Checkweigher Maintenance and Calibration: Essential Guide for Peak Performance

- Share

- Issue Time

- Aug 13,2025

Summary

Discover expert tips on checkweigher maintenance, calibration procedures, and troubleshooting common issues to boost performance in food, pharma, and logistics. Learn how SameGram's reliable dynamic checkweighers ensure compliance and minimize downtime—explore our solutions today.

As a leading provider of intelligent checkweigher solutions, SameGram understands the critical role that proper maintenance and calibration play in ensuring the accuracy, efficiency, and longevity of your in-motion checkweigher systems. With over 20 years of expertise in industrial automation weighing, we have delivered more than 5,000 units to clients in 60+ countries, helping industries like food, pharmaceuticals, and logistics achieve compliance and reduce downtime. In this comprehensive guide, we'll explore common checkweigher problems, factors affecting accuracy, maintenance best practices, and calibration procedures to optimize your operations. Whether you're using our high-precision checkweighers or similar equipment, these tips will help elevate your production line.

Dynamic checkweighers are vital for quality control, ensuring products meet weight specifications to avoid regulatory fines, product recalls, and customer dissatisfaction. Regular maintenance prevents mechanical failures, while precise calibration maintains accuracy amid environmental and operational challenges. Neglecting these can lead to costly errors, but with proactive care, you can minimize giveaway, enhance efficiency, and comply with standards like ISO, HACCP, and NMI.

At SameGram, our checkweighers feature modular designs, high-speed precision algorithms, and IP65-rated stainless steel construction for durability in harsh environments. Trusted by industry leaders, our systems integrate seamlessly with metal detectors and labeling for comprehensive inspection. Explore our checkweigher solutions to discover how we can tailor them to meet your specific needs.

Common Problems with In-Line Checkweighers and How to Fix Them

Drawing from industry insights, here are frequent issues that can disrupt In-line checkweigher performance, along with practical solutions. Early detection through routine checks can prevent downtime.

● Mechanical Wear and Tear: Components like load cells, motors, and belts degrade over time, causing inaccurate readings or jams.

Cause: High-volume usage or poor lubrication.

Solution: Inspect and replace worn parts regularly. Lubricate moving parts per manufacturer guidelines to extend lifespan.

● Conveyor Belt Misalignment or Blockages: Products may jam at high speeds, leading to invalid results.

Cause: Uneven product placement or debris buildup.

Solution: Clean belts daily, ensure products are centered, and install sensors for automatic shut-offs.

● Sensor and Electrical Failures: Loose sensors or power interruptions result in data jumps.

Cause: Faulty cables or surges.

Solution: Secure connections, upgrade grounding, and test sensors weekly.

● Software Glitches: Bugs or outdated firmware affect operations.

Cause: Lack of updates.

Solution: Install manufacturer updates promptly; contact support for diagnostics.

For expert troubleshooting, SameGram offers remote diagnostics and on-site repairs with a 12-month warranty and lifetime maintenance. Our combination systems, like those integrating inline checkweighers with metal detectors, minimize these issues through robust design—learn more.

SCL-10060L50 is an automatic weigh price labeler with scanning, weighing scale label printing, and template customization.

Categories Checkweigher Combination System

Brand: SameGram

Model: SCL-10060L50

Weighting range: 10-50g

Weighting accuracy: ±0.5-2g

Labeling speed: 15-25pcs/min

Labeling accuracy: ±5-10mm

Weighting section size: L 500mm*W 300mm

Applicable product size: L≤300mm; W≤300mm

Factors Affecting Checkweigher Combination System Accuracy

Accuracy is the cornerstone of effective checkweighing. Several variables can compromise it, but understanding them allows for targeted improvements.

| Factor | Description | Impact on Accuracy | Mitigation Tips | |||

Environmental Conditions | Temperature fluctuations, humidity (ideal: 30-85%), and vibrations from the line. | Alters load cell signals, causing voltage drops or added weight from vibrations. | Maintain stable conditions; use vibration-dampening mounts and follow manufacturer temperature guidelines. | |||

Product Variations | Inconsistent shapes, sizes, densities, or packaging textures. | Creates shifts or vibrations during weighing. | Standardize products where possible; calibrate for specific variations. | |||

| Conveyor Speed | High speeds reduce measurement time. | Increases errors from dust or instability. | Optimize speed for your setup; our high-speed checkweighers handle up to 180 m/min with ±0.02g precision. | |||

| Mechanical Wear | Loose fasteners, damaged load cells, or worn belts. | Leads to unstable readings. | Schedule regular inspections and part replacements. | |||

| Operational Errors | Improper setup or operator mishandling. | Results in configuration mistakes. | Provide thorough training; SameGram includes online sessions for seamless operation. | |||

By addressing these, you can achieve consistent results. SameGram's R&D-driven algorithms ensure superior accuracy even in challenging conditions, backed by certifications like CE and UL.

