Type of Checkweighers, How They Work, and Industry Uses

- Share

- Issue Time

- Jul 16,2025

Summary

Discover everything about Checkweighers—from their types and operating principles to practical applications. See how SameGram delivers cutting-edge solutions for precise weight control across industries.

Introduction to Checkweighers

A checkweigher is a vital tool in industries like manufacturing, packaging, and logistics, ensuring products meet precise weight standards. The Checkweigher system uses load cells to detect the weights of items and compares them with predefined specifications. If a product's weight deviates from the target weight, the Dynamic checkweigher activates a rejection mechanism to remove it from the batch. These systems enhance quality control, reduce waste, and ensure compliance with regulations by automatically weighing items on production lines. Whether you're in food processing, pharmaceuticals, or shipping, understanding the types of checkweighers available can significantly improve your operational efficiency.

At SameGram, we pride ourselves on delivering advanced checkweighing solutions that combine precision, durability, and innovation. Our expertise makes us a trusted partner for businesses seeking reliable weight verification systems.

What is an In-motion Checkweigher?

An in-motion checkweigher is a dynamic weighing machine that measures product weight as it moves along a conveyor, offering real-time verification without halting production. This distinguishes it from static scales and makes it ideal for high-speed environments.

Key Functions

● Weight Verification: Confirms products fall within acceptable weight ranges.

● Quality Assurance: Maintains consistency for customer satisfaction and compliance.

● Waste Reduction: Identifies and removes defective items early.

● Data Insights: Tracks weight trends for process optimization.

Key Components of a Dynamic Checkweigher

● Conveyor Belt: Transports products to the weight station continuously.

● Load Cells: Placed under the weight platform, they detect the weight of each product and convert the force applied by each item into electrical signals processed by the control unit.

● Control Unit: Compares the item's weight with a preset target value. If the weight is incorrect, it triggers the rejection mechanism.

● Rejection System: Removes out-of-spec products from the production line. Types include push arm, air jet, drop flap, and diverter systems.

Our company's checkweigher machines are equipped with high-precision load cells and sophisticated control units, ensuring accurate measurements and efficient rejection of non-conforming products.

Types of Checkweigher Scales

Checkweigher Scales come in various forms, each suited to specific needs. Here’s an overview of the main types of in line checkweighers:

1. In-Motion Checkweighers or Dynamic Checkweighers

In-Motion checkweighers systems weigh products as they move, perfect for high-speed lines。 They can accurately record the weights of items moving over the conveyor belt without causing any disruptions. Dynamic checkweighers contain infeed belts to maintain proper product spacing and reject belts to remove out-of-spec items. They utilize high-frequency load cells or electromagnetic force restoration to ensure accuracy in readings and efficiency in the workflow.

2. Static Checkweighers

Unlike their dynamic counterparts, static checkweighers require products to come to a complete stop before they can be weighed. These checkweighers are ideal for industries dealing with smaller, delicate, and high-value products that need to be weighed with utmost accuracy. The static design allows for better quality control in sectors like pharmaceuticals, chemical labs, jewelry manufacturing, and sensitive mechanical parts manufacturing.

3. Combination Checkweighers

Combination checkweighers go beyond simply measuring weight. They integrate additional inspection capabilities such as metal detection, X-ray inspection, and barcode scanning. By combining different functionalities into a single unit, manufacturers can streamline their quality control processes and save valuable floor space. These checkweighers are commonly used in industries where a comprehensive assessment of product integrity is essential, such as the food and beverage industry, ensuring not only weight accuracy but also the detection of foreign objects or contaminants.

4. Washdown Checkweighers

Washdown checkweighers are specifically designed for industries that require strict hygiene standards, such as food processing, cosmetics, or pharmaceuticals. These checkweighers are built to withstand harsh cleaning processes, including high-pressure washes and chemical disinfection, while maintaining their accuracy and performance. They have stainless steel frames and IP65 or higher waterproof ratings, ensuring resistance to dust, water, and even corrosive cleaning agents.

5. Heavy Weight Checkweighers

Heavy-weight checkweighers are designed to weigh heavy products, such as pallets of bottled drinks, aquatic animals, or sacks of flour. They have a large-scale platform that can accommodate heavy products and feature a slow belt speed ranging between 5 to 60 meters per minute.

6. Combi-Check Checkweighers

Combi-check checkweighers are dynamic checkweighers integrated with a metal detector or X-ray inspection machine. These checkweighers simultaneously check the weight and the presence of metal contaminants or other foreign objects. The metal detector or X-ray machine is placed above the conveyor belt before the in-motion checkweigher platform. If a foreign object is detected, the machine stops the conveyor belt and triggers an alarm horn with an LED light. The product is then manually removed from the conveyor belt. Automated rejection systems and rejection lines can also be used rather than a manual process.

