Boost Pharmaceutical Efficiency with Samegram’s Precision Checkweigher

- Share

- Issue Time

- Jul 23,2025

Summary

Discover how Samegram's automated checkweigher for boxed medicine ensures precision, quality, and efficiency in pharmaceutical production lines. Learn about its features, benefits, and real-world applications.

Introduction: The Critical Role of In-motion Checkweighers in Pharmaceutical Production

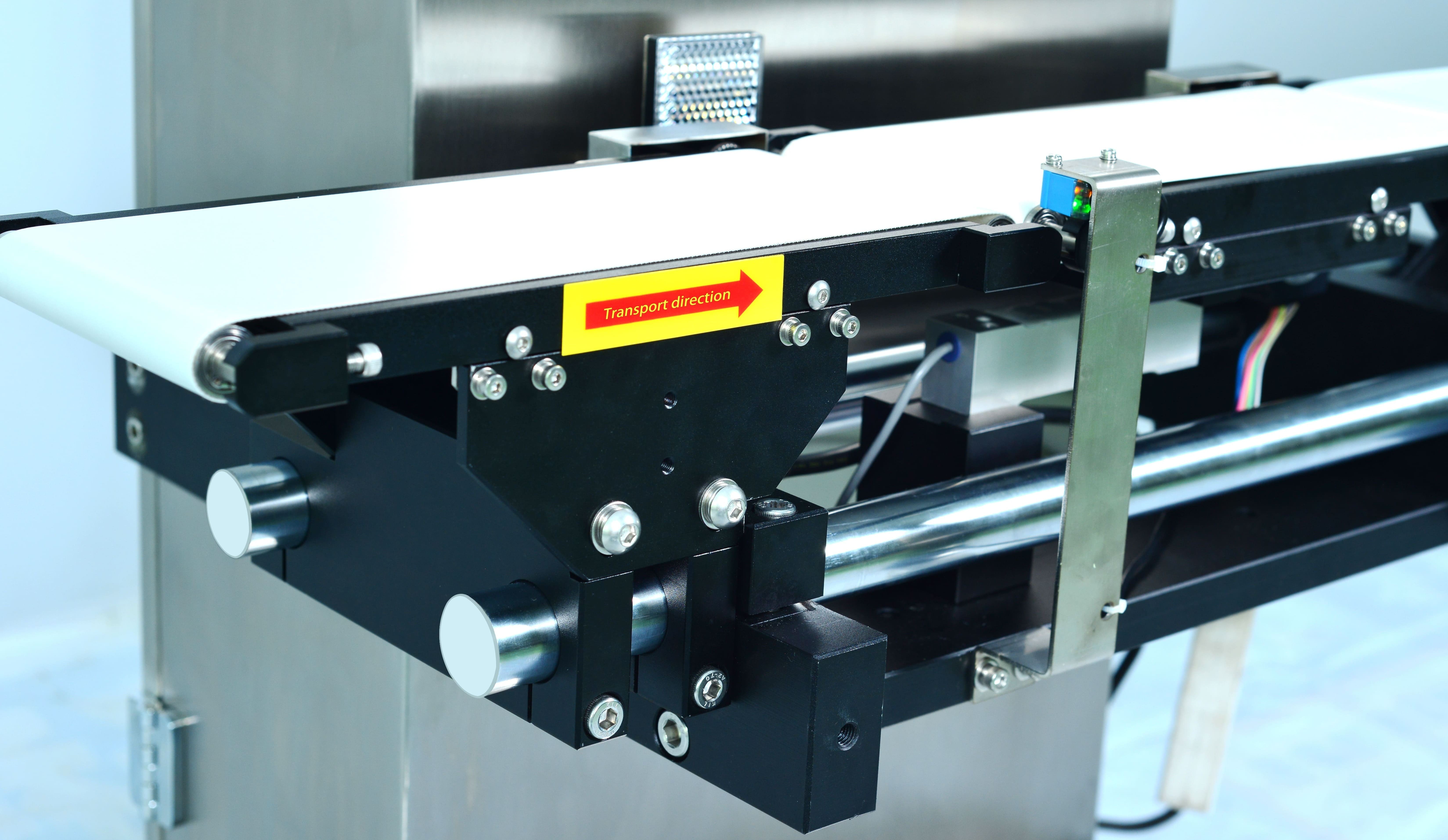

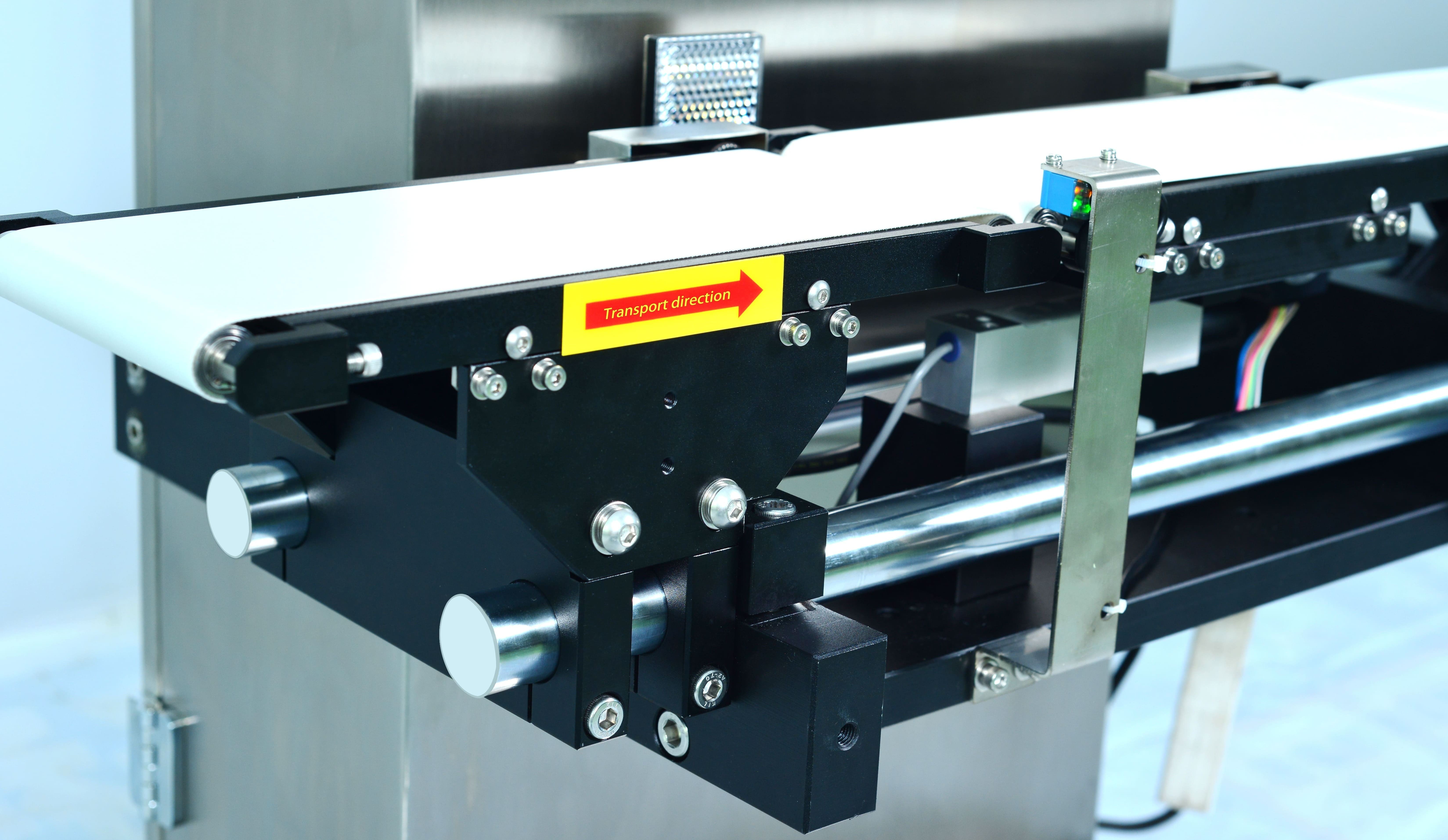

In the fast-paced world of pharmaceutical manufacturing, precision is non-negotiable. Every boxed medicine must meet stringent weight standards to ensure patient safety, regulatory compliance, and product consistency. This is where a checkweigher system becomes a vital tool. A checkweigher is an advanced device that automatically verifies the weight of products on a production line, ensuring they align with predefined specifications. For pharmaceutical companies handling small square packages or thick, long strip packages, a reliable dynamic checkweigher is essential to maintain quality and efficiency.

