Precision & Purity: How Washdown Checkweighers Elevate Food Safety and Regulatory Compliance

- Share

- Issue Time

- Jul 29,2025

Summary

In the highly regulated food industry, precision and hygiene are not just good practices—they are legal mandates. This blog post delves into the critical role of washdown checkweighers in ensuring stringent regulatory compliance and maintaining impeccable food safety standards. Learn how washdown checkweighers boost food safety and compliance. Discover Samegram’s precision solutions for hygiene and efficiency in food manufacturing.

In today's fast-paced and highly regulated food industry, ensuring product safety and compliance is critical. Manufacturers must meet stringent standards like HACCP, FSMA, and global regulations to protect public health and maintain consumer trust. Failure to comply can lead to foodborne illnesses, costly recalls, financial penalties, and reputational damage. Enter the checkweigher—a vital tool in food processing, with washdown models playing a starring role in maintaining hygiene and accuracy.

This article dives into how washdown checkweighers ensure food safety, meet regulatory demands, and boost operational efficiency. We’ll spotlight Samegram, a trusted leader in checkweighing solutions, and show how our products help food manufacturers excel. For more on Samegram’s innovative offerings, visit our product page.

Why Washdown Checkweighers Are Essential in Food Manufacturing

Washdown checkweighers are advanced weighing systems designed for food processing environments. Unlike standard models, they feature robust, hygienic designs and high ingress protection (IP) ratings, enabling them to withstand frequent, high-pressure cleaning. Their core mission? To ensure every product meets precise weight targets while maintaining a sanitary production line.

The Power of Washdown Design

Sanitation is non-negotiable in food production. Equipment must resist contamination risks like bacteria, allergens, and debris. Washdown checkweighers excel here, supporting Good Manufacturing Practices (GMP) with their ability to endure rigorous cleaning cycles. This prevents cross-contamination and keeps your facility compliant.

Weight Accuracy: A Win for Compliance and Profit

Regulatory compliance hinges on accurate product weights. Laws require that labeled weights match actual weights within tight tolerances. Deviations spell trouble:

● Under-filling: Risks fines, non-compliance, and legal action.

● Over-filling: Wastes product, cutting into profits.

Washdown checkweighers deliver real-time weight data, ensuring precision in filling processes. This safeguards consumers and keeps your business compliant and profitable.

Samegram's Precision Edge

At Samegram, our checkweighers are engineered for pinpoint accuracy. Whether it’s fresh produce or packaged goods, our systems help you meet regulations effortlessly. Learn more about our precision solutions on our about us page.

Hygienic Design: The Backbone of Food Safety

A checkweigher's ability to stay clean is its superpower. Washdown models feature:

● Food-grade stainless steel (e.g., 304 or 316L) for durability and easy cleaning.

● Smooth, crevice-free surfaces to prevent microbial buildup.

● Sealed components to protect against water and detergents.

This design aligns with Hazard Analysis and Critical Control Points (HACCP) by eliminating contamination risks, making it a cornerstone of food safety compliance.

Built Tough: IP Ratings and Durability

Washdown checkweighers thrive in harsh conditions, boasting IP ratings like IP65, IP67, or IP69K:

● IP65: Dust-tight, water-jet resistant.

● IP67: Dust-tight, immersion-proof.

● IP69K: Withstands high-pressure, high-temperature washdowns—ideal for meat, poultry, and dairy.

This durability ensures long-term reliability, even with daily intensive cleaning.

Samegram's Rugged Reliability

Samegram's washdown checkweighers are built to last, with top-tier IP ratings for the toughest environments. Check out our durable solutions here.

HACCP Integration: Checkweighers as Critical Control Points

HACCP demands proactive hazard prevention, and washdown checkweighers shine as Critical Control Points (CCPs) for weight accuracy. They monitor weights in real time, triggering instant corrections if limits are breached. This reduces the risk of unsafe products reaching consumers.

Video Demo: Checkweigher in Action

See a Samegram checkweigher at work in our video below. It demonstrates the system sorting fresh food products with precision and hygiene in a real-world setting.

Preventing Recalls and Protecting Your Brand

Recalls—caused by weight errors, contamination, or allergens—can devastate a business. Washdown checkweighers mitigate these risks by:

● Ensuring accurate weights.

● Supporting strict sanitation.

● Acting as a preventive control.

With Samegram's solutions, you can minimize recall risks and protect your brand's reputation. Visit our profile page to see how we prioritize food safety.

Boosting Efficiency with Automation

Checkweighers don't just ensure compliance—they enhance efficiency. Automation eliminates manual errors, speeds up production, and cuts labor costs. Samegram's systems include feedback loops to adjust filling equipment in real time, reducing waste and optimizing throughput.

Smart Tech for the Future

Samegram leads with smart checkweighers featuring IoT for predictive maintenance, advanced sensors, and AI analytics—tools that elevate both compliance and performance.