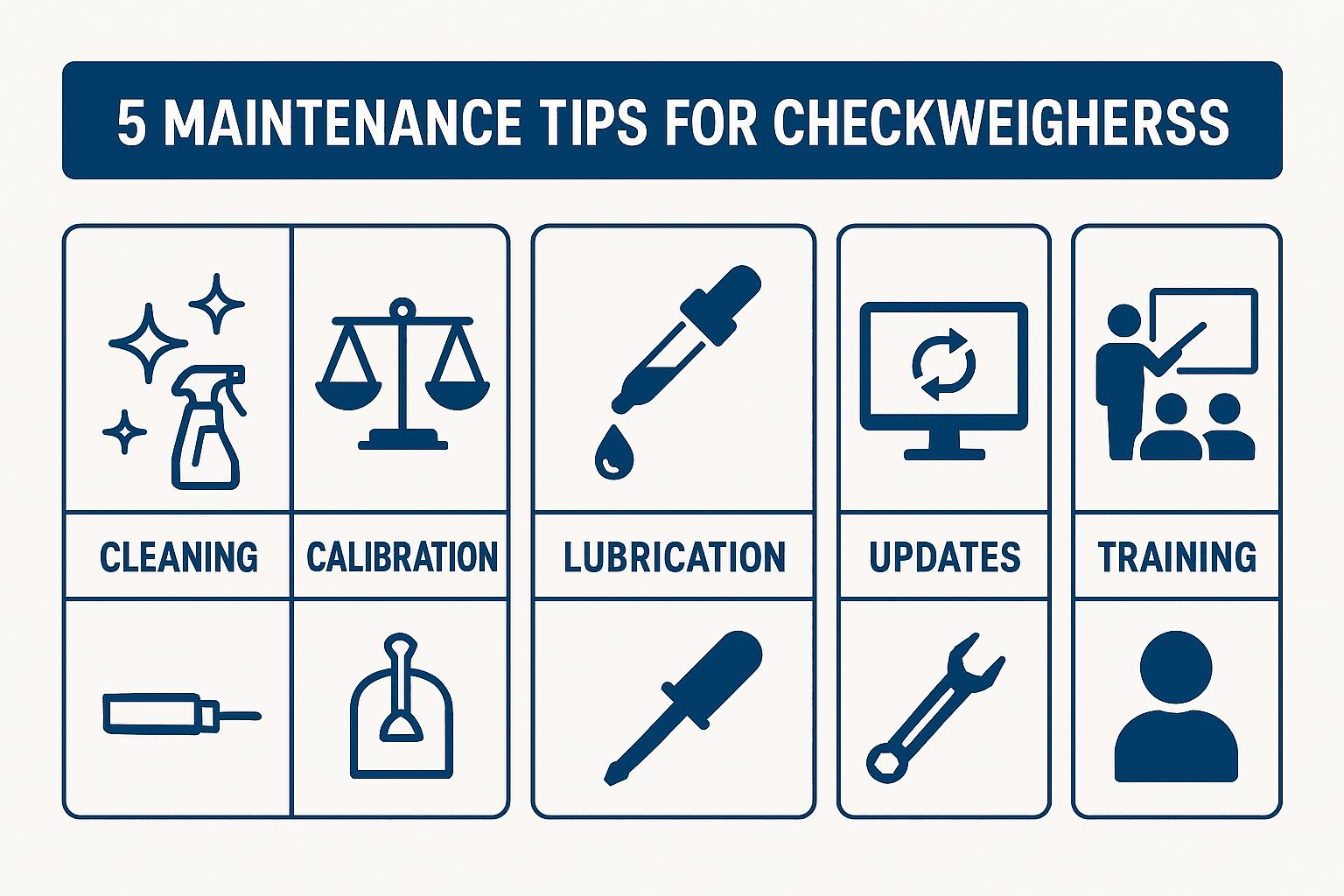

5 Basic Tips for Checkweigher Maintenance

To keep your checkweigher running smoothly, incorporate these proven tips into your routine:

1. Regular Cleaning and Inspection: Remove debris from belts, platforms, and sensors to prevent buildup. Inspect for wear daily.

2. Calibration and Verification: Use test weights to verify accuracy; calibrate per schedule to meet standards.

3. Lubrication and Belt Care: Apply lubricants as recommended; check for fraying and tension.

4. Software Updates: Install updates for bug fixes and enhancements.

5. Operator Training: Educate staff on procedures, reporting issues, and documentation.

These practices reduce downtime and extend equipment life. At SameGram, we offer preventive maintenance programs and free sample testing to tailor our checkweighers to your line—request a demo.

Step-by-Step Checkweigher Calibration Procedures

Calibration ensures your checkweigher meets tolerances and regulatory requirements. Follow this process for reliable results:

1. Preparation: Clean the system and ensure stable environmental conditions. Gather certified test weights matching your product range.

2. Zero Scale Setting: Reset to zero without products; enable active zero tracking.

3. Test Weighing: Run known weights through the system multiple times, recording results.

4. Adjustments: Fine-tune load cells or software if discrepancies arise; recalibrate for specific products.

5. Verification and Documentation: Confirm compliance with reports for audits; repeat quarterly or as needed.

Professional services, like those from SameGram, use advanced tools for precise calibration, minimizing giveaway. Our systems require less frequent calibration due to sensitive load cells—discover more.

Trust SameGram for Your Checkweigher Needs

With a commitment to innovation, quality, and sustainability, SameGram is your partner in intelligent weighing solutions. Our customizable checkweighers, backed by 5,000+ success stories, deliver speed, accuracy, and traceability for smart factories. From free on-site demonstrations to global 72-hour support, we ensure your operations thrive.

Ready to enhance your checkweigher maintenance and calibration? Contact us today for tailored advice or explore our full range.