Streamlined Production with Weigh Price Labeling Systems | SameGram Solutions

- Share

- Issue Time

- Oct 15,2025

Summary

Discover how weigh price labeling systems boost efficiency in food and manufacturing lines. Automate weighing, pricing, and labeling for accuracy and cost savings. Explore SameGram's integrated solutions today.

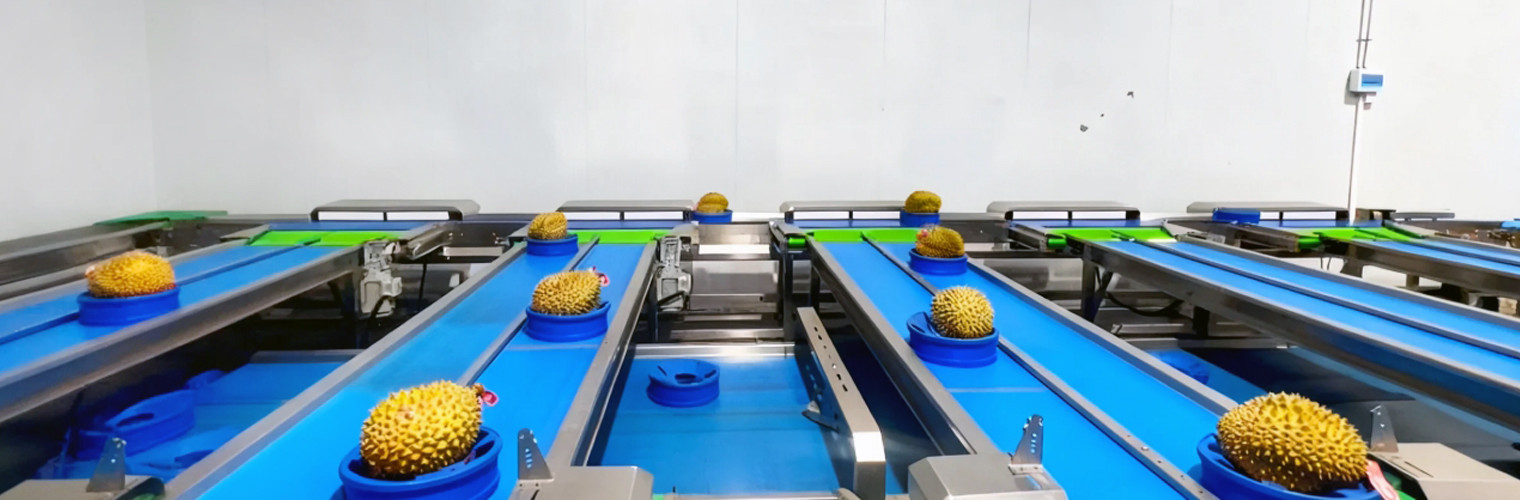

In today's fast-paced manufacturing world, efficiency isn't just a goal—it's a necessity. Weigh price labeling systems are transforming how businesses handle product packaging, ensuring accuracy, speed, and compliance all in one seamless process. At SameGram, we've specialized in these innovative solutions for years, helping companies like yours streamline operations and boost profitability. Whether you're in food processing, retail, or general manufacturing, integrating a weigh price labeller can make all the difference. Let's dive into how these systems work and why they're essential for modern production lines.

