Efficient Checkweigher Solution for Hardware Screw Packages Sorting by Samegram

- Share

- Issue Time

- Jul 25,2025

Summary

Explore how Samegram's cutting-edge checkweigher system boosts accuracy in hardware screw packaging with automated weight checks and fast sorting, ensuring top-quality products and streamlined production.

In the hardware industry, ensuring the accuracy and completeness of screw packages is critical to maintaining product quality and customer satisfaction. Missing or leaking parts in screw packages can lead to costly production errors, customer complaints, and damage to a company’s reputation. To address this challenge, Samegram, a leading provider of automated weighing and sorting solutions, has developed an innovative Checkweigher system specifically designed for hardware screw packages. This advanced system ensures that every screw package meets the required weight specifications, automatically detecting and sorting out any defective products.

The Problem: Missing or Leaking Parts in Screw Packages

During the packaging process of hardware screw packages, there is always a risk of missing or leaking parts. These defects can occur due to various reasons, such as machine malfunctions, human error, or inconsistencies in the production line. Manually inspecting each package for accuracy is time-consuming, inefficient, and prone to errors. As a result, manufacturers need an automated solution that can quickly and accurately detect these issues, ensuring that only qualified products reach the market.

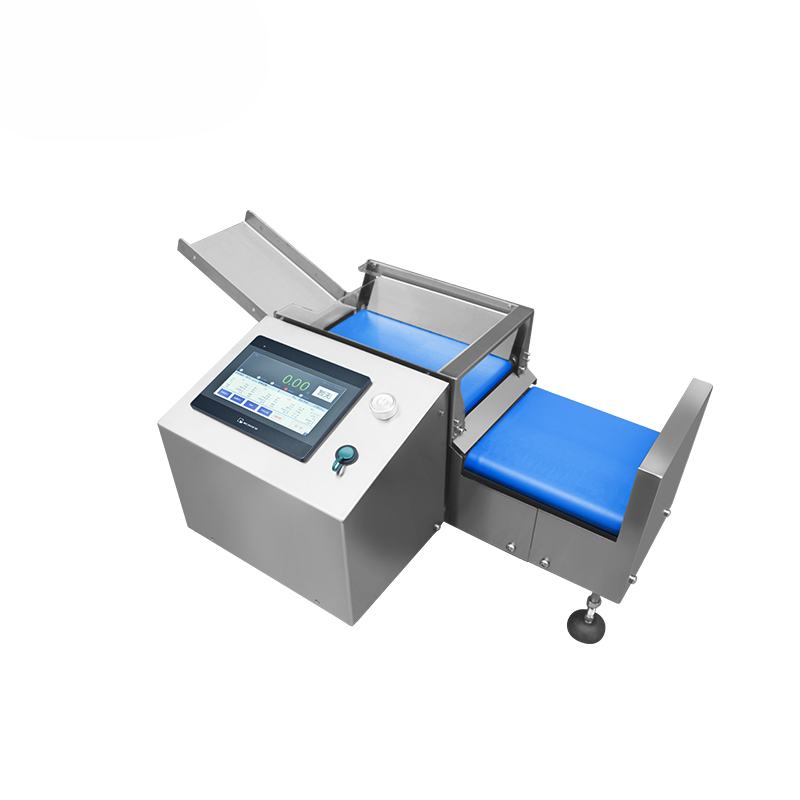

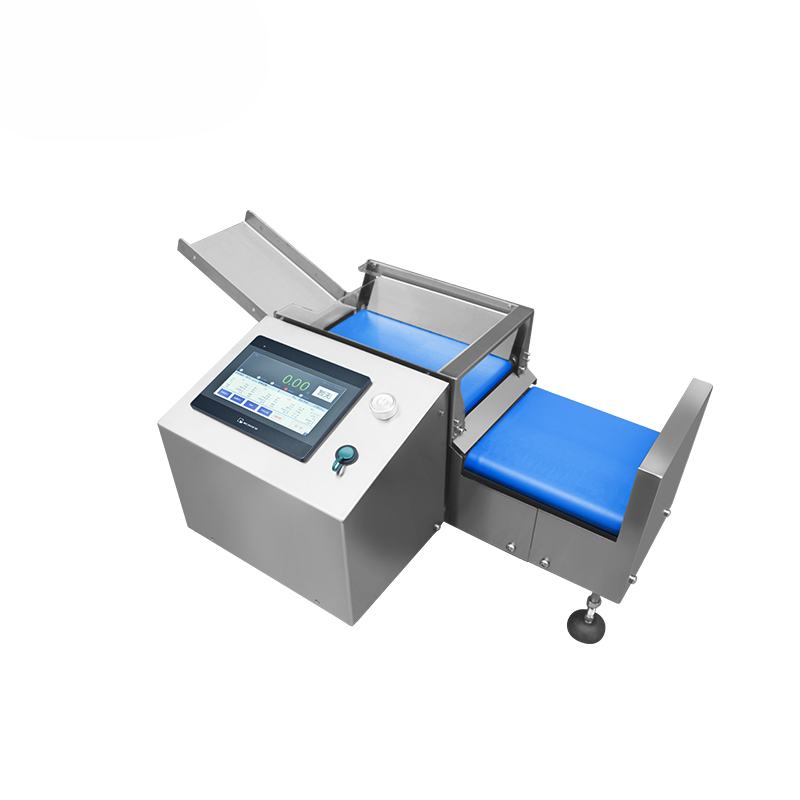

Samegram's Solution: Forward and Reverse Weight Sorting Scale

Samegram's checkweigher system, featuring a forward and reverse weight sorting scale, provides an efficient and automated solution to this problem. This system is designed to handle the unique challenges of hardware screw packages, offering precise weight detection and rapid sorting capabilities.

How It Works

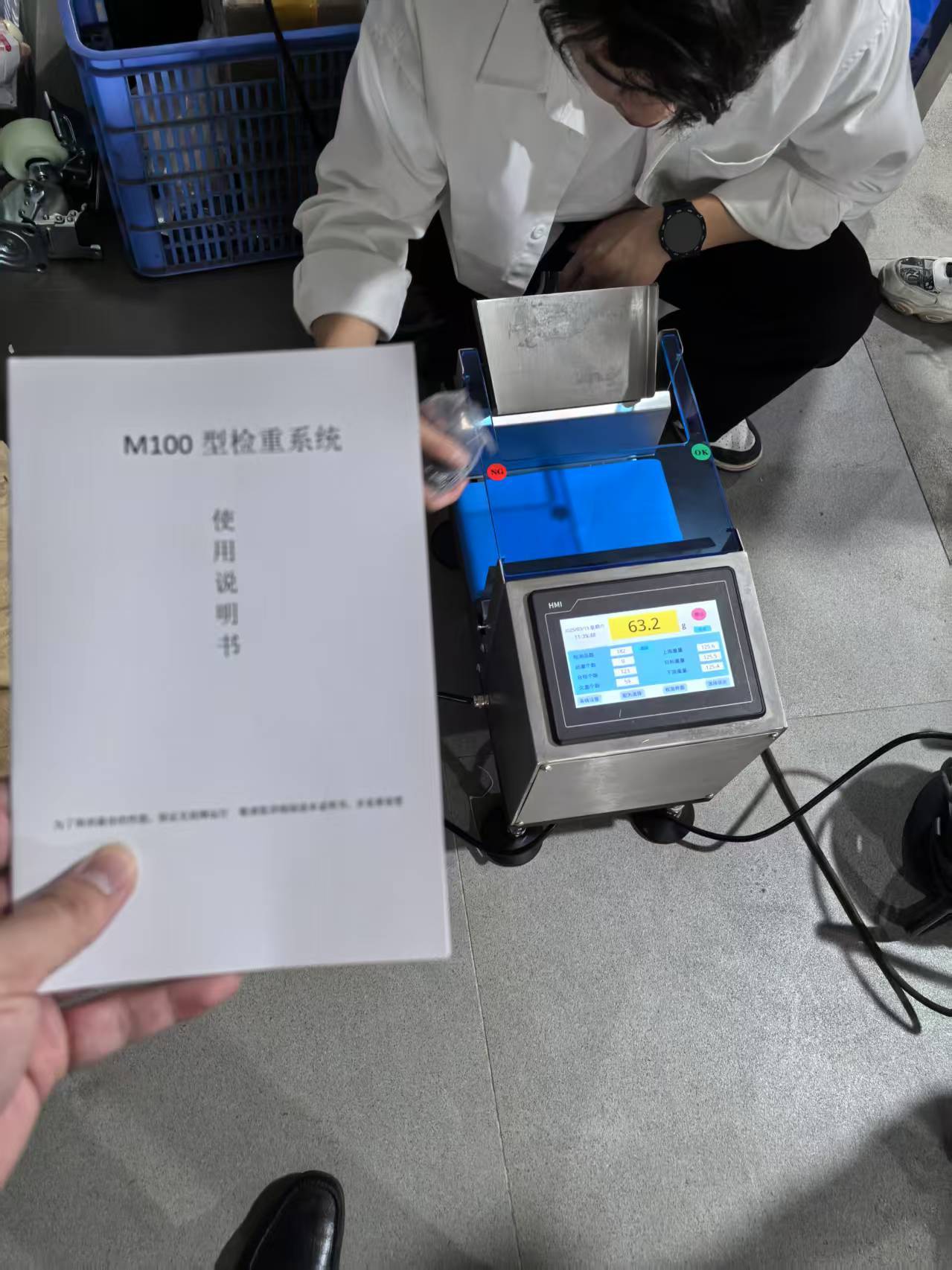

1. Automated Weight Detection: The operator places the screw package onto the sorting scale. The dynamic checkweigher quickly measures the weight of each package and compares it to the preset qualified weight range.

