Dynamic Checkweigher for Inline Checkweighing Systems SC3-8050L30

- Model

- SC3-8050L30

Item specifics

- Weighting range

- 0.05-30kg

- Belt speed

- 5-90m/min

- Weighting accuracy

- ±3-10g

- Weighting section size

- L 800mm*W 500mm

- Applicable product size

- L≤600mm;W≤500mm

- Rejection mode

- Customized

Review

Description

Detail Information

Dynamic Checkweigher for Inline Checkweighing Systems SC3-8050L30

Introduction

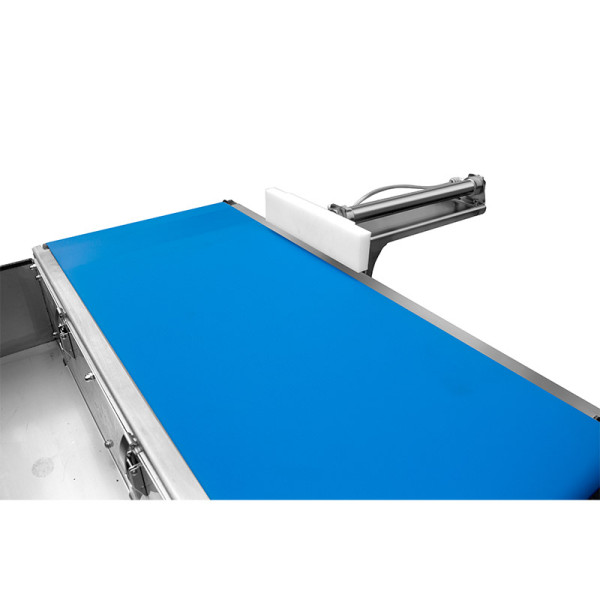

The auto checkweigher machine SC3-8050L30 is a high-capacity dynamic checkweigher designed for inline quality control of large packages up to 30kg, such as cartons of instant noodles, snacks, or bottled water. Constructed from 304 stainless steel with IP65 protection, it is built to withstand demanding industrial environments.

This in-motion checkweigher integrates seamlessly with automated assembly lines, filling machines, and vertical packaging systems, enabling precise inline checkweighing without interrupting production flow. Its intelligent auto checkweigher machine function automatically detects under- or overweight items, improving efficiency and reducing manual error.

Part of our advanced dynamic checkweigher systems, the SC3-8050L30 delivers consistent, reliable performance across high-speed packaging lines, ensuring compliance, accuracy, and operational stability for industrial and logistics applications.

Dynamic Checkweigher for Inline Checkweighing Systems SC3-8050L30 Features

Dynamic Checkweigher for Inline Checkweighing Systems SC3-8050L30 Technical Parameters

| Product model | SCW8050L30 | |

| Weighting range | 0.05-30kg | |

Weighting section size | L 800mm*W 500mm | |

Belt speed | 5-90m/min | |

Air pressure interface | Φ8mm | |

| Case material | 304 stainless steel | |

Conveying direction | Facing the machine, left in and right out | |

Display division | 1g | |

| Weighting accuracy | ±3-10g | |

| Applicable product size | L≤600mm;W≤500mm | |

Storage formula | 100 types | |

| Power supply | AC220V±10% | |

| Air source | 0.5-0.8MPa | |

Data transmission | USB data export | |

Alarm mode | Sound and light alarm and automatic rejection | |

Rejection mode | Air blowing, push rod, swing arm, drop, up and down flip, etc. (customizable) | |

| Optional function | Real-time printing, code reading and sorting, online code spraying, online code reading, online labeling | |

Operation screen | 10-inch Weiluntong color touch screen | |

Control system | Samegram online weighing control system V1.0.5 | |

| Other configurations | Meanwell power supply, Jingyan motor, PVC food conveyor belt, NSK bearing, | |

* The maximum checkweighing speed and accuracy may vary depending on the actual product being tested and the installation environment.

* When selecting the model, pay attention to the direction of product movement on the conveyor belt. For transparent or semi-transparent products, please contact our company.

* When selecting the model, pay attention to the direction of product movement on the conveyor belt. For transparent or semi-transparent products, please contact our company.

Available Rejection Systems for Inline Checkweighing Systems SC3-8050L30

The heavy-duty pusher rejector pair with checkweigher systems to deliver accurate, mid-speed removal of heavy, boxed items.

Fast swing arm works with checkweigher or metal detector systems to remove defective boxes and bags up to 1 kg.

File Downloads

For more product related parameter files, please contact us.

Dynamic Checkweigher for Inline Checkweighing Systems Applications

The dynamic checkweigher SC3-8050L30 is specially built for large-package inspection, but different industries pack different types of contents inside these big boxes. To ensure customers instantly relate to their own industry, we highlight several representative sectors below—using the full industry terms exactly as you require, while naturally expanding the scenarios.

Large cartons containing bottles, blister boxes, bulk packs, or mixed SKUs require accurate final weight verification before palletizing. The checkweigher detects missing inner boxes, leaflet shortages, or packaging errors, ensuring compliance and batch integrity for regulated

Shampoos, lotions, creams, and cosmetic sets are often shipped in heavy multi-unit cartons. The auto checkweigher machine SC3-8050L30 prevents underfilled or mismatched cartons, reducing customer complaints and avoiding costly reverse logistics.

