Automatic Weigh Price Labellers for Retail Fresh Foods | SameGram

- Share

- Issue Time

- Sep 29,2025

Summary

Discover SameGram's automatic weigh price labellers for efficient retail fresh food packaging. Integrate checkweighers for precise labeling of meat, fish, fruits & veggies—boost accuracy, cut costs, and streamline operations today.

In the fast-paced world of retail fresh foods, where accuracy and efficiency can make or break your bottom line, automatic weigh price labellers have become essential tools. These systems handle everything from fresh meat and fish to fruits and vegetables, ensuring that each product is weighed, priced, and labeled correctly right on the production line. At SameGram, we've been perfecting these solutions for over 20 years, helping businesses like yours deliver high-quality, compliant products to customers without the hassle of manual processes.

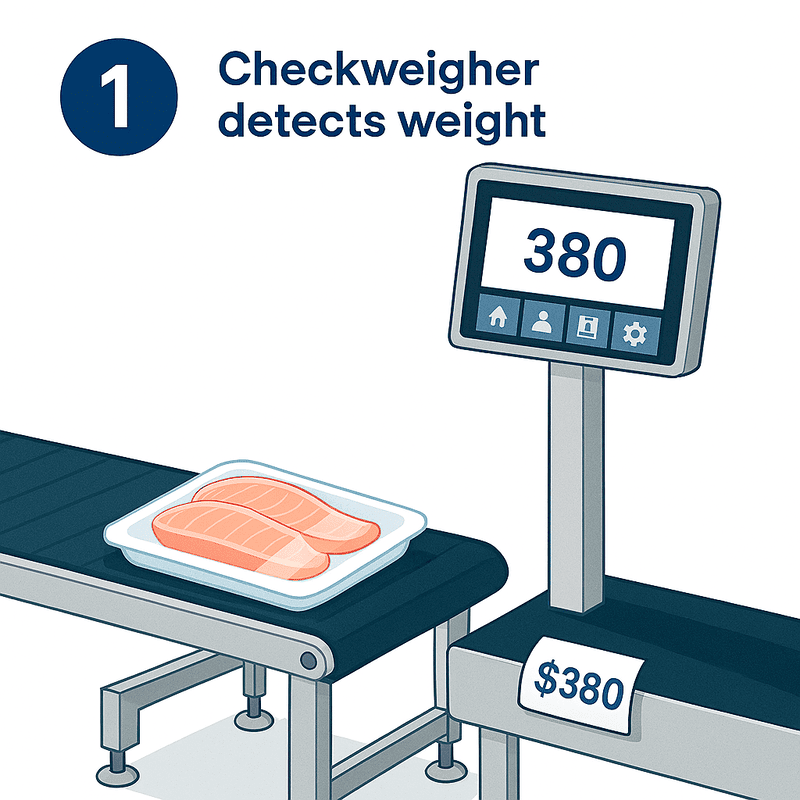

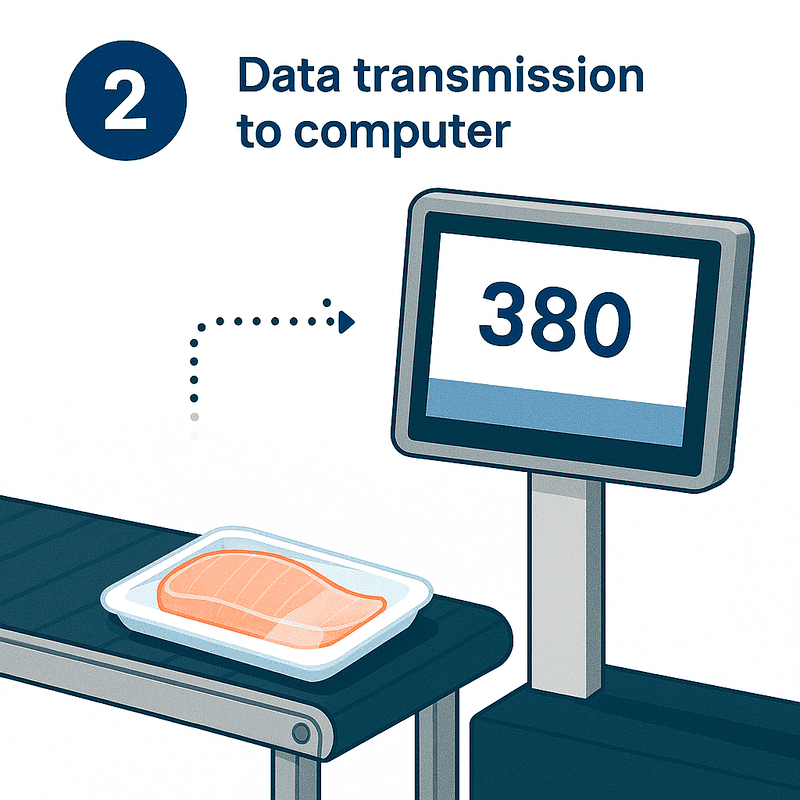

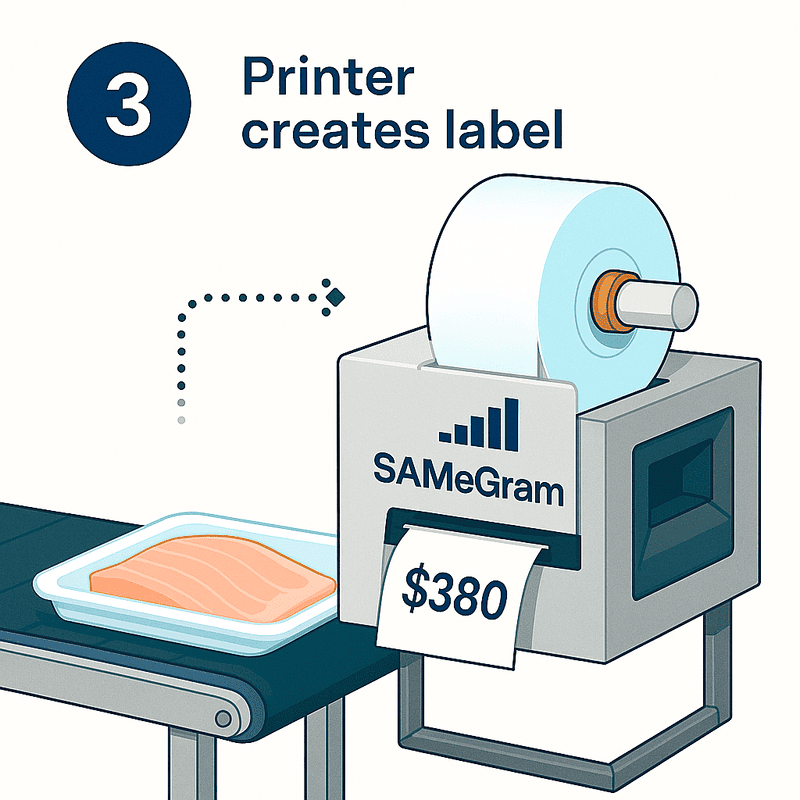

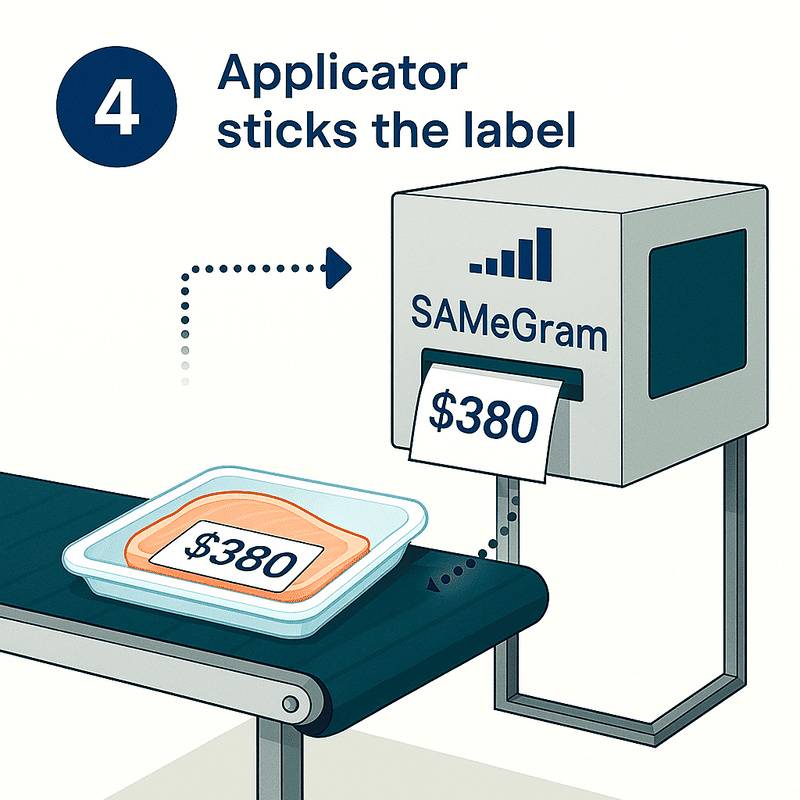

Imagine a busy supermarket backroom or a warehouse packing line where items like juicy steaks, fresh salmon fillets, ripe apples, or crisp lettuce heads move seamlessly along a conveyor belt. The weigh price labeller kicks in: it first checks the weight using an integrated checkweigher system, transmits that data instantly to a computer, prints a custom label with the exact weight, price, and other details, and applies it—all in one smooth operation. This isn't just about speed; it's about solving real-world problems like inconsistent pricing, labeling errors, or wasted time that can lead to unhappy customers and lost revenue.