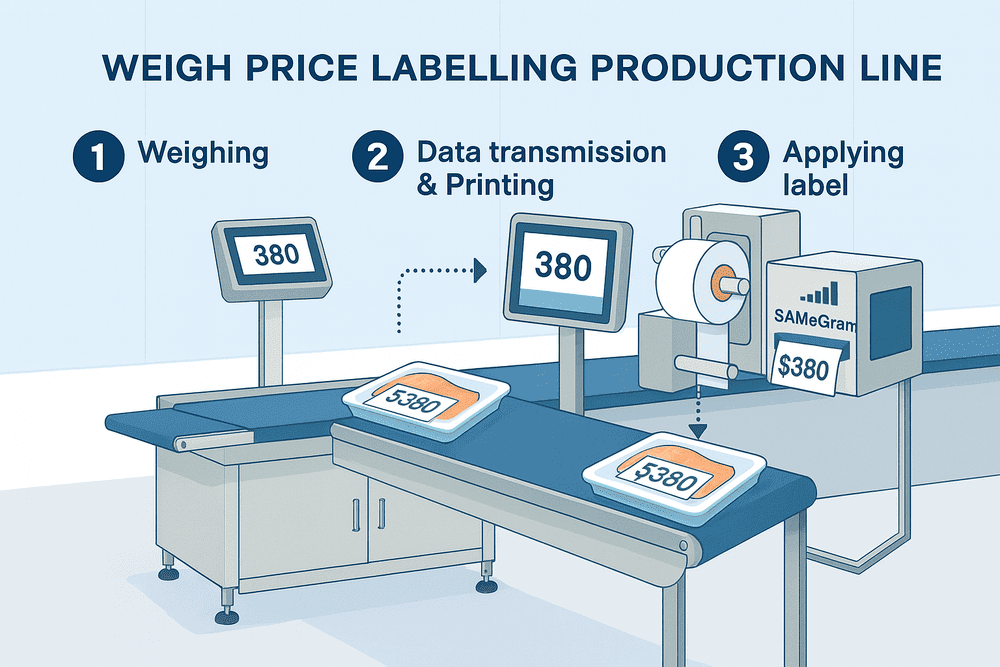

A weigh price labeller is more than just a machine—it's a complete system that combines weighing, data processing, printing, and labeling into a single, automated workflow. Imagine a product gliding along a conveyor: it first hits the checkweigher for precise weight measurement, then that data is instantly sent to a computer. The system calculates the price based on weight (perfect for variable-weight items like meats or produce), prints a custom label with details like price, barcode, and expiration date, and applies it right there on the line. No manual intervention, no errors, and everything happens on the same conveyor belt.

This setup addresses common pain points in production, such as inconsistent labeling, wasted time on manual checks, and compliance issues with regulations like food safety standards. For instance, if you're dealing with catch-weight products—items sold by weight rather than fixed units—a weigh price labeling system ensures every label reflects the exact weight and price, reducing overfill losses and underweight complaints. Our systems at SameGram are designed with user-friendly interfaces, making them accessible even for teams without extensive technical training.

Key Applications Across Industries

Weigh price labeling systems shine in industries where precision and speed are critical. In the food sector, they're indispensable for handling fresh produce, meats, and dairy, where weights vary and accurate pricing prevents revenue leaks. Retail operations use them to prepare pre-packaged goods efficiently, ensuring shelves are stocked with correctly labeled items that meet consumer expectations. Manufacturing lines, especially those dealing with bulk or variable items, benefit from the automation to maintain high throughput without sacrificing quality.

For example, in meat processing—a notoriously challenging area due to variable weights—our systems integrate seamlessly to manage catch-weight effectively. This not only streamlines inventory but also enhances traceability, crucial for recalls or audits. If you're exploring solutions tailored to your field, check out our Industry Applications Page for case studies in food, pharmaceuticals, and more. We've helped countless clients adapt these systems to their unique needs, from small-batch runs to high-volume production.

Incorporating related tools like checkweighers and automatic labeling machines further enhances versatility. A checkweigher machine ensures weights are spot-on, while an automatic label applicator machine handles the final step with precision, making the entire process foolproof.

Step-by-Step Process Breakdown

To truly appreciate the value, let's break down how a weigh price labeller operates in real time. This isn't theoretical—it's based on proven workflows we've implemented at SameGram.

Weighing Stage

Products enter the system via a conveyor. Our high-accuracy checkweigher captures the weight dynamically, even at speeds up to 25 meters per minute. This in-motion checkweigher handles everything from lightweight packages to heavier cases, with tolerances as tight as ±0.1g for precision needs.

