Automated Weighing + Real-Time Labeling: Achieving Smart, Integrated Checkweigh and Label Solutions

- Share

- Issue Time

- May 9,2024

Summary

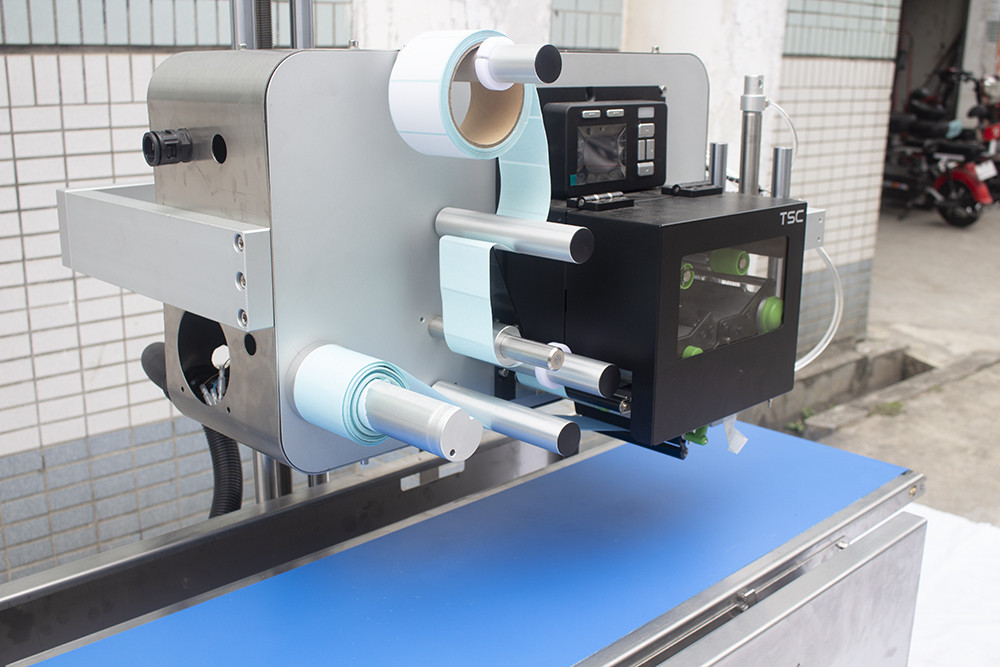

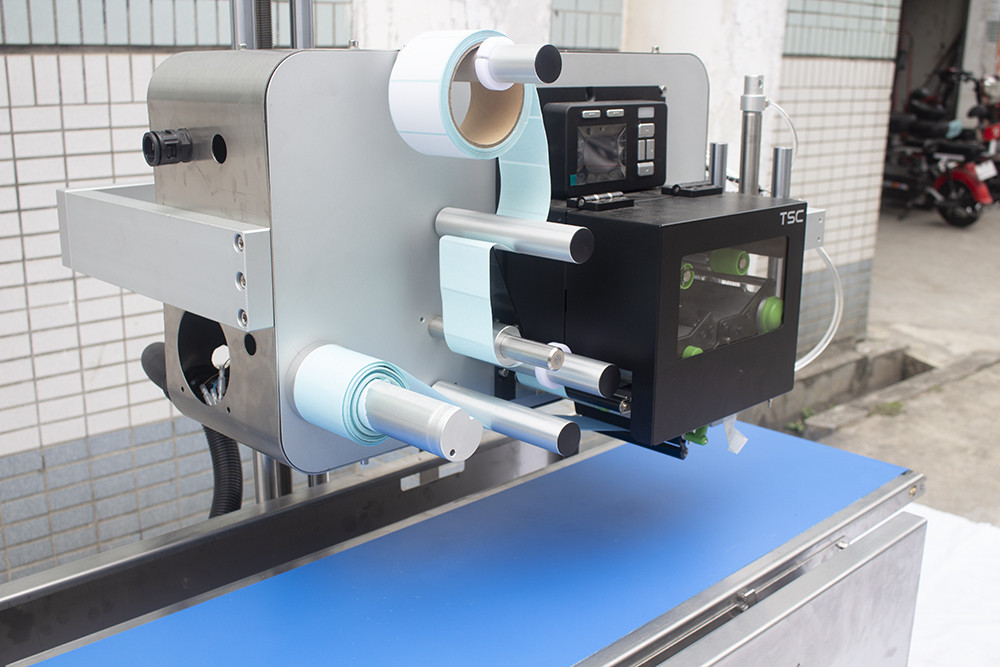

SameGram has launched an integrated solution that combines automatic weighing and real-time label printing into one smart system. Designed to boost efficiency and reduce manual error, it enables seamless checkweighing and labeling in high-speed production lines. The system supports data integration with ERP/MES platforms, offering enhanced traceability and intelligent production management.

As industrial automation accelerates across manufacturing and logistics, the demand for integrated, intelligent systems continues to grow. SameGram has introduced a smart solution that combines high-precision automatic weighing with on-the-spot label printing, enabling a seamless one-stop process for checkweighing and labeling.

This advanced system is equipped with accurate sensors and a real-time data processing unit that ensures each item is weighed quickly and precisely. As soon as the weight is confirmed, a label is generated and applied immediately—automatically linking product information to the packaging flow. This integration significantly reduces manual handling and errors common in traditional setups.

Designed for high-speed production environments, the system offers:

· Faster throughput with consistent weighing accuracy

· Fully automated label application

· Reduced labor dependency and human error

· Real-time communication with ERP, MES systems

By integrating with existing production lines, it provides valuable weight and traceability data for quality control and logistics tracking, helping managers optimize output while maintaining strict compliance.

This checkweigh-label combo unit is ideal for industries such as food packaging, pharmaceuticals, cosmetics, electronics, and logistics—where speed, accuracy, and product traceability are critical.

SameGram continues to develop next-generation automation equipment tailored to industry needs. With this integrated weighing and labeling solution, businesses can now move toward smarter, faster, and more reliable production lines.