Best Practices for Implementing and Maintaining Industrial Metal Detectors

- Share

- Issue Time

- Aug 12,2025

Summary

Learn how to implement, calibrate, and maintain industrial metal detectors for food and pharma. Improve HACCP/BRC compliance and reduce false rejects.

Best Practices for Implementing and Maintaining Industrial Metal Detectors

Industrial metal detectors are essential tools in ensuring product safety and quality during manufacturing processes, particularly in industries like food production, pharmaceuticals, and chemicals. These devices detect metallic contaminants such as iron, stainless steel, aluminum, and other metals that could pose risks to consumers or damage equipment. For instance, in food production, metal detectors help identify metal fragments in products, preventing recalls and ensuring compliance with safety standards like HACCP, IFS, BRC, and FSMA.

As a leading provider of intelligent weighing and inspection solutions, SameGram specializes in high-performance metal detectors designed for seamless integration into production lines. With over 20 years of expertise and more than 5,000 units delivered worldwide, SameGram's metal detectors, such as the DD-720 and DD-360 Series, offer advanced multi-frequency technology for superior sensitivity and reliability. Explore our metal detector offerings to see how we can safeguard your operations.

Key Benefits of Implementing Multi-frequency Metal Detectors in Your Production Line

Implementing metal detectors not only protects against contamination but also optimizes efficiency by reducing downtime and waste. Key benefits include:

● Enhanced Food Safety: Detects even minute metal particles in liquids, pastes, powders, and packaged goods, minimizing health risks.

● Compliance and Quality Assurance: Meets regulatory requirements in the pharmaceutical and food industries, supporting traceability through data logging.

● Cost Savings: Prevents equipment damage and product recalls, with AI-based systems reducing false rejections.

SameGram's metal detectors excel in these areas, featuring foil-compatible detection and IP65-rated protection for harsh environments. Our systems have helped clients like food processors reduce false alarms by 85% and improve detection accuracy to 99.8%, as seen in real-world case studies.

Customizable metal detector for conveyor belt with dual frequency, high sensitivity, and strong anti-interference.

Categories: Metal Detector

Brand: SameGram

Model: DD-390 Series

Sensitivity (empty belt surface): FE(Φ0.8mm),NON-FE(Φ1.2mm),SUS316(1.5Φmm)

Production speed: 1~1000m/min, fixed speed 25/min

Effective detection channel(mm): 400 ×120 (W×H) customizable

Conveyor belt material: Food-grade PU belt

Structure: SUS304, Comply with HACCP, GMP, FDA, CAS, and other

Protection: IP 66 (probe), Others are IP54, optional

Best Practices for Implementing Dual-frequency Industrial Metal Detectors

Proper implementation ensures maximum effectiveness. Follow these steps to integrate metal detectors into your production line:

1. Assess Your Production Needs

Evaluate your product types (e.g., bulk goods, liquids, or packaged items) and potential contaminants. For food safety, consider product effects like moisture or metallic packaging that could interfere with detection.

● Tip: Use multi-simultaneous frequency technology to handle varying product effects. SameGram's DD-390 Series, with sensitivities as low as Fe ≥0.8mm, is ideal for high-speed lines up to 1000m/min.

