High-precision X-ray Inspection Systems for Packaged Products XSS Series

- Model

- XSS series

Item specifics

- Conveyor Belt Speed

- 10-60 m/min

- Inspection Weight

- <10Kg

- Waterproof Rating

- Conveyor is lP66, other parts are lP54

- Equipment Materials

- 304 stainless steel, brushed finish

- Detector Resolution

- 0.2/0.4mm High-definition TDI

Review

Description

Detail Information

High-precision X-ray Inspection Systems for Packaged Products XSS Series

Introduction

Discover our advanced industrial x-ray inspection systems and high-performance x ray inspection machines, engineered for superior quality control. We provide specialized food x-ray inspection systems and versatile x-ray inspection systems for packaged products. Our solutions feature a cutting-edge real time x ray inspection system, powered by a unique ZeroShot-SvDetector deep learning algorithm for unmatched accuracy. This system delivers immediate, high-precision detection (down to 0.2mm) of foreign bodies like metal, glass, and hard plastics. With robust 304 stainless steel construction and 4G remote support, we ensure the highest safety and operational uptime for your production line.

High-precision X-ray Inspection Systems for Packaged Products XSS Series Features

High-precision X-ray Inspection Systems for Packaged Products XSS Series Technical Parameters

| Model | XSS-2410 | XSS-4016 | XSS-6030 | XSS-6040 | XSS-7040 |

| X-ray Source (Unit: W) | Maximum sizes of 150/210/240/350 are available. | ||||

| Detector Resolution | 0.2/0.4mm High-definition TDI (actual accuracy is affected by the sample material and is subject to testing). | ||||

| Inspection Accuracy | SUS sphere:0.4mm,glass:1.0mm, ceramic: 1.0mm, SUS wire: 0.2*5mm | ||||

Operating Software | Self-developed Sooview detection software | ||||

Human Machine lnterface | 21.5-inch touchscreen | ||||

Conveyor Belt Speed | 10-60 m/min | ||||

Inspection Weight | <10Kg | ||||

Inspection Dimensions | 240*50mm | 400*120mm | 600*200mm | 600*300mm | 700*300mm |

Power Supply | AC 220V2.0kw 50hz | ||||

Temperature and Humidity | Ambient temperature 0~45'C,relative humidity 30~85%(non-condensing) | ||||

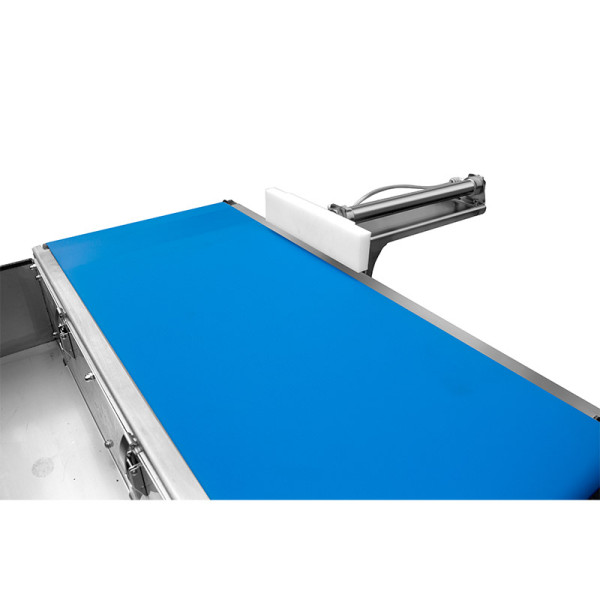

Waterproof Rating | Conveyor is lP66, other parts are lP54 | ||||

Equipment Materials | 304 stainless steel, brushed finish | ||||

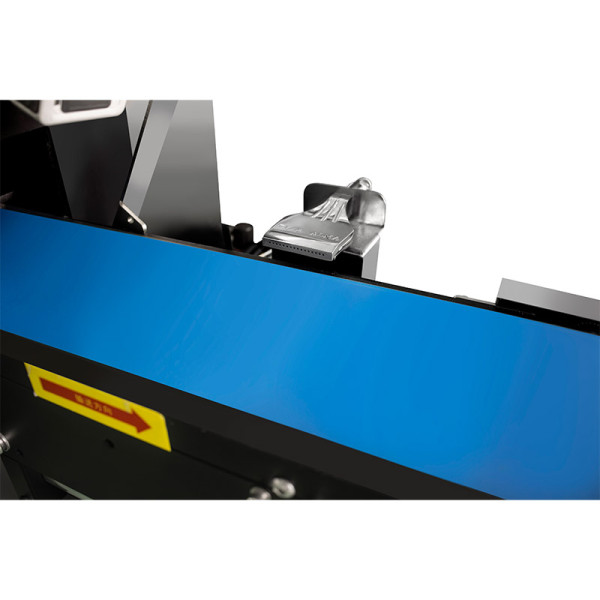

Available Rejection Systems for High-precision X-ray Inspection Systems XSS Series

Up and Out Rejector for checkweigher and metal detector systems — stable, gentle, and precise for soft or thick products.

Fast swing arm works with checkweigher or metal detector systems to remove defective boxes and bags up to 1 kg.

Samegram’s Belt Drop rejector is a high speed rejector using pneumatic lift rods to gently remove thin bags and flat products.

The heavy-duty pusher rejector pair with checkweigher systems to deliver accurate, mid-speed removal of heavy, boxed items.

Air Jet Rejectors use powerful air bursts to remove lightweight or low-density items. Ideal for fast-moving lines.

File Downloads

For more product related parameter files, please contact us.

High-precision X-ray Inspection Systems for Packaged Products Applications

Bagged Tea Inspection

Ensuring contaminant-free, high-quality bagged tea using precise X-ray inspection technology

Bagged Potato Chips Inspection

High-speed X-ray detects foreign bodies and defects in packaged potato chips for reliable quality control.

vacuum-packed peanuts Inspection

High-precision X-ray detects foreign bodies and packaging defects in vacuum-packed peanuts for safer production.