How Dynamic Checkweighers Work: Precision in Motion

- Share

- Issue Time

- Jan 3,2022

Summary

This article introduces the working process of a dynamic checkweigher, highlighting its high-speed, precise, and automated operation. It explains how the system detects product weight in real time, eliminates non-compliant items, and supports production data analysis—enhancing efficiency and quality control across industries like food, pharmaceuticals, and chemicals.

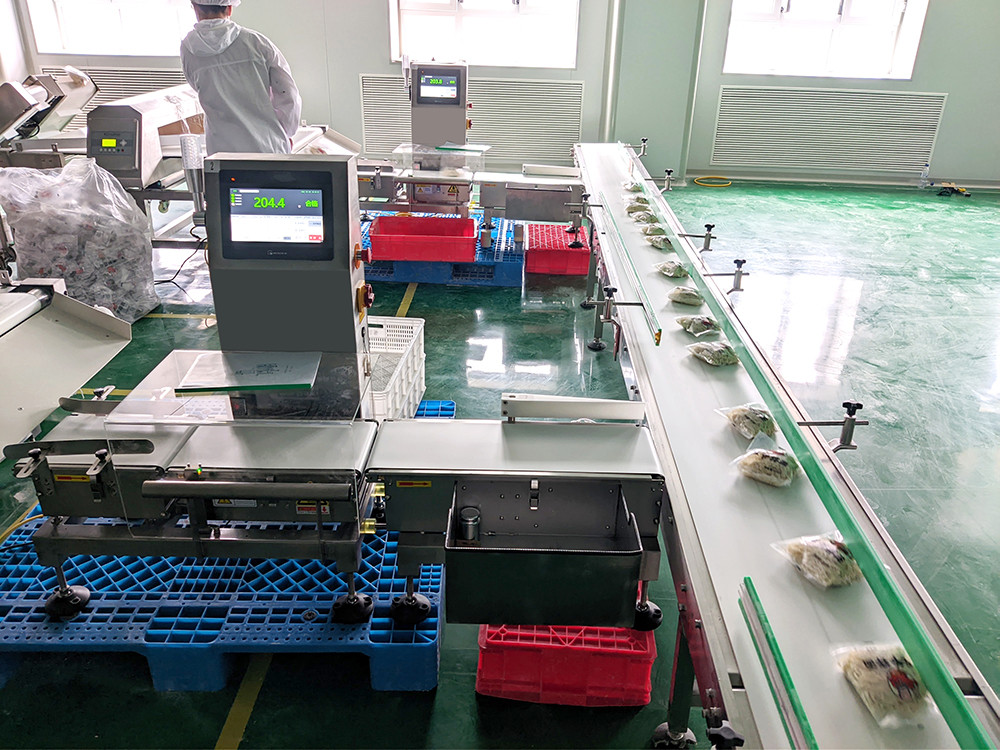

As industrial automation and smart manufacturing continue to evolve, product inspection and sorting on production lines are undergoing significant technological upgrades. Among the innovations, dynamic checkweighers have emerged as essential equipment in industries such as food, pharmaceuticals, and chemicals, thanks to their high speed and precision.

The working principle of a dynamic checkweigher is rooted in electromagnetic induction and advanced sensor technology. When a product moves onto the weighing section of the conveyor, load cells beneath the conveyor detect the slight pressure caused by the item. These changes are converted into electrical signals and transmitted in real time to the weighing controller—the core of the system.

Equipped with a high-performance processor and algorithms, the controller analyzes these signals to calculate the product's exact weight. It then compares this result against predefined acceptable weight limits. This process happens almost instantaneously, ensuring continuous, high-efficiency operation on the production line.

If a product does not meet the weight requirement, the controller sends a signal to the reject system—such as a pusher or air jet—to remove the non-compliant item from the line. This guarantees that only qualified products proceed to the next stage, securing product quality and consistency.

In addition to real-time weighing and rejection, modern dynamic checkweighers feature data storage and analytics capabilities. Each measurement is saved for traceability and performance analysis, helping businesses gain insights into production trends, optimize processes, and improve overall efficiency.

Dynamic checkweighers also reduce reliance on manual labor, minimize human error, and improve product pass rates. By integrating with ERP, MES systems, they form part of a broader intelligent manufacturing ecosystem—enabling real-time monitoring, smart decision-making, and automated control.

As technology advances, dynamic checkweighers will play an even more crucial role in future production lines, working seamlessly with other automated systems to build smarter, faster, and more efficient factories.