Factors Influencing Checkweigher Prices: Key Insights & Buying Guide | Samegram

- Share

- Issue Time

- Aug 16,2025

Summary

Discover the key factors affecting checkweigher prices, from accuracy and speed to integration and materials. Learn how to choose the best inline checkweigher for your food production line to ensure compliance, reduce waste, and optimize costs. Explore Samegram's high-precision solutions today.

As a leading provider of intelligent checkweighing solutions, Samegram specializes in high-precision and ultra-fast checkweighers designed to ensure product weight compliance in factories, particularly for food production. Understanding the factors that influence checkweigher prices is essential for businesses looking to invest in reliable equipment that meets production norms and enhances efficiency. In this comprehensive guide, we'll explore these key factors in detail, drawing on industry expertise to help you make informed decisions. Whether you're in the food, pharmaceutical, or logistics sector, selecting the right in-motion checkweigher can prevent underweight or overweight products, reduce waste, and ensure regulatory compliance.

What is a Checkweigher System and Why Does Price Matter?

A checkweigher system is an automated weighing system used in manufacturing lines to verify if products meet specified weight requirements. It plays a critical role in quality control, especially in food production, where it ensures items like packaged goods comply with design standards and regulations such as FDA or ISO guidelines. By detecting deviations in real-time, checkweigher machines help avoid costly recalls, minimize giveaway (overfilling), and maintain consistency.

Price variations in checkweighers stem from their ability to address specific operational challenges. Factors like accuracy and speed directly impact the total cost of ownership (TCO), including initial investment, maintenance, and long-term savings from reduced waste. At Samegram, our high-precision checkweighers are engineered to balance these factors, offering customizable solutions that integrate seamlessly into your production line. With over 5,000 successful installations worldwide, Samegram's expertise ensures you get value-driven equipment tailored to your needs.

Key Factors Influencing Inline Checkweigher Prices

Based on extensive industry analysis, here are the primary factors that determine inline checkweigher pricing. We'll break down each one, explaining how it affects costs and providing practical tips to solve common user problems like inconsistent weights or high rejection rates.

1. Capacity and Speed (Throughput)

Higher capacity and speed are vital for fast-paced production lines but increase costs due to advanced motors, sensors, and controls. For instance, a checkweigher combination system handling up to 180 pieces per minute require robust engineering to maintain accuracy at high speeds.

● Impact on Price: Basic models for low-speed lines (e.g., 5-40 m/min) are more affordable, while ultra-fast systems (up to 120 m/min or more) can be pricier due to enhanced components.

● Practical Solution: If your factory experiences bottlenecks, opt for dynamic (in-motion) checkweighers over static ones. This automates weighing and rejection, boosting efficiency and reducing labor costs by up to 40%, as seen in real-world applications.

● Samegram's Edge: Our SC series checkweighers achieve speeds of 180 pieces/min with weighing ranges from 0.1g to 80kg, making them ideal for high-volume food processing without compromising precision.

2. Accuracy and Sensitivity

Accuracy is paramount for compliance and waste reduction, influenced by sensor technology and environmental adaptations. Higher precision (e.g., ±0.05g) demands sophisticated calibration and components, elevating prices.

● Impact on Price: Standard accuracy models are budget-friendly, but those with high-resolution scales for challenging environments (e.g., wet or dusty areas) add costs for features like dust resistance or moisture protection.

● Practical Solution: Environmental factors like temperature fluctuations, humidity, or debris can degrade accuracy, leading to false rejections. Choose models with auto-re-zeroing and protective covers to maintain tolerances and avoid downtime. Regular calibration ensures long-term reliability, preventing issues like regulatory non-compliance.

● Samegram's Edge: Samegram's checkweighers offer accuracy from ±0.05g to ±10g, certified to MID and ISO standards. Our systems minimize errors in food production, improving qualification rates to 99.8% and supporting traceability for safer operations.

3. Technological Features and Integration

Advanced features like data logging, software connectivity (e.g., Ethernet/USB for histograms and charts), and modular designs enhance functionality but raise prices.

