Checkweigher Applications: Ensuring Precision and Compliance in Manufacturing

- Share

- Issue Time

- Aug 16,2025

Summary

Ensure regulatory compliance and production precision with advanced checkweigher applications. Discover integration tips and solutions for manufacturing lines.

Welcome to SameGram, your trusted partner in industrial automation weighing solutions. With over 20 years of expertise in R&D and manufacturing, SameGram specializes in high-precision checkweighers that integrate seamlessly into production lines across food, pharmaceuticals, logistics, and more. Our systems help businesses like yours achieve automated weight inspection, boost efficiency, and ensure product safety and compliance. Explore how checkweighers can transform your operations below.

A checkweigher is an automated machine designed to verify the weight of products during the manufacturing process, ensuring they meet predefined design specifications and regulatory standards. In factories, especially in food production, in-motion checkweighers play a critical role in quality control by detecting underweight or overweight items, preventing non-compliant products from reaching consumers. This not only safeguards brand reputation but also minimizes waste and legal risks.

At SameGram, our High-Precision and Ultra-Fast Checkweigher series exemplifies this technology. Certified to MID and ISO standards, these systems offer accuracy from ±0.05g to ±30g and speeds up to 180 pieces per minute, making them ideal for high-volume lines. Whether you're dealing with food packaging or pharmaceutical dosing, our checkweighers ensure every product conforms to norms like FDA regulations or EU directives.

Key Applications of Inline Checkweighers

Inline checkweighers are versatile tools applied across industries to solve real-world problems like inconsistent product weights, regulatory non-compliance, and production inefficiencies. Here's a detailed look at their applications, drawing from proven industry practices:

Food Industry Applications

In food manufacturing, food industry checkweighers ensure packaged products match label weights, reducing giveaway (overfilling) and preventing underfilling fines. They integrate into lines for raw materials, packaging, labeling, and sorting.

● Bakery & Confectionery: Weighing bread, pastries, and sweets to maintain portion consistency.

● Dairy, Meat & Poultry: Checking cheese blocks, yogurt, or poultry trays for accurate weights.

● Prepared Meals & Snacks: Verifying frozen meals, bagged salads, or chip bags to comply with average weight systems.

● Beverages & Sauces: Inspecting bottles, cans, or jars for correct fill levels.

For instance, in a food processing factory, our SameGram food safety checkweighers have helped clients like Panpan Foods achieve 99.8% accuracy, cutting labor costs by 40% through automated rejection and data logging.

Pharmaceutical Industry Applications

Precision is paramount in pharma to ensure dosage accuracy and patient safety. Checkweighers handle sampling, capsules, tablets, and more.

● Capsules & Tablets: 100% weighing with accuracy to detect under- or overfilled items.

● Individual Packaging (Sticks/Sachets): Compact inspection for space-saving on multi-lane lines.

● Small-Diameter Bottles & Aerosol Inhalers: Stable transfer and weighing for eye drops or inhalers.

● Multi-Lane Inspection: Centralized control for high-speed lines, compliant with CFR 21 Part 11 for data security.

SameGram's modular checkweighers support pharma needs with hygienic stainless steel designs, easy cleaning, and integration with metal detectors for contaminant-free production.

Other Industry Applications of Motion Checkweigher

Motion checkweighers extend beyond food and pharma, providing essential weight verification in diverse sectors to address challenges like product variability, compliance with packaging regulations, and operational efficiency. SameGram's robust systems, with capacities up to 80kg and industrial-grade durability, are tailored for these environments, offering features like stainless steel construction for harsh conditions and real-time data integration.

Cosmetics & Personal Care

In the beauty industry, checkweighers ensure precise filling of products to meet consumer expectations and regulatory standards, preventing underfilled items that could lead to complaints or recalls. Examples include weighing perfumes, lotions, shampoos, and creams in bottles or jars; inspecting stick packs or sachets for multi-track high-speed lines; verifying eye lotions, nasal drops, or compact cosmetics with high accuracy (±0.5g or better); and end-of-line checks for personal care items like soaps or deodorants to comply with weight labeling laws. Our SameGram checkweighers have enabled cosmetics manufacturers to achieve 99% compliance rates, reducing waste by automating rejection of non-conforming packages.

