Standard Machine for X ray Inspection Machine of Bagged Products XSS series

- Model

- XSS series

Item specifics

- Conveyor Belt Speed

- 10-60 m/min

- Inspection Weight

- <10Kg

- Detector Resolution

- 0.4mm

- Waterproof Rating

- Conveyor is lP66, other parts are lP54

- Equipment Materials

- 304 stainless steel, brushed finish

Review

Description

Detail Information

Standard Machine for X ray Inspection Machine of Bagged Products XSS series

Introduction

Leverage AI-powered ZeroShot-Sv Detector deep learning algorithm with this advanced automated x-ray inspection system. Designed specifically for the x-ray inspection systems food industry, this versatile x ray inspection machine accurately detects a wide range of foreign objects—including metal, glass, ceramic, and stone—and verifies package seal integrity in real-time. It's the ideal x-ray machine for food inspection and a reliable x-ray food inspection system for packaged product, offering stable performance across small, medium, and large packages, and featuring 4G connectivity for fast remote support. Secure your brand reputation with a high-precision x ray food inspection systems solution.

Standard Machine X-ray Inspection System of Bagged Products XSS series Features

Standard Machine X-ray Inspection System of Bagged Products XSS Series Technical Parameters

| Model | XSS-2410 | XSS-4016 | XSS-6030 | XSS-6040 | XSS-7040 |

| X-ray Source (Unit: W) | 210 | 240 | 240/350 | 240/350 | 350 |

| Detector Resolution | 0.4mm (unloaded; actual accuracy may vary depending on the sample material and is subject to testing) | ||||

| Inspection Accuracy | SUS sphere:0.4mm,glass:1.0mm, ceramic: 1.0mm, SUS wire: 0.2*5mm | ||||

Operating Software | Self-developed Sooview detection software | ||||

Human Machine lnterface | 21.5-inch touchscreen | ||||

Conveyor Belt Speed | 10-60 m/min | ||||

Inspection Weight | <10Kg | ||||

Inspection Dimensions | 240*50mm | 400*120mm | 600*200mm | 600*300mm | 700*300mm |

Power Supply | AC 220V2.0kw 50hz | ||||

Temperature and Humidity | Ambient temperature 0~45'C,relative humidity 30~85%(non-condensing) | ||||

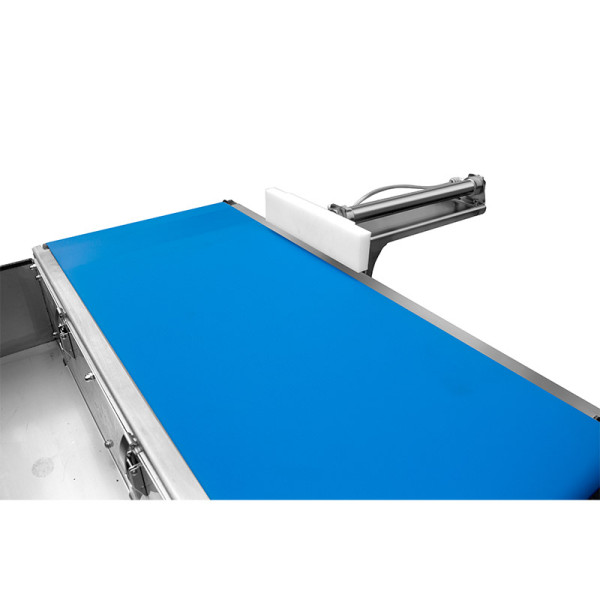

Waterproof Rating | Conveyor is lP66, other parts are lP54 | ||||

Equipment Materials | 304 stainless steel, brushed finish | ||||

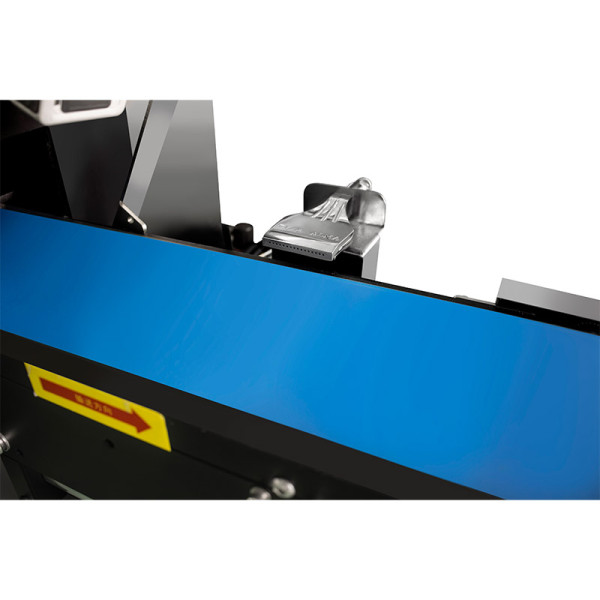

Available Rejection Systems for Standard Machine X-ray Inspection System XSS Series

Up and Out Rejector for checkweigher and metal detector systems — stable, gentle, and precise for soft or thick products.

Fast swing arm works with checkweigher or metal detector systems to remove defective boxes and bags up to 1 kg.

Samegram’s Belt Drop rejector is a high speed rejector using pneumatic lift rods to gently remove thin bags and flat products.