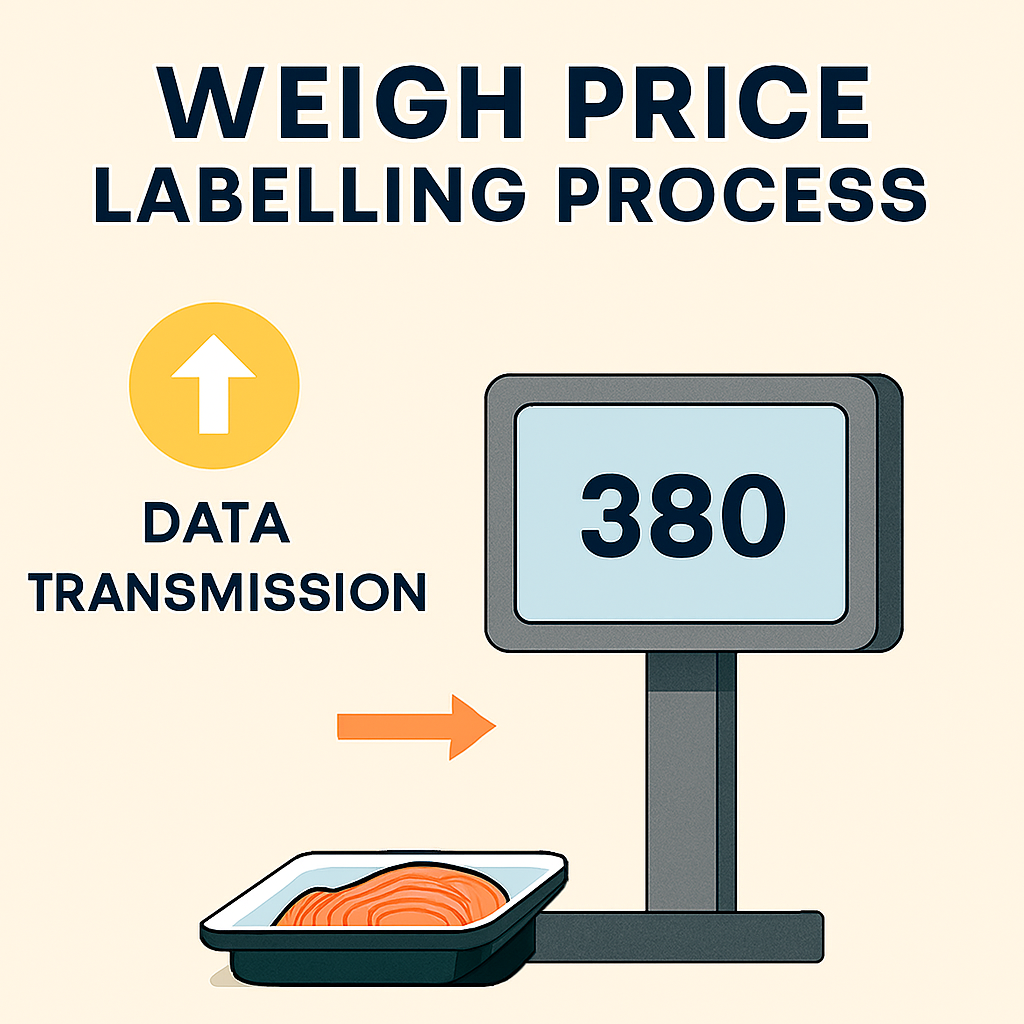

Data Transmission

The weight data is transmitted instantly to the system's controller via reliable protocols like EtherNet/IP or Modbus-TCP. Here, software calculates the price, incorporates variable info like batch numbers or QR codes, and prepares the label template. Our proprietary software ensures seamless integration with your ERP or MES systems, pulling in real-time data for accuracy.