2. Real-Time Sorting: If the weight of the screw package falls below the qualified range, the system identifies it as a defective product. The sorting mechanism is immediately activated, causing the defective package to fall to the left for collection. Conversely, if the weight is within the qualified range, the package is judged as qualified and automatically guided to the right for collection.

3. Efficient and Accurate: The entire process is fully automated, ensuring high-speed detection and sorting without compromising accuracy. This not only improves production efficiency but also guarantees that only qualified products are shipped to customers.

Key Features of Samegram’s Dynamic Checkweigher for Precision Weighing

1. High Precision Weighing: Utilizes advanced load cell technology to achieve accurate weight measurements, ensuring even the smallest deviations are detected.

2. Automated Sorting Mechanism: Features a forward and reverse sorting scale that quickly separates qualified and defective products, minimizing manual intervention.

3. User-Friendly Interface: Equipped with an intuitive control panel that allows operators to set weight parameters and monitor the sorting process easily.

4. Durable Construction: Built with high-quality materials to withstand the demands of industrial environments, ensuring long-term reliability.

5. Compact Design: Space-saving design that can be easily integrated into existing production lines without requiring significant modifications.

Benefits of Using Samegram's Checkweigher System for Screw Packages

1. Enhanced Product Quality

By automatically detecting and removing defective screw packages, Samegram's in-motion checkweigher ensures that only products meeting the highest quality standards reach customers. This reduces the risk of customer complaints and returns, enhancing brand reputation.

2. Increased Production Efficiency

The automated sorting process significantly speeds up the inspection process, allowing manufacturers to handle large volumes of screw packages without bottlenecks. This leads to higher throughput and improved overall efficiency.

3. Cost Savings

By minimizing the number of defective products that make it to the market, manufacturers can reduce waste and avoid costly recalls. Additionally, the system's automation reduces the need for manual labor, further lowering operational costs.

4. Compliance with Industry Standards

Samegram's inline checkweighers help manufacturers comply with industry regulations and standards by ensuring that all products meet the specified weight requirements. This is particularly important in industries where precision and accuracy are critical.

5. Real-Time Data Monitoring

The system supports RS232/485 and Ethernet communication interfaces, allowing seamless integration with ERP and MES systems. This enables real-time uploading of production data, transparent monitoring, and efficient management of the production process.

Why Choose Samegram?

Samegram is a trusted name in the field of automated weighing and sorting solutions, with a proven track record of delivering high-quality, reliable products. Here's why Samegram stands out:

● Expertise and Experience: With years of experience in the industry, Samegram has developed a deep understanding of the challenges faced by manufacturers. Our team of experts is dedicated to providing innovative solutions that meet the specific needs of our clients.

● Wide Range of Products: In addition to our checkweigher systems, Samegram offers a comprehensive range of weighing and sorting solutions, including weight sorting machines, automatic labeling machines, and roller conveyor scales. Explore our full product range here.

● Customization Options: We understand that every production line is unique. That’s why we offer customized solutions tailored to your specific requirements, ensuring seamless integration and optimal performance.

● Commitment to Quality: At Samegram, quality is our top priority. Our products are manufactured using the highest quality materials and undergo rigorous testing to ensure they meet the highest standards of performance and durability.

● Exceptional Customer Support: From initial consultation to after-sales service, our team is here to support you every step of the way. We are committed to ensuring your satisfaction and the success of your operations.

Customer Success Story

One of our clients, a leading hardware manufacturer, faced significant challenges with missing parts in their screw packages. After implementing Samegram's checkweigher system, they experienced a dramatic improvement in their production process:

● Reduced Defect Rate: The defect rate dropped by 85%, ensuring that nearly all products shipped were of the highest quality.

● Increased Efficiency: The automated sorting process allowed them to increase their production speed by 30%, meeting growing demand without compromising quality.

● Cost Savings: By reducing waste and minimizing manual inspections, the company saved over $10,000 in the first year alone.

This success story is just one example of how Samegram’s checkweigher system can transform your production line.

Conclusion

In today's competitive manufacturing landscape, ensuring product quality and efficiency is more important than ever. Samegram’s checkweigher system for hardware screw packages provides a reliable, automated solution to detect and sort defective products, helping you maintain the highest standards of quality while optimizing your production process.

If you’re ready to take your production line to the next level, contact Samegram today to learn more about our automatic checkweigher machine solutions and how we can customize them to meet your specific needs.

Call to Action: Visit our product page to explore our full range of weighing and sorting solutions, or contact us for a personalized consultation.

Related Hot-sale Checkweigher

SC3-Lpro is a weighing scale for parcels with a 2000×1500mm platform, suitable for extra large packages.

SC2-8040L15 is an weight checker machine with advanced data tracking and flexible speed control. excellent performance weigher

SC3-10060L30 is an Dynamic Roller Checkweigher for large packages, economical and widely used in various outer box products

SCP-L is a static weighing scale integrated with a printer, ideal for warehouses needing manual, flexible parcel weigh solution

SC-L-8070L20 is a dynamic parcel weighing scale with two weighing platforms which has greater throughput while ensuring speed