Logistics & Industrial

For logistics and heavy-duty industrial settings, checkweighers facilitate accurate in-motion weighing during shipping and assembly, ensuring parcels meet weight limits for transport and preventing overloads or errors in inventory. Key uses include inspecting automotive parts like bearings or components for precise material removal; weighing machinery assemblies or tools in production lines; verifying large parcels, boxes, or pallets up to 80kg in warehouses for shipping compliance; and dynamic checks in conveyor systems for real-time feedback on picking and packing processes. SameGram's heavy-load models support industrial clients in cutting shipping costs by 15-20% through precise weight verification and integration with logistics software.

Chemicals & Agriculture

In chemical and agricultural production, checkweighers handle bulk materials to ensure safe, accurate filling and adherence to safety standards, minimizing hazards from over- or under-filling. Applications encompass weighing bulk powders, fertilizers, or pesticides in bags or containers; inspecting aerosols, liquids, gases, or granular products like seeds for fill levels; verifying agricultural produce bags (e.g., fruits, grains) for market-ready weights; and compliance checks in chemical engineering for products like paints, adhesives, or cleaning agents. With SameGram's IP-rated, durable checkweighers, agricultural firms have improved yield accuracy, reducing material giveaway by up to 10% in powder handling operations.

These applications address user pain points like waste reduction—our systems minimize raw material loss by providing real-time feedback to adjust filling machines—and compliance, avoiding costly recalls.

Benefits of Using Automatic Checkweigher Machines

Implementing automatic checkweigher machines solves practical problems and delivers measurable ROI:

● Quality Assurance: Prevents defects by rejecting non-compliant items, enhancing customer satisfaction.

● Efficiency Gains: High-speed operation (up to 400 pcs/min) reduces downtime and labor, as seen in our 5,000+ installations worldwide.

● Waste Minimization: Accurate weighing cuts product giveaway by 10-20%, optimizing resources and boosting profits.

● Regulatory Compliance: Meets standards like FDA, USDA, and EU average weight directives, with data export for audits.

● Cost Savings: Integration with existing lines lowers maintenance needs; SameGram offers a 12-month warranty and lifetime support.

In one case, a Belarus food factory using our automatic production line checkweighers saw a 40% drop in labor costs and improved line efficiency.

Types of Products That Can Be Weighed by Dynamic Checkweighers

Checkweigher integration system handle diverse products, from grams to kilograms:

● Packaged Foods: Chips, frozen meals, baked goods.

● Pharma Items: Tablets, syrups, medical devices.

● Consumer Goods: Bottles, cans, cosmetics.

● Industrial: Parts, powders, large boxes.

Our SameGram models, like the SCP6 (0.1-100g range) or SC3-L-12080S60 (up to 80kg), adapt to any product with customizable belts and speeds up to 120m/min.