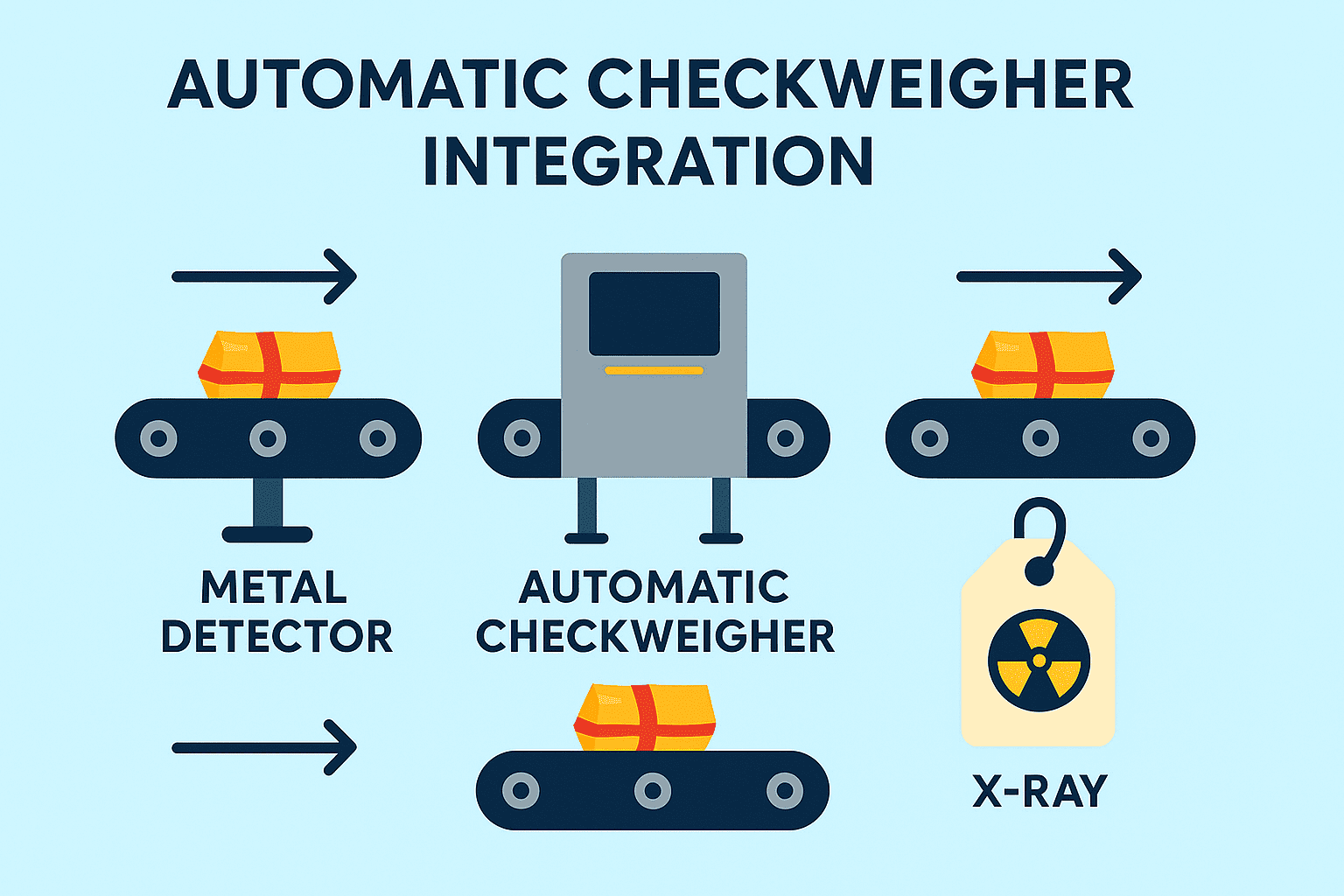

● Impact on Price: Basic standalone units are cheaper, while integrated systems combining checkweighers with metal detectors or X-ray scanners increase costs but lower TCO by reducing maintenance and space needs.

● Practical Solution: For factories needing seamless line integration, look for Industry 4.0-compatible models with AI-assisted inspection. This solves problems like manual data errors and enables real-time monitoring, cutting operational costs.

● Samegram's Edge: Our modular checkweighers support optional metal detection and labeling, with real-time data connectivity for smart factories. This customization ensures easy integration, as proven in pharmaceutical and logistics applications.