7. Sorting Checkweighers

Sorting checkweighers are dynamic checkweighers that direct products to different production lines or chutes based on weight. They have a conveyor belt with multiple product chutes branching off of it. As the products pass over the scale platform, they are weighed and routed to the appropriate chute corresponding to their weight range.

8. Weigh Price Labelling Checkweighers

Weigh price labelling machines are dynamic checkweighers that integrate a labelling machine. These checkweighers weigh the product, calculate the price based on the weight, and print and apply the label with the weight and price information in one process.

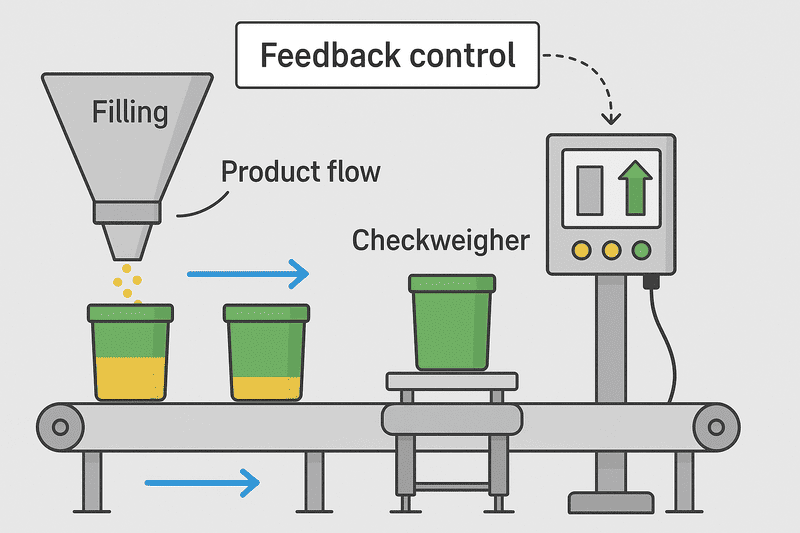

How Inline Checkweighers Work

Inline checkweighers operate in three stages:

1. Infeed: Products enter the system and are spaced for weighing.

2. Weighing: Load cells measure weight against set tolerances.

3. Outfeed: Acceptable items proceed; others are rejected.

Advanced technologies like strain-gauge load cells ensure precision, while modern interfaces provide operational ease.

Applications of Checkweigher Combination Systems

Checkweigher combination cystems find extensive applications across various industries. Some of the main uses include:

● Ensuring packaged goods meet acceptable weight standards in food processing, pharmaceuticals, and other industries, to guarantee regulatory compliance and customer satisfaction.

● Detecting missing parts in sensitive devices or packaged kits.

● Verifying that products in metalwork and plastic industries have the right weights, facilitating the correct amount of material usage and ensuring product reliability.

● Regulating packaging speed by adjusting product spacing on the conveyor belt.

● Preventing accidental product giveaways in high-volume production.

● Measuring pallets and generating shipping labels in warehousing and logistics operations, ensuring transparency and reducing fraud.

● Classifying products into different weight categories.

● Providing real-time data and insights to manufacturers to identify trends that can contribute to streamlined operations.

● Ensuring better inventory management by preventing understocking or overstocking during product procurement.

Why Choose SameGram?

Our company is committed to providing checkweigher combination systems that are not only precise and reliable but also innovative and tailored to meet the evolving needs of industries. With our extensive experience and expertise in the automation field, we have developed a reputation for delivering high-quality checkweighing solutions that help businesses optimize their production processes and maintain stringent quality standards.

We continuously strive for excellence in quality and take it as our responsibility to provide stable and reliable weighing system solutions for various industries. This has helped us establish ourselves as a leading brand in the automatic weighing industry.

Discover our checkweigher products or contact us to enhance your production line.

Related Hot-sale Checkweigher

SBW-2512B12 is a multi head combination weigher ideal for fast, precise dosing,also known as linear combination scale.

SC2-8050L30 is a high-capacity dynamic checkweigher for packages up to 30 kg. This machine is very economical and widely used.

SC3-10070L80 is a heavy duty checkweigher ideal for large items up to 80 kg. This machine is also known as roller checkweigher.

SWSD-4523L2 is a weight sorter with food-grade material and IP65 protection ,very suitable for fish and shrimp weight sorting.

SCL-10060L50 is an automatic weigh price labeler with scanning, weighing scale label printing, and template customization.