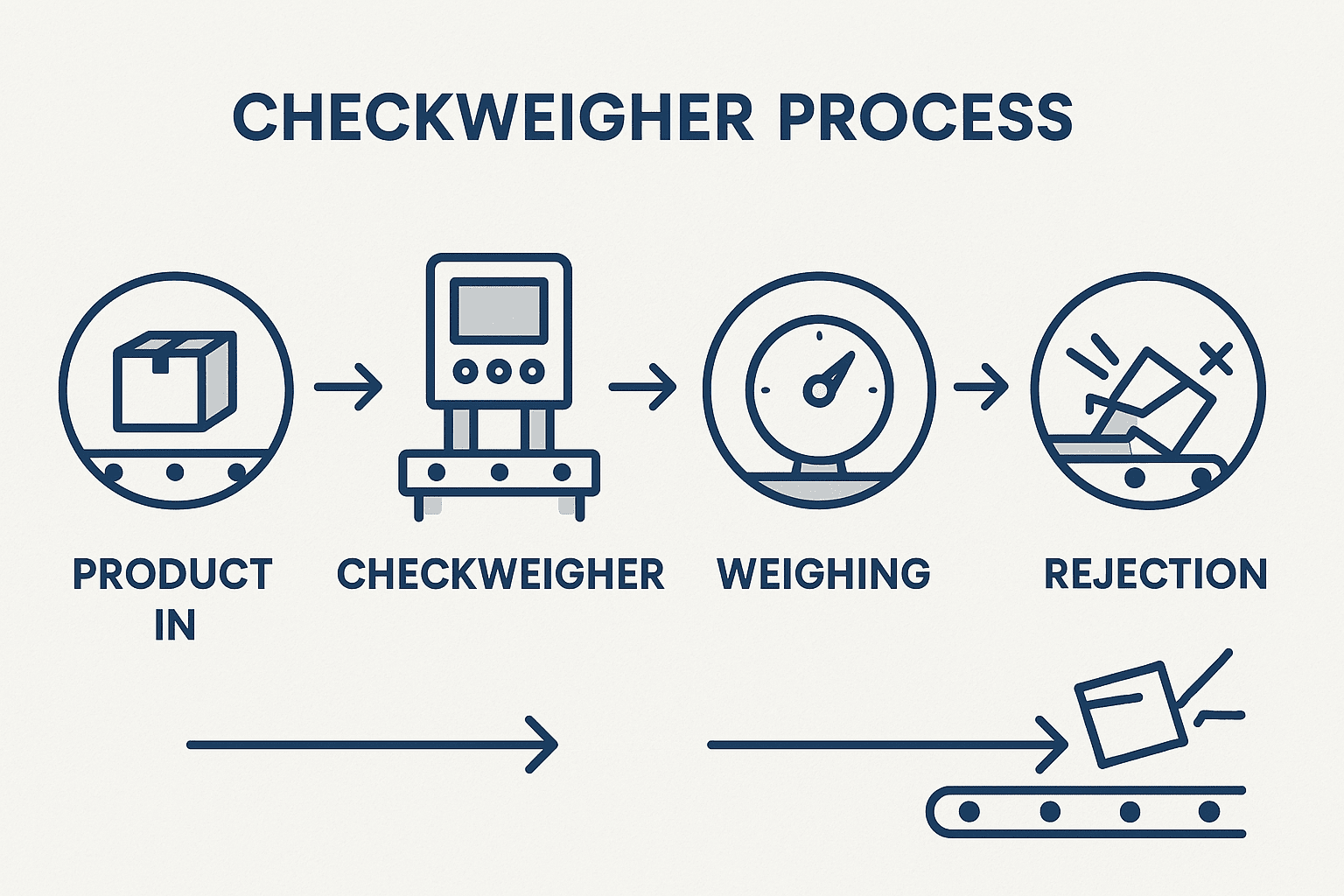

How Checkweigher Equipment Works: A Step-by-Step Guide

To help users understand and implement, here's how quality control weighing checkweighers operate:

1. Feeding: Products enter via conveyor, spaced for accuracy.

2. Weighing: High-speed load cells measure weight in motion.

3. Data Processing: Software compares against presets; non-compliant items are flagged.

4. Rejection: Automated arms or jets remove rejects.

5. Feedback: Data logs adjust upstream processes.

SameGram's systems feature user-friendly touchscreens, multi-language support, and Ethernet integration for real-time analytics.

Why Choose SameGram Checkweighers?

As a leader in intelligent weighing solutions, SameGram combines innovation with reliability. Our High-Precision and Ultra-Fast Checkweigher stands out with:

● Modular Design: Easy upgrades and integration with metal detectors or labelers.

● Hygienic Features: Stainless steel, IP-rated for washdown environments.

● Customization: Tailored for your line, with free sample testing and on-site demos.

● Global Support: Serving 60+ countries, with 72-hour response and remote diagnostics.

Visit our product page for specs: High-Precision Checkweigher.

Installation and Maintenance Tips

Proper setup ensures longevity:

● Align with manufacturer guidelines; SameGram provides on-site commissioning.

● Regular cleaning, calibration, and software updates prevent issues.

● Train operators— we offer virtual training for seamless adoption.

Conclusion: Elevate Your Production with SameGram

Checkweighers are essential for precision, compliance, and efficiency in manufacturing. By addressing weight inconsistencies, they solve key challenges like waste and recalls. At SameGram, we're committed to your success with cutting-edge solutions backed by 20 years of experience and 5,000+ satisfied customers.

Ready to optimize your line? Contact us for a free consultation or demo. Explore more at SameGram Homepage or About Us.