Samegram, a trusted name in industrial automation, offers its cutting-edge boxed medicine automatic checkweigher, tailored specifically for the pharmaceutical industry. With over a decade of expertise, Samegram delivers solutions that exceed industry expectations. This article dives into the features, benefits, and practical applications of Samegram's checkweigher, showcasing how it can transform your production process.

Samegram's Boxed Medicine Automatic Checkweigher Machine: Precision and Efficiency Redefined

Samegram's checkweigher leverages state-of-the-art high-precision sensor technology to deliver unparalleled accuracy. This technology allows the device to detect minute weight variations, ensuring every boxed medicine meets exact standards—whether it's a small square package or a thick, long strip.

Key Features

Real-Time Detection and Rejection: The checkweigher scale continuously monitors product weight. If it detects anomalies such as over-packing, under-packing, or missing components, it triggers an alarm and removes the defective item via an automated rejection mechanism. This ensures only compliant products proceed.

● Exceptional Accuracy: Capable of detecting weight deviations as small as 0.1 grams. Samegram’s checkweigher guarantees precision across medium to high-speed production lines.

● Data Recording and Analysis: The device records checkweighing data in real-time and provides detailed quality reports. These insights help pharmaceutical companies optimize processes and maintain consistent standards.

● Seamless System Integration: Designed to integrate with MES (Manufacturing Execution Systems) and ERP (Enterprise Resource Planning) platforms, the in-line checkweigher enables real-time data sharing and streamlined operations.

● User-Friendly Design: With an intuitive interface and flexible customization options, the checkweigher adapts to diverse production needs, making it a versatile solution for pharmaceutical manufacturers.

Real-World Checkweigher Application: Ensuring Quality in Pharmaceutical Packaging

Consider a pharmaceutical company producing boxed antibiotics, each containing 10 blister packs, a patient leaflet, and a dosing spoon. Any deviation—such as a missing leaflet or an extra pack—could lead to compliance issues or customer complaints. Here’s how Samegram’s inline checkweigher ensures quality:

● Weight Verification: As boxes move through the production line, the checkweigher compares their weight to the preset standard. Any discrepancy triggers an immediate response.

● Automatic Rejection: Defective boxes are diverted to a rejection bin, preventing them from reaching the market.

● Actionable Insights: Data analysis reveals that 98% of boxes meet weight criteria, with the 2% rejection rate linked to missing leaflets. This prompts the company to address an upstream issue, improving overall efficiency.

This precision not only prevents costly recalls but also reinforces the company's commitment to quality. Samegram's checkweigher empowers pharmaceutical manufacturers to achieve automation, standardization, and lean management—cornerstones of modern production.

Why Choose Samegram? A Legacy of Excellence

Samegram has been a pioneer in industrial automation for over 10 years, delivering precision equipment to industries like pharmaceuticals, food, and logistics. Headquartered in Dongguan City, China, Samegram combines innovation with a customer-centric approach to provide tailored solutions worldwide.

Company Highlights

● Experience: With extensive experience in dynamic checkweighers technology, Samegram has supported countless pharmaceutical companies in optimizing their production lines.

● Expertise: Our team of engineers excels in automation solutions, addressing the unique challenges of pharmaceutical manufacturing.

● Authority: Samegram's checkweighers comply with international standards, earning recognition as a trusted industry leader.

● Trustworthiness: Client testimonials and successful case studies underscore our commitment to quality and reliability.

Learn more about our journey and mission on our About Us page.

Conclusion: Elevate Your Production with Samegram's High Speed Checkweigher

In an industry where accuracy is paramount, Samegram's automated checkweigher for boxed medicine offers a transformative solution. Its advanced features—high-precision sensors, real-time detection, and system integration—make it indispensable for pharmaceutical companies aiming to enhance quality and efficiency.

Partner with Samegram and benefit from our proven expertise and innovative technology. Visit our Products page to explore our full range of checkweigher solutions and see how we can help you achieve excellence in pharmaceutical production.

Related Hot-sale Checkweighers

SWSR-750TC6 is a stainless steel weight sorting machine designed for food use,very suitable for fish ,seafood and poulty

SCL-7035L5 is a weigh price labeler that integrates a weighing machine with label printer(s),which is very widely used

The SC3-10060L50 is an end of line checkweigher with built-in rejector, especially designed for large items.

SCP2 is a dual lane checkweigher with double belt conveyer, Very suitable for fast production lines such as food and medicine

SBW-2512B12 is a multi head combination weigher ideal for fast, precise dosing,also known as linear combination scale.