equipment, such as metal detectors or labeling machines.

Why Choose Samegram?

As a high-tech enterprise specializing in automatic packaging and testing equipment, Samegram (Guangdong SameGram Intelligent Equipment Co., Ltd.) combines cutting-edge technology with a customer-centric approach. With a dedicated design team and a global presence in markets across Asia, North America, Europe, and Africa, Samegram delivers tailored solutions that meet the unique needs of hardware manufacturers. Our Checkweigher systems are built with premium components, including German Schneider switches, Swiss HABASIT conveyor belts, and Japanese OMRON relays, ensuring reliability and durability in demanding production environments.

Samegram's commitment to quality is backed by rigorous testing and calibration, ensuring our Checkweighers deliver stable performance with minimal maintenance. Our systems are trusted across industries, including electronics, pharmaceuticals, and food, for their precision, efficiency, and compliance with international standards. For more information about our products, visit Samegram's product page

Conclusion

Samegram's high-precision Checkweigher is a game-changer for hardware packaging lines, offering unmatched accuracy, efficiency, and compliance. By automating weight verification and rejection processes, this system ensures consistent product quality, reduces waste, and enhances customer satisfaction. With advanced data traceability and seamless integration capabilities, Samegram empowers manufacturers to optimize their production processes while meeting stringent regulatory requirements.

Ready to elevate your hardware packaging line? Contact Samegram today to learn how our Checkweigher solutions can transform your operations.

Related Hot-sale Checkweigher

SC-C is a checkweigher designed for cans ,jars and bottles,which is a reliable online checkweigher machine for production line.

SC2-8050L30 is a high-capacity dynamic checkweigher for packages up to 30 kg. This machine is very economical and widely used.

SC3-10070L80 is a heavy duty checkweigher ideal for large items up to 80 kg. This machine is also known as roller checkweigher.

SC3-L-12080S60 is one of the best parcel weighing scales for large-items up to 60kg.,which can be integrated into DWS system.

The SC2-L-6055S5 is a logistics scale for parcel weighing under 5kg . Designed for fast, accurate weighing out logistics,