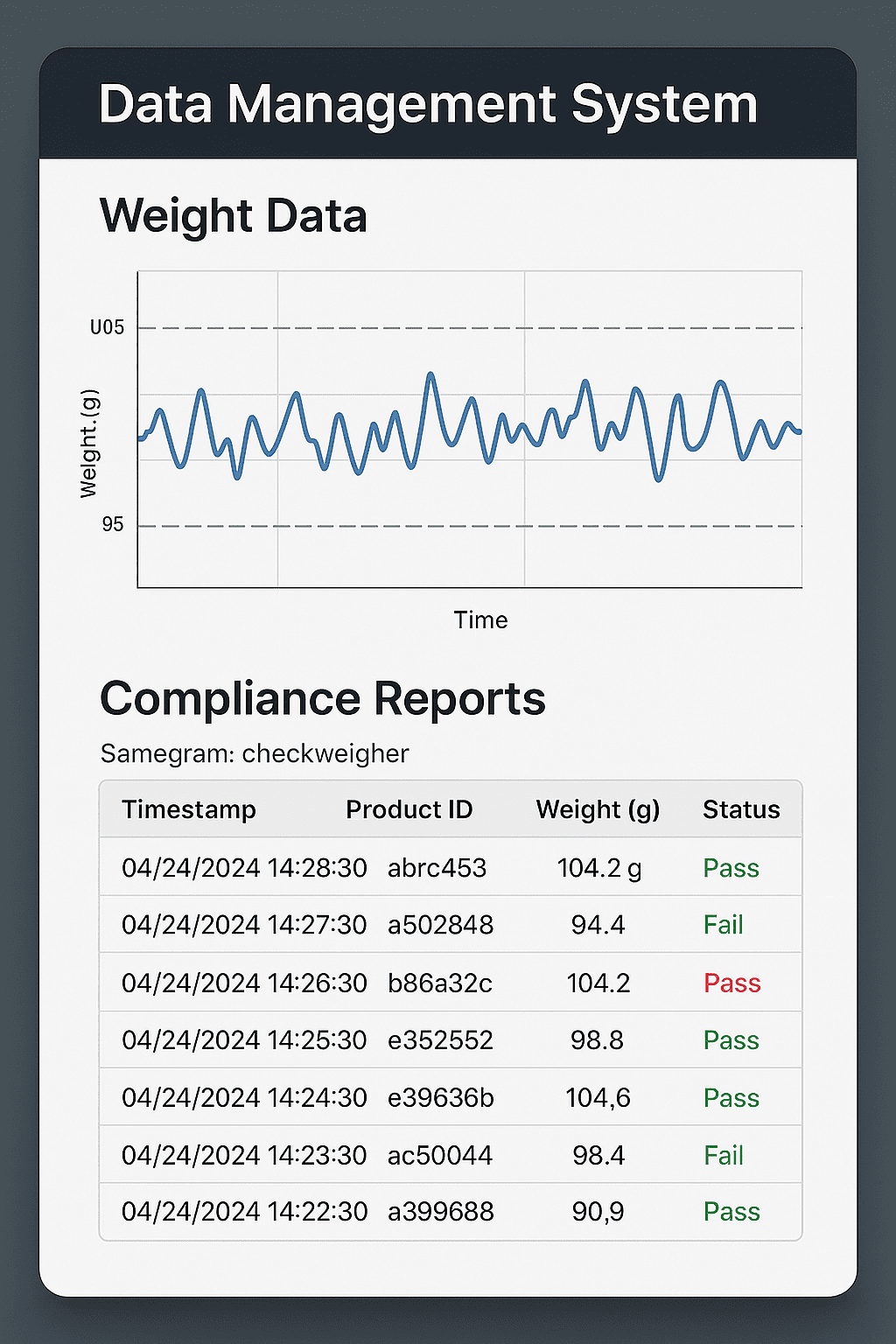

Traceability and Data: Compliance Made Simple

Traceability is a regulatory must. Washdown checkweighers integrate with data systems, logging weight details for audits, quality checks, and recall readiness. Digital records beat manual methods every time, as noted by the FDA’s FSMA guidelines.

Key Benefits of Washdown Checkweighers

| Feature | Food Safety & Compliance Benefit | Operational Benefit | ||

Hygienic Design | Prevents contamination | Cuts cleaning time | ||

Weight Accuracy | Ensures compliance, avoids fines | Reduces giveaway | ||

| Washdown Capability | Meets HACCP/GMP standards | Lowers recall risk | ||

Real-time Data | Enables fast CCP corrections | Optimizes filling | ||

| Robust Construction | Reliable in harsh settings | Minimizes downtime | ||

| Integration | Enhances traceability | Streamlines data management | ||

Conclusion: Trust in Compliance, Trust in Samegram

Washdown checkweighers are indispensable for food safety and regulatory success. They ensure accuracy, hygiene, and efficiency, protecting consumers and brands alike. Samegram delivers industry-leading checkweighers that meet these demands with precision and innovation.

Ready to elevate your food safety game? Explore Samegram’s washdown checkweighers on our product page or contact us today!