End of Line Conveyor Metal Detection System DD-360 Series

- Model

- DD-360 Series

Item specifics

- Passing height

- 80~1000 (customizable)

- passing width

- 300~1200 (customizable)

- Standard detection sensitivity: iron(ΦMM)

- ≥0.6

- Standard detection sensitivity: non-iron(ΦMM)

- ≥0.8

- Standard detection sensitivity: SUS304(ΦMM)

- ≥1.2

- Protection Level

- IP67

Review

Description

Detail Information

End of Line Conveyor Metal Detection System DD-360 Series

Introduction

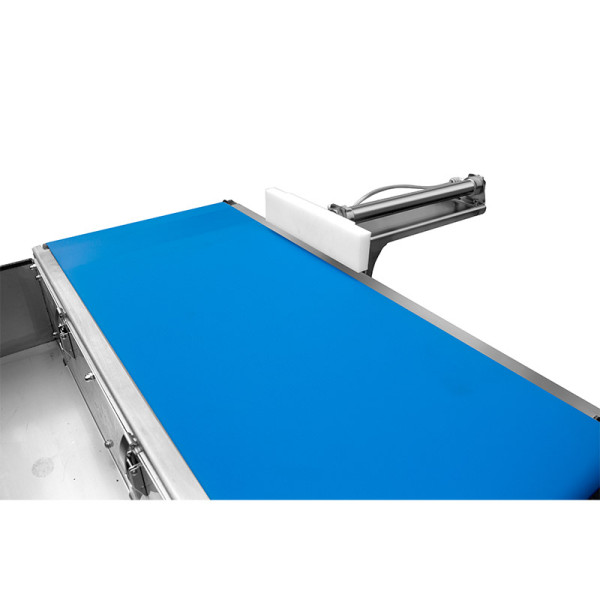

Samegram’s DD-360 Series is an end-of-line industrial metal detector conveyor engineered for manufacturers that require stable, high-sensitivity inspection with minimal operator effort. Its touch-screen interface simplifies product setup, allowing quick parameter adjustment and reliable calibration for items with different characteristics. The dual-CPU digital system automatically identifies optimal detection points, improving sensitivity and consistency even when products contain moisture, salt, or temperature variations.

Operators can view real-time signal strength, operating status, and fault diagnostics directly on the built-in waveform display, making maintenance faster and more intuitive. The system supports multi-frequency detection and stores over 100 product profiles to enable rapid product changeovers on busy lines. Detection logs and operational data can be exported via USB for traceability and compliance.

With adjustable conveyor speed, user-level access control, and multiple reject options, the DD-360 adapts easily to modern automated packaging environments. Its IP67 dust- and water-resistant structure ensures stable performance in harsh conditions. Compliant with GFSI and FSMA requirements, this food-grade metal detector minimizes false rejects, reduces waste, and supports stronger brand protection for food, pharma, and chemical producers.

End of Line Conveyor Metal Detection System DD-360 Series

Features

End of Line Conveyor Metal Detection System DD-360 Series

Technical Parameters

| Product model | DD-360 series | |||||

| Passing height | 80~1000 (customizable) | |||||

| passing width | 300~1200 (customizable) | |||||

| Standard detection sensitivity | FE(ΦMM) | ≥0.6 | ||||

NON-FE(ΦMM) | ≥0.8 | |||||

SUS304(ΦMM) | ≥1.2 | |||||

protection level | IP67 | |||||

Memory product quantity | 100 kinds | |||||

Display mode | LED LCD | |||||

Operation mode | Touch button input (touch optional) | |||||

Alarm mode | Alarm shutdown, buzzer alarm, or rejection mechanism are optional. | |||||

Machine material | The entire machine is made of carbon steel with baked enamel or 304 stainless steel, and complies with HACCP, GMP, CAS and other standards. | |||||

Machine weight | ≥120KG | |||||

power supply | AC200V±10% 50-60HZ (AC110V or AC380V can be customized) Other options available | |||||

Usage environment | Temperature: -180~50℃, Relative Humidity: 30~90℃ | |||||

Available Rejection Systems for End of Line Conveyor Metal Detection System DD-360 Series

Fast swing arm works with checkweigher or metal detector systems to remove defective boxes and bags up to 1 kg.

Samegram’s Belt Drop rejector is a high speed rejector using pneumatic lift rods to gently remove thin bags and flat products.

The heavy-duty pusher rejector pair with checkweigher systems to deliver accurate, mid-speed removal of heavy, boxed items.

* Probe detection window, the size of the whole machine can be customized according to customer needs. The higher the detection window height, the lower the detection sensitivity. At the same time, the wider the detection window, the lower the detection sensitivity

* The detection sensitivity is the detection sensitivity obtained by placing the detection card in the center of the conveyor belt and passing it through the detection channel. The actual detection sensitivity will vary depending on the product being tested or the conditions of use.

* The detection sensitivity is the detection sensitivity obtained by placing the detection card in the center of the conveyor belt and passing it through the detection channel. The actual detection sensitivity will vary depending on the product being tested or the conditions of use.

File Downloads

For more product related parameter files, please contact us.

End of Line Conveyor Metal Detector DD-360 Series Applications

Packaged Bread

Inspects small packaged bread for metal contamination during final packaging to ensure consumer product safety.

Detects tiny metal particles in chocolate bar production lines, preventing contamination before final sealing.

Mini Biscuits

Screens mini biscuit packs for metallic foreign objects post-baking, ensuring safe delivery to retailers.