As a high-tech enterprise specializing in industrial automation weighing systems, SameGram has built a reputation for delivering precise, efficient, and reliable solutions. With more than 20 years of experience, we've supplied over 5,000 units to clients in over 60 countries, focusing on industries like food processing, pharmaceuticals, and logistics. Our mission is simple: to make your operations smarter and safer by creating automated systems that boost efficiency and ensure product consistency.

Our state-of-the-art 4,000+ square meter factory is equipped with advanced bending machine, laser cutting, and precision testing facilities. We adhere to strict quality controls, including CE and ISO9001 certifications, and conduct multi-stage inspections like IQC, PQC, and FQC to guarantee every system meets global standards. Whether you're dealing with perishable fresh foods or high-volume retail packaging, SameGram's in-house manufacturing ensures rapid delivery and customization tailored to your needs.

We're not just manufacturers—we're innovators. Our R&D team invests in cutting-edge technologies like AI-assisted inspections and Industry 4.0 integrations, allowing seamless connections to your MES or ERP systems. And with services like free sample testing, on-site demonstrations, and lifetime technical support, we're committed to your success. Ready to upgrade your line? Contact us today at SameGram.com for a personalized consultation and see how our automatic checkweigher with labeller system can transform your business.

Core Applications: How Weigh Price Labellers Integrate for Real-Time Efficiency

Weigh price food labeling system shine in retail fresh food environments by combining checkweighing, data transmission, printing, and application into a single streamlined process. Picture this: a product enters the system on a conveyor belt. The dynamic checkweigher accurately measures its weight in real-time—handling ranges from 1g to 50kg depending on your setup—then sends that info directly to the labeling unit. The printer generates a label with precise details like weight, price per unit, total cost, best-by date, or even cooking instructions based on the item's size.