Printing the Label

Using thermal transfer technology at 600 dpi resolution, the printer creates clear, durable labels. This step eliminates errors from pre-printed rolls, as everything is generated on-demand. For high-speed lines, our systems support up to 40 labels per minute, matching your production rhythm.

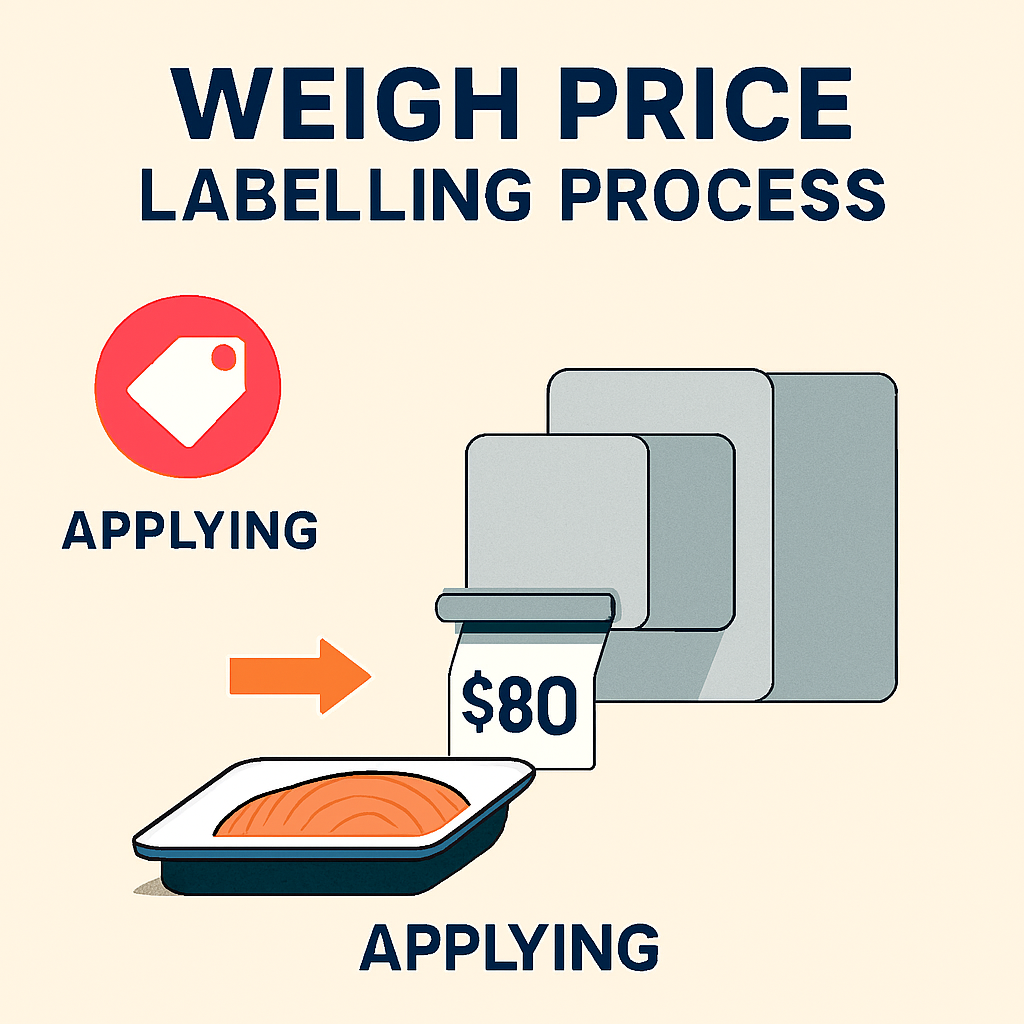

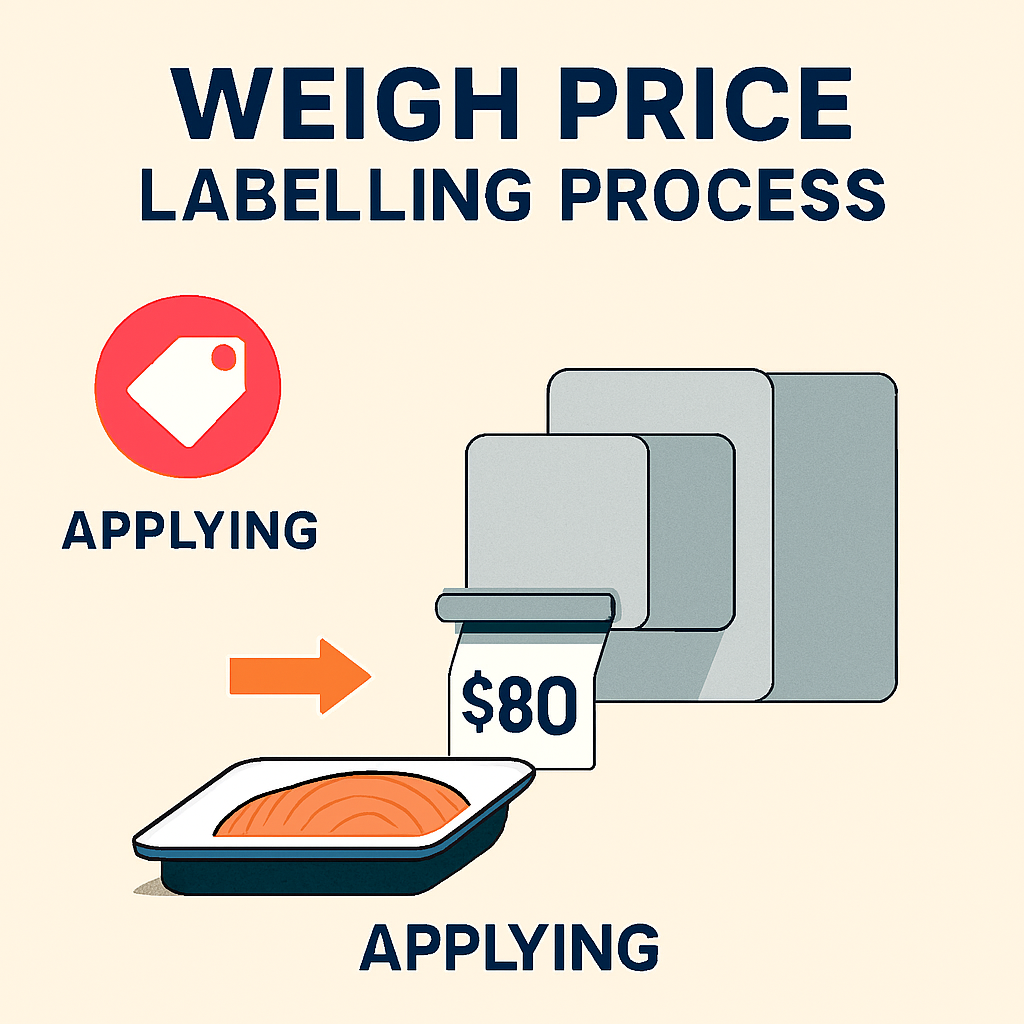

Label Application

The automatic labeling machine applies the label precisely—whether on the top, side, or corner of the product. Options like blow-on or tamp applicators ensure adhesion without slowing the line. The whole process occurs on one conveyor, minimizing footprint and maximizing efficiency.

This integrated approach solves practical issues like label mismatches or downtime from manual swaps. In one client setup, we reduced changeover time from 30 minutes to under 5 by enabling one-touch template downloads via the HMI (Human-Machine Interface).