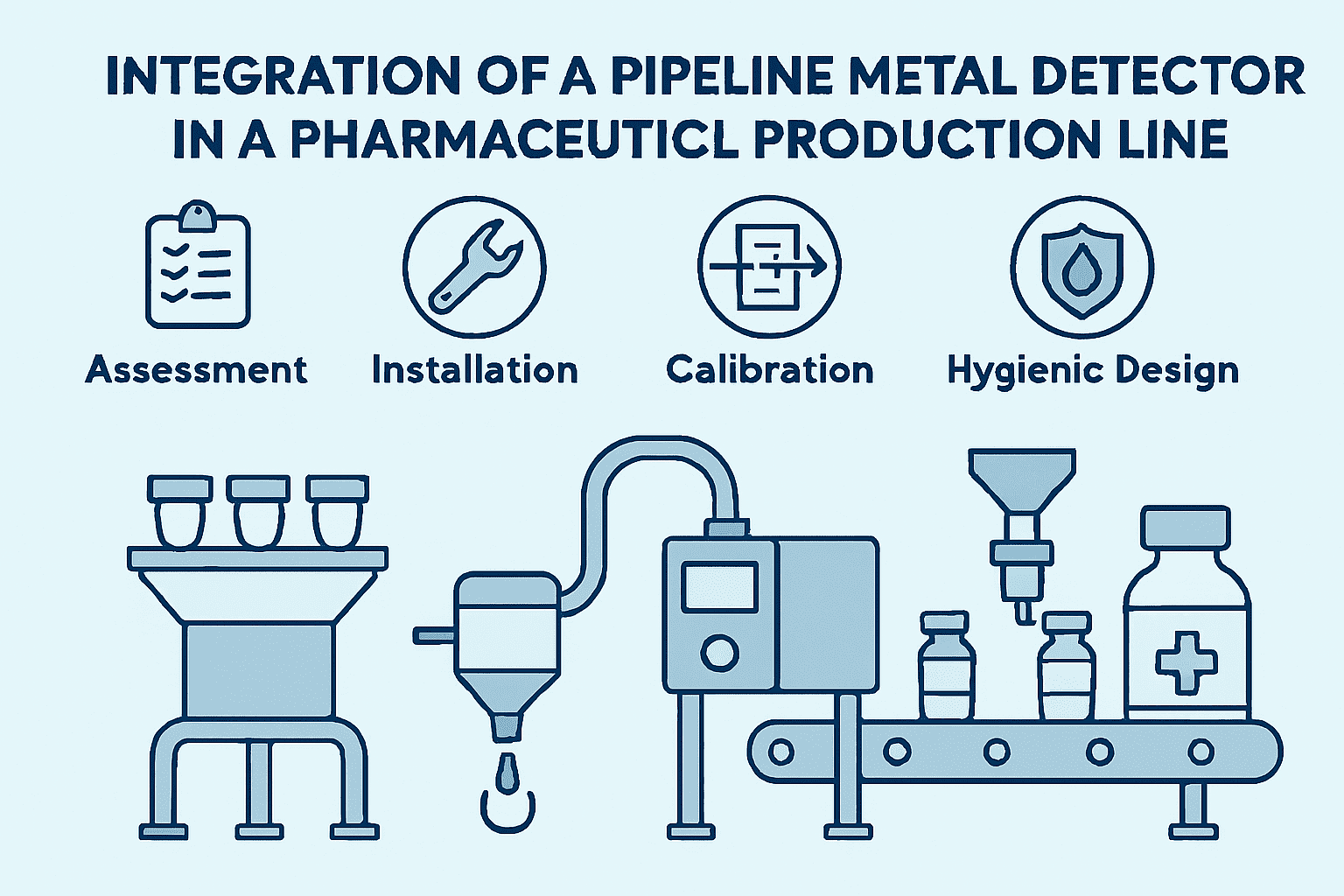

2. Choose the Right Type of Metal Detector

Select based on application:

● Tunnel/Conveyor Detectors: For piece goods on belts.

● Pipeline Detectors: For liquids and pastes in food or pharma lines.

● Free-Fall Detectors: For powders and granules.

SameGram offers customizable options, including combination systems that integrate metal detection with checkweighing.

3. Integrate with Existing Systems

Ensure seamless integration:

● Synchronize with conveyor speeds and rejection mechanisms (e.g., air jets, pushers).

● Use modular designs for easy installation in conveyors, chutes, or pipelines.

● Implement AI for reducing false positives in challenging products like brined items.

4. Set Sensitivity and Frequencies

Understanding frequencies is crucial:

● Lower frequencies detect stainless steel better in conductive products.

● Higher frequencies suit non-ferrous metals.

● Use "Product Teach" mode to auto-adjust settings.

SameGram's dual-frequency technology ensures optimal performance across materials, aligning with best practices for sensitivity without compromising speed.

5. Validate and Test

Conduct initial validation with test pieces to confirm detection limits. Document results for compliance.

By following these practices, you can resolve common issues like integration disruptions or inaccurate detection, enhancing overall production reliability.

Regular maintenance extends equipment life and maintains accuracy. Here's how to keep your metal detectors performing optimally:

1. Routine Inspections and Cleaning

● Perform daily visual checks for damage, loose connections, or wear.

● Clean with FDA-approved agents, especially in food/pharma settings, to prevent buildup.

● Sanitize components like coils and reject systems weekly or based on usage.

SameGram's hygienic, easy-to-clean designs minimize downtime, with our 12-month warranty and lifetime support ensuring trustworthiness.