This integration is perfect for fresh meats, where variable weights mean fixed pricing won't cut it, or delicate fish that require hygienic handling to avoid contamination. For fruits and vegetables, it ensures labels stick securely without damaging the produce, all while maintaining high speeds to keep up with peak-season demands. SameGram's Checkweigher with Labeller Combination System, like our Automatic Weigh Price Labeler with Real-time Weight & Custom Label Printing SCL-7035L5 model, exemplifies this: it weighs items up to 5,000g with ±0.5-2g accuracy, labels at 15-50 pieces per minute, and integrates metal detection for added safety—ideal for spotting contaminants in bulk veggie packs.

In practice, this solves common pain points. For instance, in a fresh vegetable packaging operation near Ho Chi Minh City, our system boosted efficiency by achieving 99.9% label accuracy, reducing errors that could lead to recalls or customer complaints. It's all done on one conveyor, minimizing space and labor needs while ensuring traceability from farm to shelf.

Key Features and Technical Specs: Designed for Precision and Versatility in Food Labeling Machines

SameGram's automatic weigh price label systems are engineered with food-grade stainless steel for ultimate hygiene, featuring IP65–IP69K protection to withstand washdowns in wet or dusty settings. They handle both random and fixed weights effortlessly, with print-and-apply functionality that supports thermal printing for durable labels—think barcodes, QR codes, batch numbers, and more.