Efficiency Gains and Real-World Benefits

Adopting a weigh price labeling system isn't just about automation—it's about tangible results. Based on our installations, clients see throughput increases of 15-30%, as manual labeling crews are replaced by reliable machines. For a mid-sized beverage line handling 12,000 units per hour, this meant ditching 6-8 workers per shift while syncing perfectly with upstream filling processes.

Accuracy skyrockets too, with error rates dropping below 0.1%. By pulling variable data directly from your database, the system avoids human mistakes like wrong batch codes or dates. Plus, built-in vision checks downstream verify label quality, rejecting defects in under 50ms to maintain 99.5% pass rates.

Cost savings are another highlight. Switching to blank label rolls cuts inventory needs by 40%, merging multiple pre-prints into one versatile stock. Traceability improves dramatically—each label ties back to production details, meeting standards for food and pharma tracking. Our clients in flexible manufacturing love the quick changeovers, supporting small-batch, multi-variety runs without headaches.

Don't forget scalability: Our systems include redundant ports for IoT integration, allowing remote monitoring of metrics like OEE (Overall Equipment Effectiveness) and MTBF (Mean Time Between Failures). This proactive approach prevents downtime, keeping your line humming.

Integration Tips for Your Production Line

Integrating a weigh price labeller doesn't require a full overhaul. We follow a straightforward "data docking—mechanical synchronization—closed-loop control" method, drawing from our extensive experience.

Start with needs assessment: Define your throughput (e.g., pieces per minute), label positions, and data sources. Match interfaces with existing equipment—our systems support common protocols and I/O triggers for easy upstream/downstream syncing.

Hardware setup is plug-and-play: Mount the unit beside your conveyor with minimal modifications. Key parameters like line speed and product spacing ensure a labeling window of at least 0.3 seconds. For longer reaches, add servo arms or slides.

Data linkage is key: Connect to your ERP for order details, with real-time feedback for tracing. The PLC generates a "product in place" high-speed pulse or EtherCAT distributed clock synchronization signal to ensure that the error from printing completion to labeling is ≤ ±1 mm.

Add closed-loop features: Install vision downstream for barcode grading, triggering rejects if needed. Pre-plan for harsh environments with IP54 protection against dust or moisture.

Finally, test rigorously—run for 2 hours initially, then 72 hours for stability. Our team at SameGram handles this end-to-end, ensuring seamless embedding without disrupting output.

For more on integrating with checkweigher metal detector combinations or other setups, visit our Solutions Page.

Why Choose SameGram for Your Weigh Price Labeling Needs

At SameGram, we're not just suppliers—we're partners in your success. With over a decade in precision weighing and labeling, Our Factory produces robust, customizable systems tailored to your specs. From our About Us Page, you'll see our commitment to quality: ISO-certified processes, in-house R&D, and global support.

Our weigh price labeller lineup, detailed on the Product Page, features models with advanced rejectors, flexible conveyors, and integration-ready designs. We've empowered businesses worldwide to achieve "efficiency + quality + traceability" gains. Ready to upgrade? Contact Us for a free consultation—we'll show how our systems can transform your line.

Conclusion

Streamlined production with weigh price labeling systems is the smart way forward, cutting costs while enhancing reliability. By automating the weigh-print-apply cycle, you solve everyday challenges like errors and slowdowns, positioning your operation for growth. At SameGram, we're here to make it happen. Explore our full range today and take the first step toward optimized manufacturing.

Hot-Sale Weigh Price Labeler

SCL-10060L50 is an automatic weigh price labeler with scanning, weighing scale label printing, and template customization.

SCL-8050L30 is an advanced automatic price weigh label machine with dynamic weighing, label editing, and MES/ERP integration.

SCL-7035L5 is a weigh price labeler that integrates a weighing machine with label printer(s),which is very widely used

SL-V is a smart labeller with custom label printing, vision labeling, and real-time weight binding for post-pack inspection.

SL is an automatic labeling machine supports fast, precise labeling. Ideal automatic labeling machine for box dynamic labeling