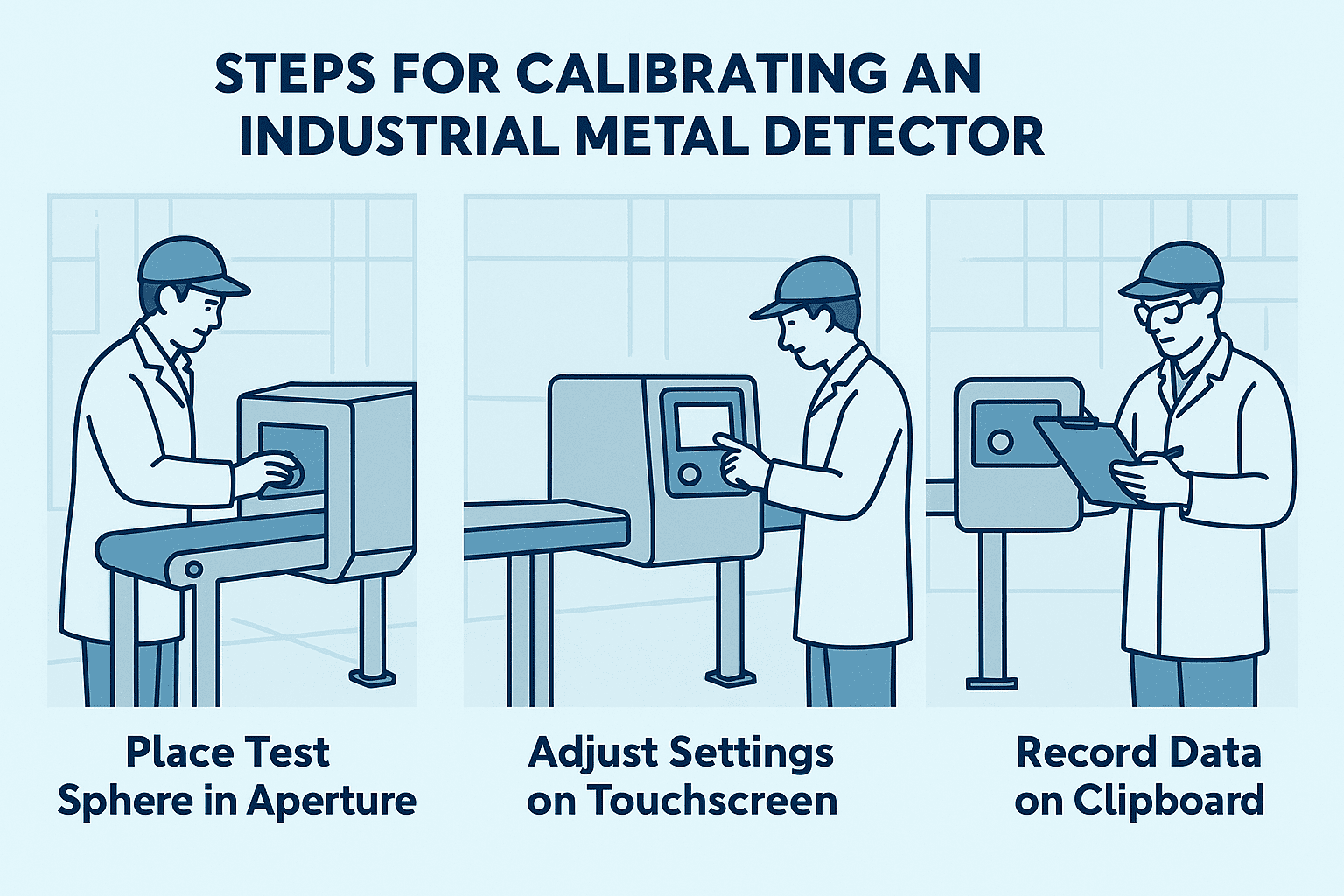

2. Calibration Procedures

● Calibrate monthly or per manufacturer guidelines using certified standards.

● Steps: Clean the system, place test pieces (e.g., Fe 0.5mm spheres), adjust settings, verify, and log results.

● Frequency: Increase in harsh environments or high-usage scenarios.

SameGram provides free sample testing and remote diagnostics to simplify calibration, helping you meet standards like GMP and HACCP.3. Troubleshooting Common Issues

● False Alarms: Check for electromagnetic interference; shield and ground the system.

● Reduced Sensitivity: Inspect for wear; replace parts like coils using genuine components.

● Environmental Factors: Monitor temperature/humidity; use IP-rated models for stability.

Our systems include robust data logging for quick issue identification, reducing troubleshooting time.

4. Documentation and Training

● Maintain logs of maintenance, calibrations, and detections for audits.

● Train staff on operation and preventive care to ensure consistent performance.

SameGram offers comprehensive online training and on-site demonstrations, drawing from our expertise.

5. Periodic Upgrades and Audits

● Update software for improved algorithms.

● Conduct annual audits to assess compliance and efficiency.

These maintenance practices address real-world problems like downtime or non-compliance, ensuring long-term reliability.

How SameGram Supports Your Metal Detection Needs

At SameGram, we are committed to delivering innovative, sustainable solutions that align with industry best practices. Founded with a focus on automation, our R&D team develops modular systems that reduce waste and energy use while meeting global standards. Whether you're in food processing or pharmaceuticals, our metal detectors provide the expertise and reliability you need.

Contact us for customized advice or a free consultation. Discover how SameGram can elevate your production safety today.

Conclusion

By implementing and maintaining industrial metal detectors following these best practices, you can significantly enhance product safety, reduce risks, and optimize operations. Partnering with an experienced provider like SameGram ensures access to cutting-edge technology and expert support. Ready to implement? Explore our full range.