Take our core automatic meat labeling machine models: they achieve labeling speeds up to 60 pieces per minute with ±2mm application accuracy and ±2g weighing precision. The modular design allows easy upgrades, like adding vision checks or barcode scanners, and supports belt speeds of 5-28m/min. Whether you're labeling top, side, or wraparound on irregularly shaped items like whole chickens or bundled berries, the servo-controlled applicators adjust automatically.

For heavier loads, options like the Advanced Checkweigher with Labeller Combination System SCL-10060L50 cover 10g-50kg with 15-25 pieces per minute labeling, making them versatile for everything from small fruit trays to large meat cuts. All systems sync real-time data to prevent mismatches, ensuring compliance with standards like HACCP and FDA. Plus, with Ethernet, RS232, and USB interfaces, they plug right into your existing setup for full traceability.

These specs aren't just numbers—they address real issues. If your line struggles with variable weights causing pricing discrepancies, our systems eliminate that by binding weight data directly to labels, cutting down on rework and waste.

SCL-10060L50 is an automatic weigh price labeler with scanning, weighing scale label printing, and template customization.

Categories: Checkweigher Combination System

Trademark/Brand: SameGram

Model: SCL-10060L50

Weighting range: 10-50g

Weighting accuracy: ±0.5-2g

Labeling speed: 15-25pcs/min

Labeling accuracy: ±5-10mm

Weighting section size: L 500mm*W 300mm

Applicable product size: L≤300mm; W≤300mm

Benefits: Boost Your Bottom Line with Smarter Operations

Investing in an automatic weigh price labeller from SameGram pays off quickly through cost savings and improved workflows. By automating the entire weigh-print-apply sequence, you slash labor costs—no more teams manually weighing and sticking labels, which can eat up hours in a high-volume retail setup. Packaging expenses drop too, as precise industrial automation weighing labeling reduces overfills and underfills, optimizing material use for fresh foods that spoil quickly.

Efficiency skyrockets: our systems have helped clients increase line speeds by up to 40% while cutting false rejects by 68%, as seen in pharmaceutical integrations that mirror fresh food challenges. For retail, this means fresher products on shelves, fewer errors leading to returns, and better inventory management through traceable data.

Hygiene and compliance are non-negotiable in fresh foods, and our ultra-hygienic designs meet GMP/ISO standards, preventing cross-contamination in meat or fish processing. Sustainability wins as well—less waste from accurate portions aligns with ESG goals, helping you appeal to eco-conscious consumers. Overall, these benefits translate to higher customer satisfaction, stronger market position, and a reliable ROI.

To get the most from your system, start with proper installation: position it in a clean, well-ventilated area and integrate it early in your line design for smooth flow. Regular calibration—every shift or as per your protocols—keeps accuracy spot-on, especially for variable-weight items like seasonal fruits.

Train your team on the touchscreen interface; it's intuitive, but knowing how to switch recipes quickly (e.g., from veggies to meats) saves time. Monitor data logs via connected software to spot trends, like recurring overweight issues, and adjust upstream processes accordingly.

For warehouse ops, pair with rejection mechanisms to auto-sort non-compliant items, minimizing downtime. In-store, use compact models to fit tight spaces while maintaining speed. Finally, schedule preventive maintenance—our lifetime support includes remote diagnostics to catch issues early.

By following these tips, you'll resolve bottlenecks, extend equipment life, and keep your fresh food operations running like clockwork.

Ready to Elevate Your Retail Fresh Food Packaging?

Weigh price labeling equipment aren't just machines—they're game-changers for handling fresh meat, fish, fruits, and vegetables with precision and ease. At SameGram, our solutions are backed by decades of expertise, rigorous quality, and a customer-first approach. Don't let outdated processes hold you back. Visit SameGram today to Explore Our Full Range of Weighing, Metal Detecting, and Labeling Solutions. Request a free demo or customize a system that fits your needs perfectly. Let's weigh, price, and label your way to success!

Hot-Sale Food Labeling Machine

SCL-7035L5 is a weigh price labeler that integrates a weighing machine with label printer(s),which is very widely used

SCI is an automatic Checkweigher integrates industrial inkjet printer for real-time checkweighing and inkjet printing.

SCL-10060L50 is an automatic weigh price labeler with scanning, weighing scale label printing, and template customization.

SCL-8050L30 is an advanced automatic price weigh label machine with dynamic weighing, label editing, and MES/ERP integration.