4. Material Quality and Build

The use of durable materials like stainless steel affects longevity and hygiene, especially in food environments prone to corrosion or cleaning.

● Impact on Price: Industrial-grade, flushable designs for harsh conditions (e.g., chlorinated or salty areas) are more expensive than basic builds.

● Practical Solution: In wet or corrosive settings, select USDA-certified, easy-to-clean models to prevent breakdowns and ensure GMP compliance. This addresses hygiene issues, reducing contamination risks and extending equipment life.

● Samegram's Edge: Built with stainless steel and ultra-hygienic designs, Samegram's checkweighers are perfect for food production, offering 12-month warranties and lifetime support for trustworthy performance.

5. Environmental Factors

Conditions like dust, moisture, air currents, or electrical noise require protective features, influencing design complexity and cost.

● Impact on Price: Standard models suit clean environments, but those with shields against debris or high-resolution scales for variable temperatures command higher prices.

● Practical Solution: Assess your factory's conditions—e.g., use dust-resistant covers in dusty areas—to avoid accuracy loss. Combination systems can consolidate inspections, solving space and error issues in contaminant-sensitive industries.

● Samegram's Edge: Our checkweighers handle diverse environments with features like high-speed precision algorithms, ensuring consistent performance in food factories.

6. Brand and Supplier Reputation

Well-known brands offer better support and quality, often at a premium, but provide value through reliability and after-sales service.

● Impact on Price: Established suppliers like Samegram may have higher upfront costs but deliver superior TCO via innovation and customization.

● Practical Solution: Prioritize brands with proven track records, free testing, and quick installation to resolve integration challenges and ensure ROI.

● Samegram's Edge: As a trusted checkweigher manufacturer with a focus on R&D, Samegram provides free sample testing, onsite demos, and sustainable designs that reduce waste and energy use.

| Factor | Price Impact | Practical Tip | Samegram Solution | |||

Capacity & Speed | High speed increases cost | Choose dynamic for high-volume lines | Up to 180 pcs/min for efficient food production | |||

Accuracy | Precision tech adds expense | Calibrate for environments | ±0.05g accuracy with auto features | |||

Features & Integration | Advanced options elevate price | Opt for modular designs | AI connectivity for smart factories | |||

| Material Quality | Durable builds are pricier | Select stainless for hygiene | Flushable, ISO-certified construction | |||

| Environmental Factors | Protections raise costs | Assess site conditions | Dust/moisture-resistant models | |||

| Brand Reputation | Premium for quality | Seek warranties & support | 12-month warranty, lifetime service | |||

How to Choose the Right High Speed Checkweigher for Your Needs

To solve real-world problems like weight inconsistencies or regulatory hurdles:

1. Define your production goals (e.g., speed, product type).

2. Evaluate environmental challenges (e.g., moisture in food lines).

3. Consider TCO, not just upfront price—features like easy maintenance save money long-term.

4. Test options: Samegram offers free sample testing to ensure fit.

By addressing these, you'll select an industrial checkweigher that enhances productivity and compliance.

SC-C is a can checkweigher designed for cans, jars, and bottles, which is a reliable online checkweigher machine for the production line.

Categories: Checkweigher

Brand: SameGram

Model: SC-C

Weighting section size: Non-standard customization

Belt speed: 5-90m/min

Applicable product size: Non-standard customization

Rejection mode: Customized

Storage formula: 100 types

Why Choose Samegram Automatic Checkweighers?

At Samegram, we are a high-tech enterprise dedicated to innovative weighing solutions, with expertise in dynamic checkweighers for industries like food and pharmaceuticals. Our High-Precision and Ultra-Fast Checkweigher series tackles price-influencing factors head-on, offering unmatched accuracy (±0.05g), speed (180 pcs/min), and integration. Backed by ISO certifications and a commitment to sustainability, our systems reduce labor costs, improve efficiency, and ensure product safety. Visit our product page or contact us for a customized quote.

Conclusion

Investing in a checkweigher involves balancing factors like speed, accuracy, and integration to meet your factory's needs. By understanding these elements, you can choose equipment that resolves weight compliance issues and boosts ROI. For expert guidance and high-quality solutions, trust Samegram—your partner in intelligent checkweighing. Explore our full range today.