This model handles bulk cartons containing yogurt trays, UHT milk packs, butter blocks, and egg cartons. It verifies total load integrity, ensuring no product loss during upstream filling and packing operations.

Cartons packed with assorted pastry boxes, snack bags, or multilayer cardboard trays benefit from accurate final weight checks to prevent missing packs or count errors—especially in export shipments.

For chemical powders, fertilizers, water-treatment additives, or household chemical products packed in large corrugated boxes, the system ensures each carton meets regulatory weight requirements and prevents leakage-related shortages.

Third-party logistics centers use the SC3-8050L30 to confirm carton weight before labeling, sorting, or route allocation. Accurate weight improves freight billing accuracy and reduces misrouting.

These targeted industry examples help customers recognize real use cases and build trust that the in motion checkweigher SC3-8050L30 is proven across multiple sectors.

Dynamic Checkweigher for Inline Checkweighing Systems Applications

Why Choose the Auto Checkweigher Machine SC3-8050L30 From SameGram?

Industry-proven across multiple sectors

SC3‑8050L30 has been successfully used in pharmaceuticals, FMCG, dairy, cosmetics, chemicals, and logistics. Its stability and accuracy have been validated in high-volume industrial environments.

Designed for Heavy and Large Packages

Built for products up to 30 kg, with reinforced frames, high-capacity sensors, and wide conveyor belts, ensuring precise measurement even for large cartons and heavy items.

Advanced Dynamic Algorithms

High-speed data acquisition, vibration compensation, and adaptive zero-point adjustments allow accurate weighing in fast-moving production lines, reducing errors and waste.

Modular and Scalable Design

Supports various ejection modules, adjustable conveyor size/speed, and integration with PLC, MES, or labeling systems. Easily adaptable for future line upgrades or automation.

Reliable After-Sales Support

Includes detailed manuals, on-site guidance, remote troubleshooting, and system monitoring. Ensures minimal downtime and consistent operation over time.

In Motion Checkweighers Technology & Performance Overview

Reinforced Structure for Heavy-Duty Stability

A purpose-built mechanical frame, oversized conveyor platform, and high-capacity load cell deliver stable weighing performance for large and heavy cartons, minimizing vibration interference during continuous operation.

Advanced Dynamic Weighing Algorithms

Multi-stage digital filtering, vibration suppression, and adaptive compensation algorithms ensure accurate results on fast-moving lines, even when product spacing or orientation varies.

Intelligent Auto-Learning & Self-Calibration

Built-in auto-learning optimizes thresholds, filtering coefficients, and compensation values, while easy zero and span calibration help maintain long-term weighing accuracy with minimal operator input.

Modular Control & Motor Management

Supports analog voltage and RS485 Modbus motor control, customizable frequency registers, and multi-zone speed coordination, enabling precise conveyor synchronization across complex production lines.

Flexible Photoelectric & I/O Logic Configuration

Multiple photoelectric modes (dual-sensor, in/out detection, no-sensor mode) and customizable I/O mapping allow seamless integration with upstream packaging machines, labeling units, rejecters, and factory automation systems.

Real-Time Diagnostics & Performance Monitoring

On-screen status indicators, I/O testing tools, and built-in alarm logic provide instant feedback on errors, sensor conditions, motor status, and data overflow—ensuring consistent uptime and fast troubleshooting.

Dynamic Checkweigher for Inline Checkweighing Systems Installation & Integration Recommendations

To achieve optimal weighing precision for large cartons:

Ensure Structural Stability

Install the checkweigher:

·Away from vibration sources (pallet wrappers, chain conveyors, motors)

·On a leveled floor

·With locking feet properly adjusted

Maintain Straight, Stable Product Transfer

Minimize impacts between conveyors:

·Align upstream and downstream conveyors at identical height

·Keep transition gaps small

·Avoid carton collisions or compression from upstream machines

Configure Photoelectric Sensors Correctly

Accurate trigger timing is essential for dynamic weighing. Use:

·Dual-sensor mode for long cartons

·In-sensor mode for synchronized feeding

·Adjustable brackets for precise beam alignment

Perform Load Cell Calibration Periodically

Use certified test weights:

·Zero calibration (empty conveyor)

·Span calibration (known load)

·Dynamic compensation tuning for real production conditions

Protect Electrical Components

Avoid washing electrical cabinets directly with water. Maintain clean, dry conditions to extend system lifespan.

Dynamic Checkweigher for Inline Checkweighing Systems FAQs

Q1: What is the typical weighing accuracy and speed?

A: Accuracy depends on product shape, speed, and conveyor stability. For standard applications, accuracy ranges from ±0.5g to ±3g.

Q2: Can the SC3-8050L30 be integrated with a barcode scanner or label printer?

A: Yes. Dealers commonly combine this checkweigher with scanners and labelers in DWS systems.

Q3: Is recipe switching easy for multi-product lines?

A: The system supports 20 recipes, each with configurable name, unit, speed, and thresholds.

Q4: Can I export historical data?

A: Yes. Data can be exported to USB by selecting the date range.

Q5: Does the system support Modbus communication?

A: Yes, RS485 Modbus RTU is supported for motor control and system integration.