The heavy-duty pusher rejector pair with checkweigher systems to deliver accurate, mid-speed removal of heavy, boxed items.

Air Jet Rejectors use powerful air bursts to remove lightweight or low-density items. Ideal for fast-moving lines.

File Downloads

For more product related parameter files, please contact us.

Standard Machine X-ray Inspection System of Bagged Products Industry Applications

To ensure industry relevance and customer resonance, the XSS Series focuses on typical industries where bagged packaging and quality risk coexist.

In Pharmaceuticals and Health Products, powders, granules, herbal medicines, supplements, and medical consumables are commonly packed in sachets or sealed bags.

The XSS Series enables:

·Detection of metal, glass, stone, dense plastic, and other contaminants

·Identification of poor sealing or air leakage that may compromise product stability

·Non-destructive inspection suitable for GMP and HACCP processes

·This ensures product safety, regulatory compliance, and long-term shelf-life protection.

For Personal Care and Cosmetics Products, such as creams, gels, powders, and wipes packed in sachets or bags, visual inspection alone is often insufficient.

The XSS Series supports:

·Reliable foreign object detection in opaque or multilayer packaging

·Detection of internal paper-based contaminants (e.g. packaging inserts, labels, or magazine fragments)

·Early identification of leaking or under-sealed packages that may cause drying, oxidation, or contamination

·This helps manufacturers protect brand image and reduce customer complaints.

In Bakery Confectionery, Snacks and Nuts, raw materials and high-speed packaging increase the risk of foreign object contamination.

Typical applications include:

·Bagged biscuits, cookies, chocolates, candies, nuts, and snack mixe

·Detection of stones, shell fragments, metal particles, and dense impurities

·Identification of sealing defects that may lead to moisture ingress or loss of freshness

The XSS Series maintains detection accuracy even with irregular shapes and mixed contents.

Bagged frozen or chilled products in Fish, Seafood and Meat require strict control of both product safety and package integrity.

The system provides:

·Detection of bones, metal fragments, hooks, and dense foreign materials

·Reliable inspection of vacuum-packed or frozen bagged products

·Identification of air leakage that may result in freezer burn, spoilage, or contamination

This supports higher food safety standards and reduces downstream quality risks.

Standard Machine X-ray Inspection System of Bagged Products Case Studies

Bagged Snacks Inspection

Ensuring contaminant-free, high-quality packaged snacks through precise X-ray inspection

Bagged Meat Snacks Inspection

Accurately detecting foreign objects and ensuring safety in bagged meat snack products

Bagged Nuts X-ray Inspection

Ensuring bagged nuts safety and quality by detecting contaminants with advanced X-ray inspection system.

Standard Machine X-ray Inspection System and Package Integrity Capabilities

System Overview

Combines high-resolution X-ray hardware with intelligent image-processing software

Delivers a comprehensive inspection solution beyond traditional foreign object detection

Designed specifically for sealed and bagged products

Foreign Object Detection Performance

·Reliably detects a wide range of contaminants, including:

Metal,Glass,Stone,Bone,Ceramics,Dense rubber,High-density plastics

·Applies multi-level detection algorithms, such as:

Shape recognition,Brightness comparison,Gradient analysis

·Maintains stable detection accuracy across:

Different bag sizes,Various packaging materials,Variable product densities,Complex or irregular product shapes

Intelligent Software and System Advantages

·Product library supporting over 1000 SKUs

·Self-learning function that automatically adapts to product variations and reduces false rejects

·Real-time X-ray image display with abnormal image storage for traceability and quality audits

·Multi-level permission control to ensure:Safe operation,Data integrity,Controlled maintenance access

·Intelligent system architecture minimizes manual intervention while ensuring consistent inspection performance

Package Integrity and Air Leakage Detection

·Provides package integrity inspection in addition to foreign object detection

·Analyzes subtle density differences and internal air distribution inside sealed packages

·Capable of:

Detecting air leakage caused by poor sealing, micro-holes, or incomplete vacuum conditions.

Identifying under-sealed or improperly sealed bags before market release

Detecting internal paper-based inclusions, such as: Instruction. Leaflets, Magazine fragments, Other unintended packaging inserts introduced during manual or semi-automatic packing.

Applicable Product Types

·Vacuum-packed products

·Modified-atmosphere packaging (MAP)

·Oxygen-sensitive goods

·Moisture-sensitive products

·Products with strict shelf-life, hygiene, and quality requirements

Quality and Risk Reduction Benefits

·Combines foreign object detection with package integrity and leak detection

·Significantly reduces recall and complaint risk

·Improves overall quality assurance processes

·Helps manufacturers protect:

Product safety

Packaging integrity

Brand reputation

Standard Machine X-ray Inspection System of Bagged Products FAQs

Q1: Can the XSS Series detect air leakage in sealed packages?

Yes. The system can identify abnormal internal air distribution caused by poor sealing or micro-leaks.

Q2: Is it suitable for aluminum foil or metallized packaging?

Yes. X-ray inspection is not affected by aluminum foil or metallized films.

Q3: Can it detect non-metal contaminants like paper or plastic?

Yes. Dense plastics, rubber, and paper-based contaminants can be detected based on density differences.

Q4: Is X-ray inspection safe for operators?

Yes. The system uses thickened steel shielding and protective curtains, fully compliant with radiation safety standards.